TFL Roller bearing solution saves $580,000 in total cost annually

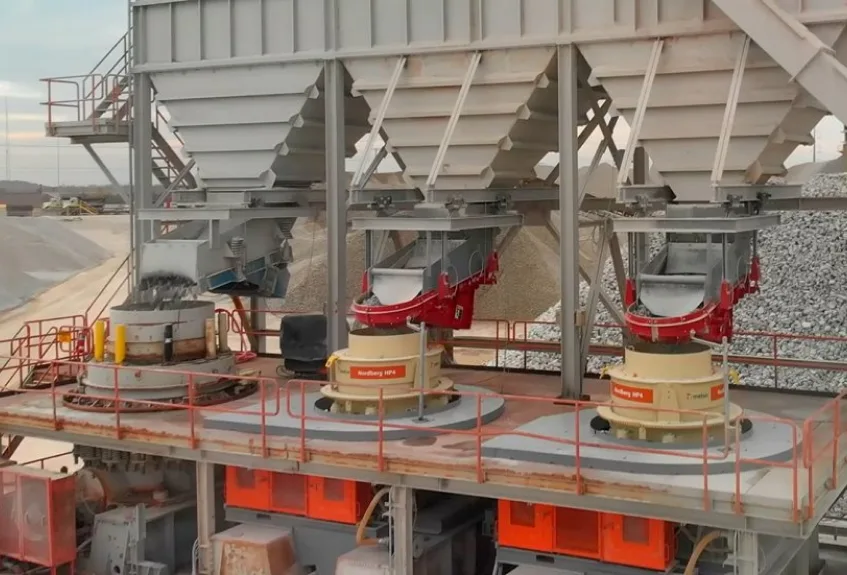

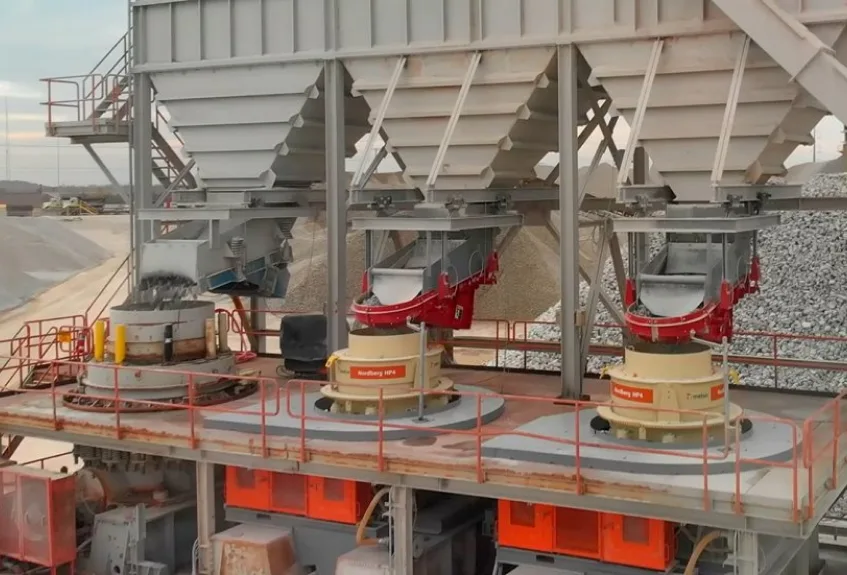

Crusher machine

Key Facts

-

Frequent bearing failure:

The average lifespan of the original bearings is only 3 months (industry average: 8-12 months), with each crusher requiring bearing replacement 4 times a year.

-

Downtime losses are fatal:

Each bearing failure leads to a 32-hour production halt, resulting in an annual loss of 8,700 tons of production capacity (equivalent to a reduction of $360,000 in annual revenue).

-

Harsh operating conditions:

- On-site dust concentration exceeds 400mg/m³ (ISO 4406 cleanliness grade -/22/18).

- Equipment vibration values reach 6.2mm/s (200% over the ISO 10816-3 standard limit).

-

Limited maintenance resources:

Only 2 maintenance engineers are responsible for the entire line of equipment, making it impossible to implement precise lubrication management.

The TFL Solution

Based on the actual situation of the customer, TFL Bearing quickly identified the root cause of the failure and provided a dedicated bearing solution for the customer:

-

The dual-fortress dynamic seal (rubber double-lip seal + rotating labyrinth groove) completely blocks dust intrusion and ends the early failure caused by grease contamination.

-

The shock-resistant core (ultra-high purity steel substrate + logarithmic profiled roller contour) optimizes stress distribution and eliminates raceway spalling caused by impact loads.

-

The self-sustaining lubrication ecosystem (roller micro-texture oil storage + oil channel network + high-temperature extreme pressure grease) ensures the continuous integrity of the grease film and overcomes the problem of high-temperature drying.

-

The wide-range adaptive self-aligning structure

(super-precision raceway ±1.5° deflection compensation)

actively absorbs equipment deformation deviations and eliminates eccentric load wear.

Product Features

- Lip contact seal + dust-proof labyrinth groove: Dust seal reliability

- Super-clean bearing steel (inclusion grade ≤ K4): Extended fatigue life

- Reinforced roller end design (impact resistance increased by 30%): Withstand instantaneous overload

- Symmetrical spherical raceway (angle compensation ±1.5°): Compensate for shaft installation deviation

- Copper alloy cage (high-temperature resistance up to 150°C): Adapt to high-temperature working conditions

- Optimized oil guiding groove (lubrication efficiency increased by 40%): Reduce the frequency of manual grease replenishment

Application effects

This mining operation was once mired in a predicament of short-lived bearings (lasting only 3 months), 128 hours of annual downtime, and a cost of $0.48 per ton. After the implementation of TFL’s customized bearing system, the bearing lifespan saw a 300% leap to 12 months, all downtime was eliminated, and the cost per ton plummeted by 42% to $0.28. Moreover, it pushed the hourly production capacity of a single line to exceed 95 tons. This set of data not only validates the effectiveness of technologies such as sealed anti-noise and anti-shock cores but also marks the strategic transformation of a medium-sized mining enterprise from a “repair quagmire” to “continuous production”.

| INDICATOR | BEFORE IMPROVEMENT | AFTER TFL SOLUTION | IMPROVEMENT RATE |

| AVERAGE BEARING LIFESPAN | 3 MONTHS | 12 MONTHS | +300% |

| ANNUAL DOWNTIME DUE TO FAULTS | 128 HOURS | 0 HOURS | -100% |

| HOURLY PRODUCTION CAPACITY PER LINE | 85 TONS | 95 TONS | +11.8% |

| MAINTENANCE COST PER TON OF AGGREGATE | $0.48 | $0.28 | -42% |

Cost-Savings Breakdown

ANNUAL EQUIPMENT FAILURE | ≤2 |

ENGINEER WORKLOAD | -50% |

QUALITY LOSS REDUCED | $580,000 |

About TFL BEARINGS

Why is TFL BEARINGS frequently chosen as the specified bearing brand bymajor international companies?

Reliable Operation Starts Here

Contact TFL Bearings for the Best Solutions!

Our efficient global supply chain and inventory management ensure fast response and timely delivery.

We tailor bearing solutions to unique needs. Services include design advice & custom specifications for your specific application.

Competitive prices. Quality bearings meet int'l stds; interchangeable. Reliable, economical alternative. Lower costs, keep performance & value.

Quality products plus reliable full service. Our pro team offers support from selection to after-sales. We aim to be your trusted partner.