Which locking method should you choose for a bearing housing on a shaft?

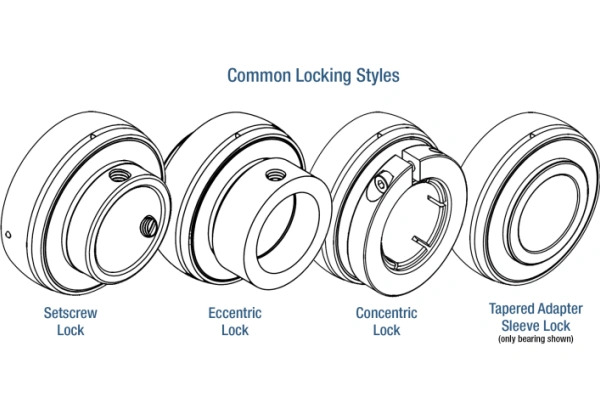

Key decision-factors include: locking type (set-screw, eccentric collar, concentric clamp, adapter sleeve), rotation direction (uni vs bi), speed, and vibration.

As a professional bearings factory from China, we offer mounted bearings (e.g., standard UCP205) with four primary locking technologies: Set Screw, Eccentric Locking Collar, ConCentra Technology, and Adapter Sleeve. Correct selection can significantly extend bearing life by over 30% and reduce maintenance costs by up to 40%.

Core Value of Mounted Bearings

Mounted bearings (Pillow Block Bearings / Housed Bearings) are widely used in conveyors, agricultural machinery, and fans because of their “plug-and-play” characteristic. Their spherical outer ring design effectively compensates for initial misalignment errors caused by housing tilt (up to ±5%), greatly simplifying the installation process and ensuring longevity.

However, if the locking method is incorrectly chosen, the bearing can loosen, slip, or even damage the shaft during operation, negating all its advantages.

Why Locking Method Matters

When a mounted bearing housing is installed on a shaft, a proper locking method is essential to avoid:

- Inner ring sliding on the shaft → wear, groove, even shaft failure.

- Mis-centering of the shaft in the bearing bore → vibration, noise, reduced life.

- High speed or vibration demands greater precision in locking.

Therefore, when selecting a housed bearing unit (such as SN, SNL, UCP series), you must consider shaft size, rotational speed, load, direction, installation environment.

Our TFL advantage:

- Wide model range (bearing inserts + housings) and multiple locking options.

- Custom bore machining and locking sleeves for special conditions (e.g., bi-direction loads).

- We provide engineers to help you select based on rpm, vibration, tolerance.

Detailed Comparison and Selection Advice for 4 Main Locking Methods

Below are the main locking solutions offered by TFL and their suitable scenarios:

| Locking Method | Suitable Rotation Direction | Anti-Vibration/Shock Capability | Suitable Load/Speed | TFL Selection Advantage |

| 1. Set Screw Locking | Constant or Reversing | Lower (General Purpose) | Wide Application Range | Easiest and most cost-effective installation, most common (e.g., UC series) |

| 2. Eccentric Collar Locking | Constant Direction ONLY | Stronger (than Set Screw) | Medium | Strong resistance to vibration, suitable for unidirectional high-speed applications. |

| 3. ConCentra Technology | Constant or Reversing | Extremely Strong (Best for High Vibration) | Heavy Load, High Speed | True concentric locking, eliminates creep corrosion, low noise. |

| 4. Adapter Sleeve Locking | Constant or Reversing | Strong | Heavy Load, High Speed | Reliable fixation and full limiting speed even with lower shaft tolerance. |

Set-Screw Locking

Features: Two or three set screws (often 120° apart) lock inner ring to shaft.

Suitable for: Bi-directional drives, low to moderate speed, low vibration.

Pros:

- Simple installation

- Low cost

Cons:

- Small contact area

- Off-center loading

- Prone to loosening under vibration — can damage shaft.

Tip: Use when speed < ~1000 rpm, load stable, shaft tolerance good; avoid for high speed or heavy vibration.

TFL Bearings’ Advantage: Our setscrew locking bearings feature high-strength setscrews and precisely machined inner rings to ensure secure fastening. For instance, our UCF205 bearing unit, with setscrew locking, is widely used in agricultural machinery and conveying equipment, offering quick installation and reducing downtime. Based on our analysis of industry data, setscrew locking can save up to 30% on installation time in light to medium-load applications compared to more complex locking methods.

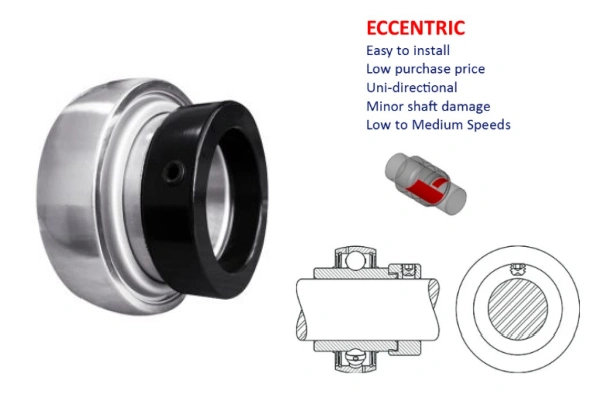

Eccentric Collar Locking

Features: A collar with eccentric lip clamps inner ring when rotated, then fix screw.

Suitable for: Uni-directional rotation, moderate speed, moderate vibration.

Pros:

- Larger contact, better hold than set-screw

- Less shaft damage risk

Cons:

- Not for bi-directional

- At high speed still some off-centering risk

Tip: Good for single-direction machines at e.g. 2000–3000 rpm; if reverse direction or high speed → look further.

TFL Bearings’ Advantage: TFL’s eccentric locking collar bearings offer stronger vibration resistance, especially suitable for unidirectional rotating equipment requiring higher stability. Our UCP207 bearing unit is commonly used in fans and pumps, where its eccentric locking collar design effectively reduces bearing creep under high-speed operation, thereby extending service life. We adhere to stringent manufacturing standards, ensuring a perfect fit between the eccentric locking collar and the shaft, effectively minimizing the risk of bearing loosening.

Concentric Clamp Collar

Features: Locking ring or split clamp around inner ring 360°, ensures shaft concentricity.

Suitable for: High speed (>3000 rpm), where vibration/imbalance are critical concerns.

Pros:

- Superior centering

- Reduced vibration/noise

- Less damage to shaft

Cons:

- Requires tight shaft tolerance

- Vertical shafts or heavy axial load may reduce holding efficacy.

Tip: Choose for high-speed / precision applications (e.g., packaging machines, fans).

TFL Bearings’ Innovation: TFL bearings featuring ConCentra technology can achieve full limiting speeds even with shafts of lower tolerance grades, significantly reducing noise and vibration levels while effectively eliminating fretting corrosion. This is crucial for critical applications such as paper machinery or mining equipment. Our ConCentra technology products have undergone rigorous testing, with their concentricity performance meeting or even exceeding the standards of comparable SKF products, while offering a competitive cost advantage, potentially saving customers up to 15% in procurement costs.

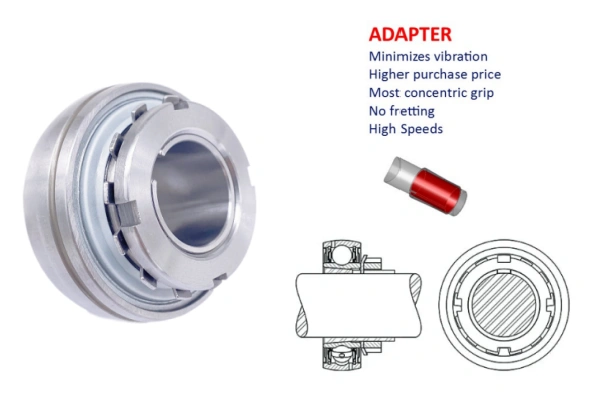

Adapter Sleeve / Tapered Sleeve Locking

Features: Uses a tapered sleeve and lock nut/washers to clamp inner ring to shaft.

Suitable for: Very high speed or heavy load, large tolerance shafts, critical uptime applications.

Pros:

- Largest contact area

- Best centering

- High lifetime potential

Cons:

- More complex installation

- Bigger size, higher cost

Tip: When your machine runs at >5000 rpm, heavy load or shaft tolerance poor — this may be the optimal choice long-term.

TFL Bearings’ Expertise: Our adapter sleeve locking bearings ensure that even with shafts of lower tolerance grades, the bearing’s limiting speed can be achieved and maintained, providing excellent performance for high-speed rotating equipment. This is particularly important in textile machinery and precision machine tools. TFL Bearings’ H200 series adapter sleeves meet or exceed ISO 492 standards for material strength and machining accuracy, ensuring stability and reliability of the bearing during high-speed operation.

How to Decide: Selection Flow

Here’s our step-by-step recommendation (as TFL-factory-style) to pick the right locking method:

- Rotation direction:

- If bi-directional → eliminate eccentric collars.

- If uni-directional → all options open.

- Speed / Vibration / Shock level:

- Low speed (<1000 rpm) & low vibration → set-screw okay.

- Medium speed (1000–3000 rpm), moderate vibration → eccentric or concentric.

- High speed (>3000 rpm), high vibration/precision → concentric or adapter sleeve.

- Shaft tolerance / diameter variation:

- High precision shaft → simpler methods possible.

- Poor tolerance or reuse of shaft → prefer concentric or adapter sleeve.

- Ease vs cost vs downtime risk:

- If budget tight & downtime low-cost → simpler method.

- If downtime costly & maintenance difficult → invest in better locking.

- Contact TFL for custom quote:

- Provide shaft diameter, rpm, direction, load, vibration level.

- We offer custom bore machining, locking sleeve options, and various sealing types.

- We guarantee our units meet ISO standards and compare favorably to global brands.

Case Example: TFL Customized for High-Speed Packaging Machine

Customer: High-speed packaging equipment manufacturer.

- Speed: ~4000 rpm

- Uni-directional rotation

- Shaft tolerance ±0.05 mm

- Medium vibration

Challenge: Using standard set-screw units led to slight vibration and reduced bearing life.

Solution by TFL: Selected same size bearing but with concentric clamp locking to ensure shaft-inner-ring concentricity <0.05 mm.

Result: Customer reported ~25% longer service life, ~30% less vibration/noise, maintenance interval extended from 6 months to 9 months.

Learning: Correct locking method matched to real working condition = lower cost of ownership.

Common Mistakes & How to Avoid

Mistake 1: “All locking methods are equivalent.” → Wrong.

Mistake 2: “Pick lowest cost option (set-screw) always.” → May cost more later in downtime/maintenance.

Mistake 3: “Ignore shaft tolerance.” → Many failures start from undersize or poorly machined shaft.

Avoidance tips:

- Provide your full set of application data to the supplier.

- Ask: direction, rpm, load, vibration, shaft diameter tolerance.

- Ensure supplier (like TFL) offers locking method options, and evaluate lifecycle cost, not just initial cost.

TFL Bearings: Your Bearing Customization Expert

Choosing the right locking method for your mounted bearing housing is critical: it affects installation accuracy, vibration, noise, lifespan and maintenance cost. By understanding the four main locking styles (set-screw, eccentric collar, concentric clamp, adapter sleeve) and matching them to your machine’s specifics (rotation direction, speed, shaft tolerance, vibration), you can optimize performance.

Still unsure about bearing selection? Click the pop-up window in the sidebar to contact our technical experts for a free customized consultation! Let us help you choose the perfect bearing solution for your equipment, improve efficiency, and reduce costs!

At TFL we offer both standard and custom solutions—email info@sdtflbearing.com with your shaft diameter, rpm, direction and bearing housing size. We’ll provide a free selection analysis and detailed quotation to help you select the ideal bearing unit and locking method.