TFL bearing solution saves $27,600 per year on Spindle

CNC Machine

A mid-sized precision parts manufacturer in South Africa, serving the demanding aerospace and medical industries. The company operates a fleet of vertical CNC machining centers from a well-known brand.

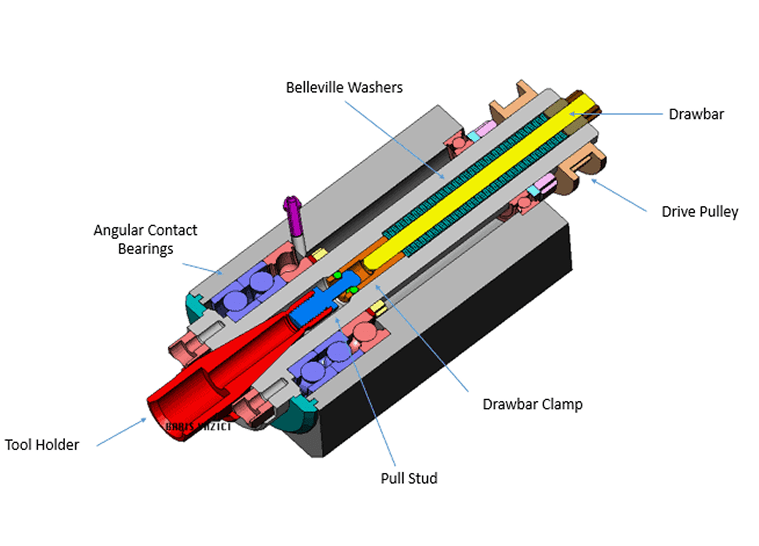

The spindle is the “heart” of the machine tool. It drives the cutting tool at speeds up to 18,000 RPM for high-precision milling and drilling. The spindle’s rotational accuracy, rigidity, and thermal stability directly determine the final part’s dimensional tolerance and surface finish.

Key Facts

-

Thermal Growth & Inaccuracy at High Speeds

- How it Happens: This heat causes micro-level thermal expansion in the spindle shaft and bearing rings. This changes the bearing preload and affects the tool tip position, leading to Z-axis inaccuracy.

- The Consequence: When machining deep holes or complex surfaces, parts were often produced out of tolerance, resulting in scrap. Operators were forced to run at lower speeds or frequently compensate for thermal changes, hurting productivity.

-

Coolant Contamination & Premature Failure

- How it Happens: Fine coolant mist seeped past the spindle's labyrinth seals and into the bearings. This contaminated the grease, washing it out and reducing its lubricating properties. Additives in the coolant also caused corrosion on the bearing raceways.

- The Consequence: The bearings became noisy, vibrated, and failed in just 8-10 months—far short of their expected life. This required costly and time-consuming spindle rebuilds, causing significant downtime.

-

Micro-Vibrations & Poor Surface Finish

- How it Happens: The mass of the steel balls created high-frequency micro-vibrations under intense centrifugal force. This vibration transferred from the spindle to the cutting tool, creating visible "chatter marks" on the workpiece surface.

- The Consequence: Even if dimensions were correct, the part surface had visible ripples. This failed to meet the strict quality standards for medical and aerospace parts, leading to customer complaints and rejected shipments.

The TFL Solution

-

Bearing Type: 7012 ACE/HCP4A (Hybrid Ceramic, 15° Contact Angle, P4A Precision)

-

G5 Silicon Nitride Ceramic Balls: We replaced the standard steel balls. Ceramic balls are 60% lighter, which significantly reduces centrifugal force, heat generation, and vibration at high speeds. Their extremely low thermal expansion coefficient greatly improves the spindle's thermal stability.

-

Optimized Internal Design & Superfinished Raceways: Using mature analysis methods, we optimized the bearing's internal geometry to increase rigidity. A superfinishing process creates an ultra-smooth raceway surface, which further reduces friction and sources of vibration.

-

Integrated Non-Contact Seals: We added custom-designed, non-contact seals to both sides of the bearing. These seals effectively block over 95% of coolant mist and contaminants without adding friction or limiting the spindle's maximum speed.

Product Features

-

Faster Speeds: Lighter ceramic balls mean less heat buildup.

-

Better Accuracy: Minimal thermal expansion keeps your tool tip precisely where it needs to be.

-

Contamination Shield: Integrated seals protect the bearing's grease from coolant.

-

Longer Life: Ceramic balls are harder and more wear-resistant, paired with high-purity steel rings.

-

Superior Finish: Lower vibration levels eliminate chatter marks for a smoother surface.

Application effects

Before: “The spindle would overheat when running above 12,000 RPM, and our finished parts often had visible chatter marks. We had to lower our speeds to get acceptable quality. Worse, a bearing would fail from coolant contamination every 8-10 months, causing 2-3 days of downtime for a rebuild and disrupting our entire production schedule.”

After: “With the TFL hybrid ceramic bearings, the spindle runs cool and stable even at its maximum 18,000 RPM. The thermal growth issue is gone. The non-contact seals have completely solved the coolant problem. Most importantly, our machining accuracy and surface finish have improved dramatically. Bearing life now easily exceeds 24 months, fitting perfectly into our planned maintenance cycle. Our maintenance team is thrilled.”

Cost-Savings Breakdown

| REDUCED MAINTENANCE & SPARES | $10,000 |

| INCREASED UPTIME & PRODUCTION | $9,600 |

| LOWER SCRAP & REWORK COSTS | $8,000 |

| TOTAL ANNUAL SAVINGS | $27,600 |

About TFL BEARINGS

Why is TFL BEARINGS frequently chosen as the specified bearing brand bymajor international companies?

Reliable Operation Starts Here

Contact TFL Bearings for the Best Solutions!

Our efficient global supply chain and inventory management ensure fast response and timely delivery.

We tailor bearing solutions to unique needs. Services include design advice & custom specifications for your specific application.

Competitive prices. Quality bearings meet int'l stds; interchangeable. Reliable, economical alternative. Lower costs, keep performance & value.

Quality products plus reliable full service. Our pro team offers support from selection to after-sales. We aim to be your trusted partner.