TFL hybrid ceramic bearing solution saves $134,000 in total cost annually

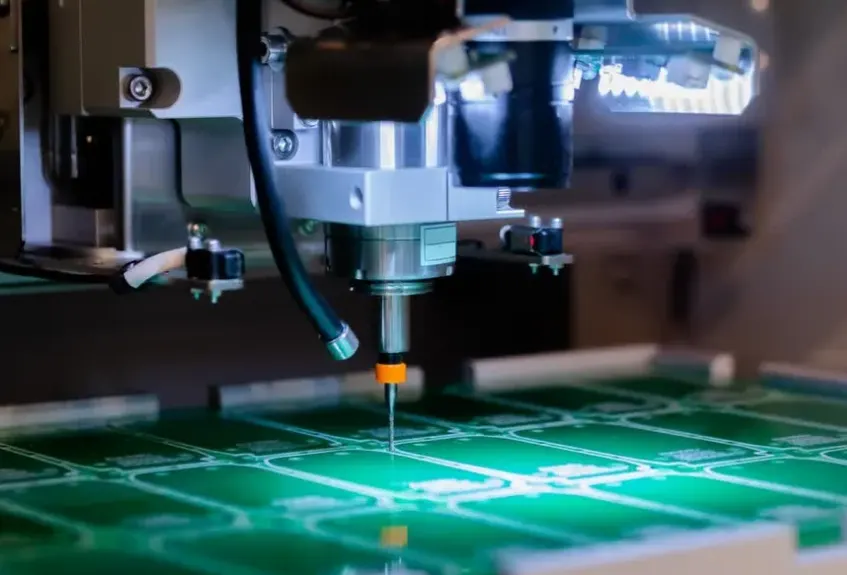

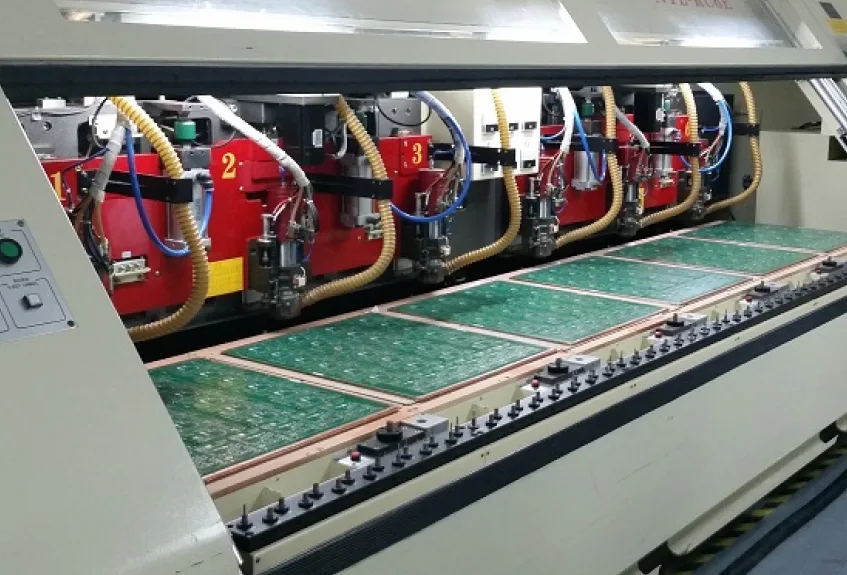

PCB drilling machine

Key Facts

-

Thermal Overload Shutdown: After the main shaft ran continuously at full load (180,000 rpm) for 40 minutes, the temperature rise at the front bearing position exceeded 65℃, triggering an overheating alarm and causing the equipment to shut down.

-

Excessive Maintenance Costs from Short Bearing Life: The average lifespan of the bearings was only six months (approximately 2,500 hours), and frequent replacements led to production line halts, with each maintenance costing over $2,774.

-

Precision Degradation in HDI Processing: When processing high-density HDI boards, due to thermal deformation, the drilling position accuracy drifted by ±8μm, and the scrap rate rose to 3.5%.

The TFL Solution

-

Bearing Technical Configuration:

-

Rolling elements: Silicon nitride ceramic balls

-

Inner and outer rings: Carburized steel

-

Preload scheme: Light preload, suitable for high-speed centrifugal expansion compensation

-

Temperature range: -30 to 150℃

-

Modification steps:

-

Replace the original two sets of steel ball bearings (back-to-back configuration) at the front end of the main shaft with TFL hybrid ceramic bearings;

-

Optimize the oil-air lubrication pipeline to direct the oil mist spray to the contact area of the bearing raceway;

-

Install a temperature sensor (PT100) to monitor the temperature of the outer ring of the bearing in real time.

Product Features

- High-strength alloy steel rings, Hardness ≥60 HRC, 50% longer fatigue life

-

Silicon Nitride (Si₃N₄) ceramic balls, density 3.2g/cm³ (60% lighter than steel), 40% higher speed limit

- Thermal stability optimization

- High-precision window cage (PEEK composite)

- Dedicated high-speed spindle grease

- P4 super-precision grade

Application effects

- Revolutionary Precision Enhancement

The P4S ultra-precision manufacturing of TFL hybrid ceramic bearings has compressed the spindle position accuracy drift from ±8μm to ±2.5μm (a 220% improvement in precision control). In PCB micro-hole processing, it achieves a 100% qualification rate for ±5μm hole position tolerance and reduces the scrap rate by 76%, helping customers break through the manufacturing bottleneck of high-density HDI boards. - Leap in Service Life

The collaborative design of silicon nitride ceramic balls and hardened alloy steel tracks has extended the continuous operation life of the bearings from 2,500 hours to over 12,000 hours (a 380% increase in lifespan). The average annual bearing replacement frequency per unit has dropped from 4.8 times to 0.9 times, reducing maintenance costs by 79% and fully unleashing the production capacity of high-value equipment. - Breakthrough in Thermal Control

The combination of ceramic material with a super-low thermal expansion coefficient of 0.8×10⁻⁶/K and a high-speed lubrication system has reduced the temperature rise under 180,000 rpm conditions from 65°C (triggering an alarm) to a stable 43°C (a 34% reduction in temperature increase). It eliminates the 0.1mm-level drilling depth deviation caused by spindle thermal elongation and keeps the roughness Ra value of multi-layer board hole walls stable at ≤1.2μm. - Energy Efficiency and Productivity Upgrade

Optimizing the raceway surface to reduce friction torque has lowered power consumption under the same working conditions from 4.2kW to 3.6kW (a 14.3% reduction in energy consumption). Coupled with a 33% increase in the maximum rotational speed (180,000rpm to 240,000rpm), the processing cycle has been shortened by 22%, and the comprehensive energy efficiency of the equipment capable of producing 720,000 PCBs annually has improved by 37%.

Cost-Savings Breakdown

DAILY PRODUCTION CAPACITY | +25% |

ANNUAL MAINTENANCE COST REDUCED | $16,000 |

QUALITY LOSS REDUCED | $118,000 |

TOTAL COST REDUCTION | $134,000 |

About TFL BEARINGS

Why is TFL BEARINGS frequently chosen as the specified bearing brand bymajor international companies?

Reliable Operation Starts Here

Contact TFL Bearings for the Best Solutions!

Our efficient global supply chain and inventory management ensure fast response and timely delivery.

We tailor bearing solutions to unique needs. Services include design advice & custom specifications for your specific application.

Competitive prices. Quality bearings meet int'l stds; interchangeable. Reliable, economical alternative. Lower costs, keep performance & value.

Quality products plus reliable full service. Our pro team offers support from selection to after-sales. We aim to be your trusted partner.