TFL bearing solution saves $136,000 Annually on Paper machine

VFD Motor

Our client is a well-established, mid-sized specialty paper manufacturer in Germany, renowned for its high-quality coated paper and paperboard.

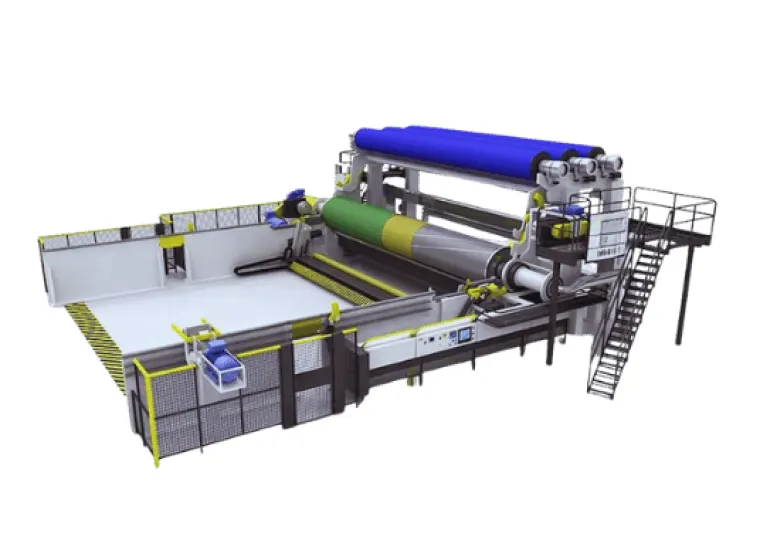

The core equipment in this case is the main AC variable frequency drive (VFD) motor for the press section of their No. 2 paper machine. This high-power motor is the heart of their entire production line. It uses a VFD to precisely control the speed and tension of the press rolls, which mechanically squeeze water out of the wet paper web. This step is critical for the paper’s final strength, smoothness, and overall production efficiency. In the continuous process of papermaking, any unplanned downtime of this motor means the entire line stops, leading to massive financial losses.

Key Facts

-

Electrical Erosion & Production Loss

The VFD was creating electrical sparks that eroded the bearing raceways, causing a "fluting" damage pattern. This resulted in a noticeable "hissing" sound and severe vibration, which degraded paper quality and forced a 10% production speed reduction to avoid further damage. -

Grease Breakdown & Overheating

The intense heat from the electrical discharges was burning the grease, turning it into a thick, black carbon residue. This destroyed its lubricating properties, causing the bearings to overheat and run dangerously hot, putting the entire motor at risk of a catastrophic seizure. -

Unpredictable Failures & Soaring Costs

Bearings failed randomly, sometimes in less than six months, making preventive maintenance schedules useless. This forced the team into a constant "firefighting" mode, leading to unplanned downtime, high costs for spare motor inventory, and missed customer delivery dates.

The TFL Solution

-

Bearing Type: TFL 6220/C3VL0241 Electrically Insulated Deep Groove Ball Bearing

- Aluminum Oxide Insulating Coating: A dense, durable layer of aluminum oxide (Al₂O₃) ceramic is applied to the outer surface of the bearing's outer ring using a proven plasma-spray process. This coating acts as a powerful electrical insulator (withstanding up to 3,000V DC), effectively breaking the path for stray shaft currents. It stops electrical erosion at its source.

- High-Performance Polyurea Grease: The bearings are pre-lubricated with a premium polyurea-based grease optimized for electric motor applications. This grease offers excellent high-temperature stability and shear resistance, maintaining a protective oil film even under continuous, hot-running conditions to extend lubrication life.

- Enhanced NBR Contact Seals: Fitted with double-lip contact seals made from durable, oil-resistant nitrile rubber (NBR). These provide a superior barrier against the moisture and fine paper dust common in the mill environment, protecting the bearing's internal components and ensuring long-term performance.

Product Features

- Stops Electrical Damage: "Ceramic armor" on the outer ring blocks harmful currents.

- Long-Life Grease: Premium grease resists high temperatures without breaking down.

- Superior Sealing: Double-lip seals keep dust and moisture out.

- Robust Performance: Optimized internal design for higher load capacity.

- Easy Installation: A drop-in replacement with the same dimensions as standard bearings. No modifications needed.

Application effects

- Before: The old bearings would start "hissing" in less than six months. The online monitoring system was always flashing yellow alerts, and everyone felt on edge. The plant manager had to slow down the machine just to maintain paper quality, and they could never hit their monthly production targets.

- Now: With the TFL insulated bearings installed, the motor runs as quiet and cool as the day it was new. The aluminum oxide coating completely blocks the stray currents, so the raceways stay perfectly smooth. The production line is now running consistently at its full design speed. The maintenance team reports that bearing housing temperatures are down by 15°C. Best of all, these bearings have been running trouble-free for over two years, achieving their full expected service life and reducing the annual failure rate by over 80%.

Cost-Savings Breakdown

| REDUCED SPARE PARTS COSTS | $6,000 |

| SAVED DOWNTIME LOSSES | $120,000 |

| LOWER PRODUCT SCRAP | $10,000 |

| TOTAL ANNUAL SAVINGS | $136,000 |

About TFL BEARINGS

Why is TFL BEARINGS frequently chosen as the specified bearing brand bymajor international companies?

Reliable Operation Starts Here

Contact TFL Bearings for the Best Solutions!

Our efficient global supply chain and inventory management ensure fast response and timely delivery.

We tailor bearing solutions to unique needs. Services include design advice & custom specifications for your specific application.

Competitive prices. Quality bearings meet int'l stds; interchangeable. Reliable, economical alternative. Lower costs, keep performance & value.

Quality products plus reliable full service. Our pro team offers support from selection to after-sales. We aim to be your trusted partner.