TFL bearing solution saves $314,500 per year on Continuous Casters

Segment Roll

A renowned mid-sized European producer of specialty steels, supplying high-grade plates to the demanding automotive and aerospace industries.

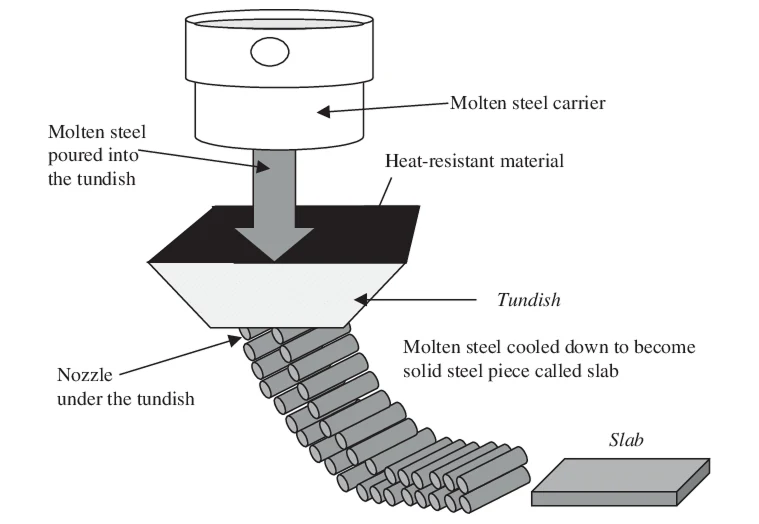

At the core of their production is a slab continuous caster, where the segment rolls perform the most critical function. This section is the heart of the line, responsible for supporting, guiding, and cooling the red-hot steel slab as it solidifies from a liquid to a solid state. With increasing market demands for quality and on-time delivery, any unplanned caster downtime translates directly into massive production losses and the risk of contractual penalties.

Key Facts

- The bearings on the customer's segment rolls faced a brutal operating environment, resulting in an average service life of less than eight months and causing frequent, costly unplanned shutdowns.

-

The Dual Attack of Water and Scale

- Failure Mechanism: Standard bearing seals quickly degraded under the heat and abrasion, allowing water and hard scale particles to penetrate the bearing. The grease was washed out and emulsified, while the scale created pitting and scratches on the raceways.

- Consequence: This led to a sharp increase in rotational friction, eventual bearing seizure, and damage to the roll surface, causing defects on the final steel product and triggering customer claims.

-

Extreme Thermal Stress

- Failure Mechanism: This large temperature differential caused drastic changes in the bearing's internal clearance, creating immense thermal stress. The material structure became brittle from the repeated cycles of expansion and contraction, leading to micro-cracks.

- Consequence: Bearings suffered from premature fatigue spalling under heavy loads, indicated by rising vibration levels. This forced early, unscheduled replacements to prevent catastrophic roll failure, disrupting the entire maintenance schedule.

The TFL Solution

-

Bearing Type: 23130 CCK/C4W33S1 2HRS

-

Reinforced Dual Sealing System (Suffix: 2HRS):

The bearing is equipped with a high-temperature, wear-resistant FKM (fluoroelastomer) double-lip contact seal. This is protected by an external stamped steel shield plate. This "contact + labyrinth" sealing combination forms a robust barrier against high-pressure water and solid contaminants. -

High-Temperature Design & Optimized Clearance (Suffixes: S1+C4):

The bearing rings undergo a special S1 dimensional stabilization heat treatment, ensuring they remain stable at operating temperatures up to 200°C (392°F). This is paired with a larger C4 radial internal clearance to safely accommodate the significant thermal expansion, preventing internal overloading and seizure. -

Durable Surface Phosphate Coating:

All external surfaces of the bearing are treated with a micro-porous phosphate coating. This mature process provides excellent rust resistance in high-humidity environments and helps retain grease during the critical initial run-in period, offering long-lasting protection.

Product Features

- Superior Contamination Shield (2HRS): FKM double-lip seal + shield plate.

- Built for Thermal Shock (S1+C4): Special heat treatment + optimized large clearance.

- Heavy-Duty & Easy Mounting (CC/K): Reinforced internal design and tapered bore.

- Corrosion Resistant: Comprehensive phosphate coating for harsh, wet conditions.

Application effects

Before:

Bearings on the segment rolls failed in just 6-8 months due to contamination or spalling. This led to at least 2-3 emergency shutdowns per year. Each repair was a high-pressure “firefight” for the maintenance crew, constantly disrupting the production schedule.

Now:

- The TFL 23130’s 2HRS seal successfully blocks over 95% of water and scale, keeping the grease clean throughout the bearing’s life.

- The combination of S1 heat treatment and C4 clearance effectively counters thermal stress, resulting in smooth operation and consistently low vibration readings.

- The average bearing service life has been reliably extended to over 24 months, aligning perfectly with the caster’s major maintenance schedule. Unplanned downtime from bearing failures has been virtually eliminated, transforming the maintenance team from firefighters into proactive planners.

Cost-Savings Breakdown

| REDUCED SPARE PART COSTS | $62,500 |

| ELIMINATED DOWNTIME LOSSES | $240,000 |

| LOWERED SCRAP & REWORK COSTS | $12,000 |

| TOTAL ANNUAL SAVINGS | $314,500 |

About TFL BEARINGS

Why is TFL BEARINGS frequently chosen as the specified bearing brand bymajor international companies?

Reliable Operation Starts Here

Contact TFL Bearings for the Best Solutions!

Our efficient global supply chain and inventory management ensure fast response and timely delivery.

We tailor bearing solutions to unique needs. Services include design advice & custom specifications for your specific application.

Competitive prices. Quality bearings meet int'l stds; interchangeable. Reliable, economical alternative. Lower costs, keep performance & value.

Quality products plus reliable full service. Our pro team offers support from selection to after-sales. We aim to be your trusted partner.