TFL bearing solution saves $21,000 per year on Servo Motor

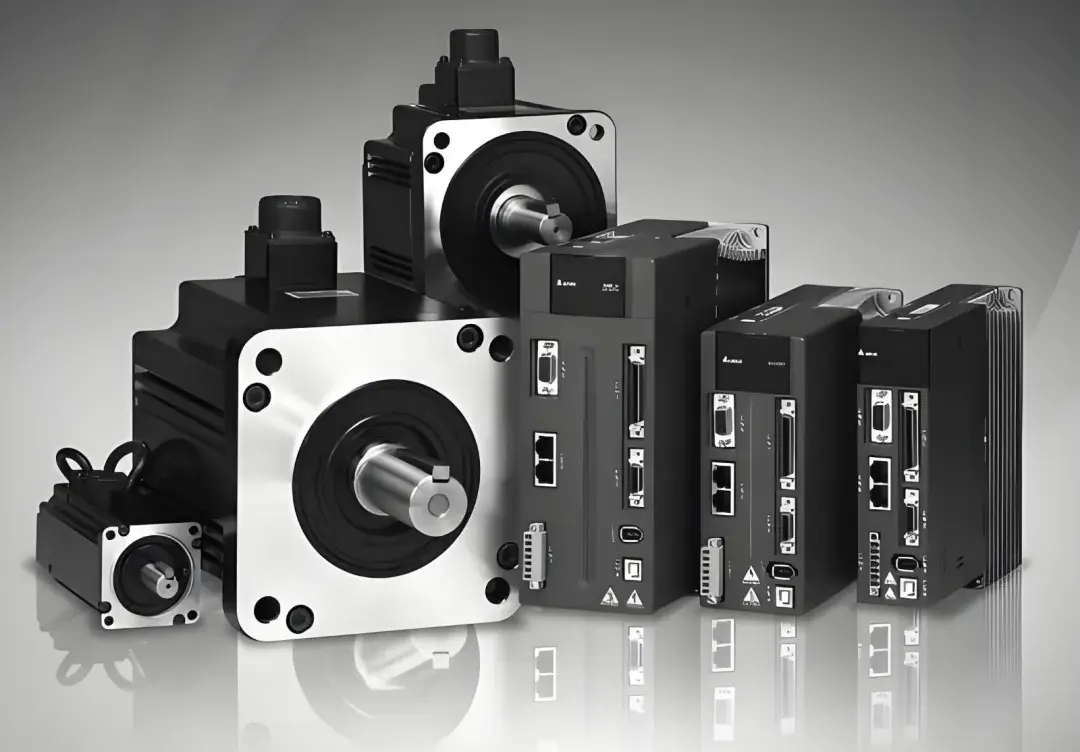

Servo Motor

A large German automation equipment company is focused on industrial automation equipment research and development and production of enterprises; its products are widely used in electronics manufacturing, automotive parts processing, logistics and warehousing, and other fields. Its production of servo motor equipment as the core drive components of the automation production line, the precision, stability, and operational efficiency. However, with the increasingly fierce competition in the market, the customer is facing the double pressure of reducing production costs and improving product quality; the original servo motor bearing system is gradually difficult to meet the needs of its business development.

Key Facts

- Decrease in Precision: After a period of operation, the clearance of the bearings increases, resulting in a decrease in the rotational precision of the motor, which affects the machining precision and positioning accuracy of the equipment on the workpiece, and the scrap rate rises gradually.

- Shorter Life: Frequent start-stop and high-load operation cause the bearings to wear and tear; the average service life is only about 6 months. The need for frequent replacement of bearings not only increases the maintenance costs but also leads to prolonged downtime of the equipment, affecting the production efficiency.

- Serious Heat: In high-speed operation, the bearing's internal friction generates a lot of heat, and untimely heat dissipation will lead to high bearing temperature, which will affect the performance and reliability of the motor and even lead to generator failure.

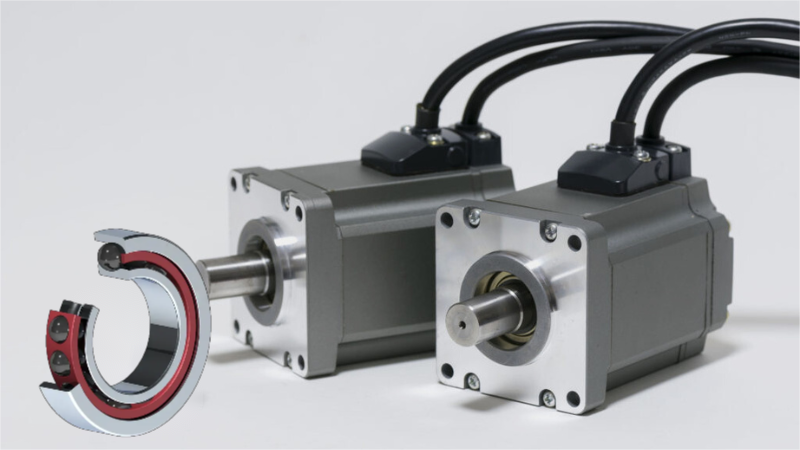

The TFL Solution

-

Material Upgrade: The inner and outer rings of the bearings are made of special high-strength alloy steel, which is precision forged and heat-treated to provide higher hardness and abrasion resistance to withstand greater loads. The rolling body is made of ceramic silicon nitride (Si₃N₄) material, which has the advantages of low density, high hardness, and low coefficient of thermal expansion, effectively reducing the friction and heat generation between the rolling body and the raceway and improving the high-speed performance and service life of the bearings.

- Structure Optimization: The internal structure of the bearing is optimized, and the contact angle and radius of curvature of the raceway are reasonably adjusted, which improves the bearing's load-carrying capacity and rigidity and ensures that the bearing can still maintain stable operating accuracy under complex load conditions. At the same time, the high-precision window cage is adopted, and the laminated phenolic resin material is selected, which has good wear resistance, self-lubrication, and lightweight characteristics and can effectively isolate and guide the rolling bodies, reduce the friction and wear between the rolling bodies, and ensure the even distribution of the rolling bodies in the rolling process and a stable trajectory of the movement.

- Lubrication Improvement: The bearings are equipped with high-speed lubricants specially developed for spindle bearings, and by designing lubrication grooves in the circumferential direction and radial lubrication holes on the outer ring of the bearings, uniform lubrication inside the bearings is realized, which further reduces the friction and heat generation and improves the operating efficiency and reliability of the bearings.

Product Features

- High strength alloy steel

- Higher hardness and wear resistance

- Ceramic materials have the advantages of low density, high hardness, low coefficient of thermal expansion, etc.

- Optimised internal structure of the bearing

- High Precision Window Cage

- Equipped with a high-speed lubricant specially developed for spindle bearings.

Application effects

- Significant Improvement Of Precision: The high precision characteristics of TFL super precision single row angular contact ball bearings make the rotational precision of the servo motor greatly improved, the machining precision and positioning accuracy of the equipment on the workpiece greatly improved, and the scrap rate reduced from 5% to less than 1%, which effectively improves the product quality and strengthens the competitiveness of the customers in the market.

- Dramatic Extension of Life: Through material upgrading and structural optimization, the wear-resistant performance and load-bearing capacity of TFL bearings have been significantly enhanced, and the average service life of the bearings has been extended from 6 months to more than 3 years under the same working conditions, which greatly reduces the number of bearing replacements and equipment downtime and reduces the maintenance costs and production losses. According to the statistics, the annual maintenance cost for customers can save more than $21,000.

- Heat Dissipation Problem Solving: Ceramic rolling bodies and an optimized lubrication system effectively reduce the heat generation of bearings when running at high speeds. Together with good heat dissipation design, the bearing temperature is always kept within a reasonable range, so the performance and reliability of the motor are reliably guaranteed, motor failures due to high temperatures are avoided, and the stability and operating efficiency of the equipment are significantly improved. At the same time, due to the more stable operation of the motor, energy consumption is also reduced, achieving the goal of energy saving and emission reduction for customers.

- Improved Production Efficiency: The high precision and stability of the equipment make the processing process smoother, and the production efficiency has been significantly improved. Taking the production of a certain product as an example, after adopting TFL bearings, the output per unit of time has increased by 30%, which effectively meets the customer’s growing demand for orders and brings considerable economic benefits to the enterprise.

Cost-Savings Breakdown

| UPTIME IMPROVEMEN | $15,000 |

| REDUCED ACQUISITION COST | $6,000 |

| DOCUMENTED COST SAVINGS | $21,000 |

| ANNUALIZED COST SAVINGS | $21,000 |

About TFL BEARINGS

Why is TFL BEARINGS frequently chosen as the specified bearing brand bymajor international companies?

Reliable Operation Starts Here

Contact TFL Bearings for the Best Solutions!

Our efficient global supply chain and inventory management ensure fast response and timely delivery.

We tailor bearing solutions to unique needs. Services include design advice & custom specifications for your specific application.

Competitive prices. Quality bearings meet int'l stds; interchangeable. Reliable, economical alternative. Lower costs, keep performance & value.

Quality products plus reliable full service. Our pro team offers support from selection to after-sales. We aim to be your trusted partner.