TFL Solve Rotary Seamer Turret’s Washdown-Induced Failures, Saving $287,000 per Year

"The most troublesome thing before was the can sealer of this line. It would frequently get stuck and alarm due to rusty bearings every few days. TFL Bearing promptly provided us with professional advice. After adopting TFL's solution, it has been rock-solid for over a year. We can finally focus on increasing production capacity!"

Home / Customer Cases / TFL Solve Rotary Seamer Turret’s Washdown-Induced Failures, Saving $287,000 per Year

TFL bearings help beverage co-packer save $287,000 a year

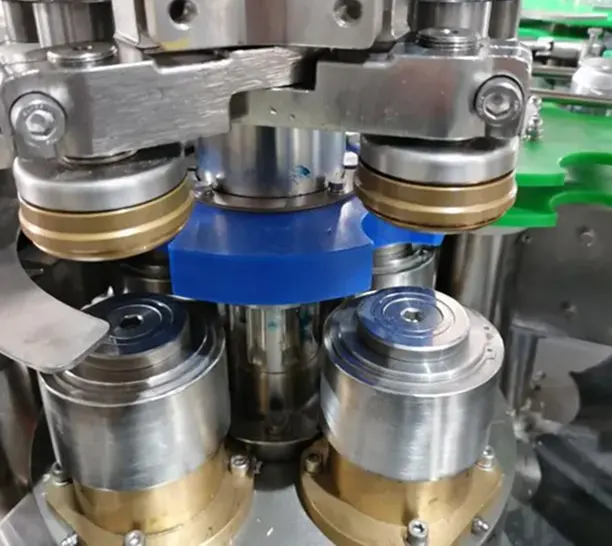

Rotary Seamer Turret

Cost Savings: $287,000

The beverage co-packer in Malaysia. Use the Rotary Seamer Turret on their high-speed can filling line. This turret is the heart of the production line. It operates at speeds of hundreds of cans per minute to precisely align and instantly crimp-seal the can lids onto the bodies, ensuring product integrity and shelf life.

However, bearings are often plagued by corrosion and lubrication failure, which directly affects the production efficiency and product quality.

"The most troublesome thing before was the can sealer of this line. It would frequently get stuck and alarm due to rusty bearings every few days. TFL Bearing promptly provided us with professional advice. After adopting TFL's solution, it has been rock-solid for over a year. We can finally focus on increasing production capacity!"

Key Facts

-

Corrosion from Frequent Washdowns & Sanitizers.

- The Mechanism: To comply with HACCP hygiene standards, the equipment undergoes a rigorous cleaning process with sanitizers containing sodium hypochlorite or quaternary ammonium after each production run. These caustic fluids would inevitably penetrate standard bearing seals, washing out the grease and directly corroding the rings and rolling elements.

- The Consequence: Rust spots would appear within weeks, leading to increased operational noise and eventually causing the bearings to seize, triggering unplanned line stoppages.

Contamination from Product Spillage.- The Mechanism: During high-speed filling, minor spillage of sugary or acidic juices is unavoidable. This sticky residue adheres to the bearing housings, compromises the elasticity of the bearing seals, and seeps inside. It then mixes with the internal grease, forming a viscous, abrasive paste.

- The Consequence: This led to unstable rotational torque, causing minute deviations in the seaming rollers' pressure and position. The result was defective seals (false seams), leading to product batches being rejected and increasing the risk of customer complaints.

Lubricant Breakdown from High-Temperature Steam.- The Mechanism: Certain processes require pasteurization cycles or cleaning with high-temperature steam. Under these repeated wet-heat conditions, standard grease would suffer from soap-base separation and oil oxidation, completely losing its lubricating properties and drying into a hard, caked residue.

- The Consequence: The resulting dry friction caused a rapid increase in bearing temperature, accelerating wear. The maintenance team was forced to adopt a reactive "replace-on-schedule" strategy, but bearings often failed prematurely in under two months, disrupting the entire production schedule.

The TFL Solution

TFL's engineering team addressed these pain points by replacing the conventional chrome steel bearings with a customized solution built around stainless steel bearings.

-

Comprehensive Corrosion-Resistant Material System: The inner/outer rings and rolling elements are all made from proven AISI 440C stainless steel, providing inherent resistance to chemical attack from sanitizers and acidic products. The cage was also upgraded to a corrosion-resistant stainless steel type to prevent premature failure.

-

Enhanced Double-Lip Contact Seals: We upgraded from standard single-lip seals to NBR (Nitrile) double-lip contact seals (2RS suffix). The inner lip effectively retains the grease, while the outer lip acts as a primary barrier to block and wipe away external liquids and sugary contaminants.

-

Food-Grade, Water-Resistant Lubricant: The bearings come pre-lubricated with an NSF H1-certified, calcium-sulfonate complex grease. This grease offers excellent resistance to water washout and high thermal stability, ensuring it does not emulsify or degrade in humid, high-temperature environments, thus providing reliable lubrication throughout the service life.

Product Features

-

Corrosion Resistant: Full AISI 440C stainless steel construction withstands sanitizers and acidic products.

-

Superior Sealing: Double-lip contact seals effectively block liquids and syrup.

-

Food-Grade Lubrication: Pre-filled with H1-certified, water-washout resistant grease.

-

Extended Service Life: Integrated design offers over 6x the lifespan of the original solution in wet and hot conditions.

Application effects

After adopting the TFL bearing solution, the customer's rotary seaming turrets have been significantly improved with remarkable results:

-

Before: Standard bearings lasted only 2 months, with frequent failures from rust and seizure. The seamer turret was a constant source of trouble on monthly maintenance reports, forcing operators to listen for warning signs and prepare for emergency repairs.

-

After: TFL's stainless steel solution, with its dual-layer protection (material resistance + physical sealing), provides reliable performance in harsh conditions. Bearing life is now consistently over 12 months, enabling a predictable, annual preventive maintenance schedule. Seaming quality improved dramatically, with the product defect rate dropping from 0.9% to 0.2%.

Cost-Savings Breakdown

By providing customers with customized bearing solutions, TFL Bearing successfully helped them solve problems in seamer turret operation, achieved a comprehensive improvement in equipment performance, and created significant value for them.

| REDUCED SPARE PART COSTS | $1,200 |

| ELIMINATED UNPLANNED DOWNTIME COSTS | $100,000 |

| MINIMIZED PRODUCT SCRAP LOSSES | $175,00 |

| ANNUALIZED COST SAVINGS | $287,000 |

About TFL BEARINGS

Why is TFL BEARINGS frequently chosen as the specified bearing brand bymajor international companies?

Reliable Operation Starts Here

Contact TFL Bearings for the Best Solutions!

Supply Chain Advantages

Our efficient global supply chain and inventory management ensure fast response and timely delivery.

Customized Solutions

We tailor bearing solutions to unique needs. Services include design advice & custom specifications for your specific application.

Cost Advantage

Competitive prices. Quality bearings meet int'l stds; interchangeable. Reliable, economical alternative. Lower costs, keep performance & value.

Reliable Service Assurance

Quality products plus reliable full service. Our pro team offers support from selection to after-sales. We aim to be your trusted partner.