Trusted roller bearing suppliers help businesses run well. Many companies pick suppliers for their good name, wide choices, service, and skill. China is the top bearing maker. It makes 40% of all tapered roller bearings in the world.

This list helps buyers find the best partner fast.

Key Takeaways

- Top tapered roller bearing suppliers like SKF, Timken, NSK, NTN, Schaeffler, JTEKT, Nachi, and TFL sell many good products. People all over the world trust these products.

- Pick a supplier with many products, a good name, and quick service. This helps your business get bearings fast and stops delays.

- Find suppliers with good certificates and lots of experience. This makes sure you get strong and reliable bearings.

- Top suppliers can make custom bearings for special needs. These custom bearings help machines work better in hard places.

- Check each supplier for product choices, worldwide service, and customer help. This helps you find the best partner for your business and helps your company grow.

SKF

Overview

SKF is a top company in the bearing industry. It started in 1907 in Sweden. Sven Wingquist founded it. The company became known for new bearing designs. SKF grew fast and opened offices in many countries. It worked closely with car makers from the start. In 1916, SKF bought its own steel works. This helped them control the quality of their materials. Now, SKF has about 80 factories in 22 countries. It sells products in over 70 countries. More than 15,000 distributors and agents help sell SKF products.

SKF Tapered Roller Bearings

SKF began making tapered roller bearings in the 1920s. People trust these bearings for their accuracy and strength. SKF makes over 20,000 types of bearings. One example is the LM 67010/VU990 tapered roller bearing cone. These bearings are made with care for exact size. They can handle heavy loads from different directions. The bearings use strong steel. Their shape helps spread out the load. SKF’s tapered roller bearings work in many machines. They are used in cars, trucks, and big machines. They also help in building equipment. SKF keeps making better products. Their bearings last longer and work better.

Strengths

- SKF is a well-known and trusted brand.

- It has many factories and sellers for fast delivery.

- The company leads in technology and owns many patents.

- Its bearings can handle heavy loads and high speeds.

- SKF cares about the environment and saves energy.

- It offers services like smart maintenance and digital tools.

SKF uses new ideas and digital tools to help customers work better.

Markets

SKF sells to many industries. These include cars, factories, planes, trains, and energy. The company is strong in Europe, the US, China, and India. SKF’s products meet tough rules for quality. These include ISO/TS 16949 for cars, AS9100 for planes, and IRIS for trains. SKF helps customers in over 130 countries. It does this through a large network of sellers.

Timken

Overview

Timken is a top company in the bearing world. It started in 1899 when Henry Timken made the first tapered roller bearing. Timken is known for making strong and new products. The company works in more than 35 countries. It helps customers all over the world. Timken is famous for careful engineering and good service. Many people trust Timken because it is reliable and knows a lot.

- Timken’s history includes:

- More than 100 years making bearings

- Always working with others to make better products

- Always trying to improve and make customers happy

TIMKEN Tapered Roller Bearings

Timken’s tapered roller bearings can handle both side and up-and-down forces. They work well even in tough places. Timken has the most sizes in the world. Customers can pick single-row, double-row, four-row, or special bearing sets. Some Timken bearings have Duo Face-Plus Seals, flanged cups, or snap-ring cups. The company also makes fuel-saving bearings for trucks and planes. Timken’s engineers help customers find new answers for hard jobs.

Timken’s tapered roller bearings give control and accuracy for important uses.

Strengths

- Timken is trusted for over 100 years of good work

- It sells many products like bearings, gear drives, and belts

- Timken works in more than 35 countries worldwide

- The company spends money to make better products

- Timken gives great service and custom help

- It uses modern factories and makes strong steel

- Timken grows by buying other companies and offering more services

Markets

Timken sells to many industries. Its products are used in planes, cars, building, energy, trains, and big machines. Timken’s bearing sets help trucks, mining, oil, and gas work better. Timken’s products work well in hard places, like fast speeds, heavy weights, and very hot or cold weather. People count on Timken for good results in both normal and special jobs.

NSK

Overview

NSK is the first bearing maker in Japan. It started in 1916. The company has over 100 years of experience and new ideas. NSK works in more than 30 countries. It has 59 places in Japan and 208 sites around the world. These include factories, sales offices, and tech centers. This big network shows NSK cares about quality and safety. NSK helps many industries. It gives customers good products and expert help.

NSK Tapered Roller Bearings

NSK has many types of tapered roller bearings. These bearings are used for different jobs. The lineup has:

- Single-row bearings with cone-shaped tracks for careful load support.

- Double-row bearings that hold up heavy loads from both sides.

- Four-row bearings for hard work like rolling mills, made with Super-TF steel for long life.

- Sealed-clean bearings with spinning end caps, good for axles in rough places.

- Special double-row bearings for tractor gearboxes.

- Low-friction bearings with plastic cages to lower friction in car transmissions.

- Big bearings for gearboxes in wind power and mining.

- Bearings with aligning rings for casting machines in steel plants.

- New materials and tech, like Super-TF steel and WTF technology, make them last longer and resist water.

NSK’s tapered roller bearings help machines need less fixing, last longer, and work well in hard places.

Strengths

- NSK gives full help for making and supplying machine tool parts.

- Its worldwide factories make sure products are high quality.

- NSK knows a lot about friction, oil, and materials, so products last longer.

- The company makes products that are good for the earth and work well.

- NSK helps customers start working fast and solves hard problems.

- Factories everywhere keep strict rules for accuracy and quality.

Markets

NSK works in many places and helps many industries. Main markets are:

- Regions: Asia Pacific (China, Japan, Korea, India, Southeast Asia), North America (US, Canada, Mexico), Europe (Germany, UK, France, Italy, Russia, Turkey), Latin America, Middle East, and Africa.

- Industries: Automotive, heavy machinery, aerospace, medical, mining, construction, railways, wind power, industrial motors, machine tools, and more.

Asia Pacific has about 40% of the world market. North America and Europe come next. Most bearings are used in cars. Heavy machines and planes also use many bearings. NSK’s new ideas and focus on growing in each area help it stay strong in the world market.

NTN

Overview

NTN is one of the biggest bearing makers in the world. It started in 1918. Noboru Niwa, Tomoe Trading Co., and Jiro Nishizono founded it. The NTN brand came out in 1923. In 1939, the Kuwana Works became a main factory. NTN won the Deming Prize for quality in 1954. In the 1950s and 1960s, NTN grew into Europe and North America. NTN Bearing Corporation of America started in 1963. In the 1980s and 1990s, NTN bought Bower™ and BCA™ brands. This made their products more varied. In 2008, NTN bought SNR to get stronger in Europe. Now, NTN has over fifty factories around the world. It is the third biggest bearing maker today.

NTN has a long history and sells bearings all over the world. People trust NTN because it is well known.

NTN Tapered Roller Bearings

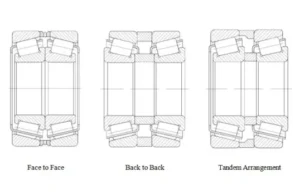

NTN sells many types of tapered roller bearings. They use both the NTN and Bower® brands. The lineup has ISO (metric), inch, and J-metric series. You can get single-row, two-row, double-row, or four-row bearings. Some are back-to-back or face-to-face. Sizes go from metric bores up to 850mm. Imperial bores go up to 1400mm. Special bearings can be as big as 4 meters wide. The bearings use strong alloy steel to last a long time. Some have crowned rollers and special heat treatments. These help in wind energy, trains, and farming. NTN’s Top TRB Stock Guarantee Program gives fast delivery for popular parts.

Strengths

| Strength Aspect | Description |

|---|---|

| Manufacturing Scale | NTN and Bower brands make almost 100 million units each year. |

| Advanced Processes | Case carburization makes the surface hard and the inside tough. |

| Innovative Technology | Crowned rollers help the bearing hold more weight and last longer. |

| Product Range | There are many types and sizes for different jobs. |

| Local Manufacturing | Factories in many countries give quick service everywhere. |

| Brand Quality | NTN products are known for being strong and working well. |

| Application Suitability | Made for hard jobs in cars and big machines. |

| Material and Engineering | Good materials and careful work make them run smoothly. |

Markets

NTN sells bearings to many big industries. These include cars, like wheel hubs and drive trains. Heavy machines, such as those for building, mining, and farming, use them too. Industrial places, like steel plants, forests, and big projects, need them. Special uses are in wind energy and trains. NTN’s bearings help machines like excavators, cranes, tractors, and gearboxes. The company works hard to make new and better products. This helps them meet the needs of tough jobs.

Schaeffler (FAG)

Overview

- In 1883, Friedrich Fischer made a machine that shaped steel balls perfectly round. This started the FAG brand.

- The name FAG means “Fischer’s Automatic Steel Ball Factory.” It became official in 1905.

- Wilhelm and Georg Schaeffler started the Schaeffler Group in 1946. Now, the group owns FAG, INA, and LuK brands.

- Schaeffler is a top company for rolling element bearings. It helps the automotive, aerospace, and industrial markets.

- The company grew by opening new plants in Russia, Thailand, and the USA.

- Schaeffler’s leaders have important jobs, like being president of the World Bearing Association.

- The company grew by selling shares, making new electric axle technology, and buying companies for self-driving cars.

- In 2024, Schaeffler changed to keep up with the world. Its good name stayed strong.

Schaeffler Tapered Roller Bearings

- Single row tapered roller bearings in basic designs

- Matched tapered roller bearings, paired in X, O, or tandem ways

- Integral tapered roller bearings, paired and sealed on one side

These bearings hold up heavy side and straight loads. They come open or sealed and use sheet steel cages. Schaeffler makes them with very exact sizes. They work from -30°C to +120°C. Models like FAG 32310-A and FAG 32313-A show the brand’s focus on being exact and strong.

Strengths

- Schaeffler (FAG) is known for strong and dependable bearing designs.

- The company spends money to make products better.

- Its products include deep groove ball bearings, tapered roller bearings, and needle bearings.

- Customers get help with technical advice and studies for their needs.

- FAG Split Cylindrical Roller Bearings are easy to change, so machines stop for less time.

- Bearings use hard steel for strength and to last longer.

- The product line fits many shaft sizes and can self-align up to ±3 degrees.

- Housings are made from strong ductile iron, with steel choices too.

Schaeffler gives custom bearing solutions for industries that need special designs or quick changes.

Markets

Schaeffler works in 49 countries and has about 170 places. The company built a plant in Russia to help local buyers fast. Big industries are automotive, industrial machinery, aerospace, building equipment, railway, factories, transport, energy, mining, and farming.

| Industry / Region | Description / Key Points |

|---|---|

| Automotive | Makes up a lot of demand, mostly for cars and trucks. |

| Industrial Machinery | Uses bearings in many types of machines. |

| Aerospace | Needs bearings that are exact and dependable. |

| Construction Equipment | Uses bearings in big, heavy machines. |

| Railway | Needs bearings for trains and tracks. |

| Manufacturing | Uses bearings in many different areas. |

| Transportation | Includes cars and other vehicles. |

| Energy | Uses bearings in power machines. |

| Mining | Needs bearings for tough, heavy machines. |

| Agriculture | Uses bearings in farm machines. |

| North America | Has a strong market with good roads and buildings. |

| Europe | Focuses on smart engineering and being green. |

| Asia-Pacific | Grows fast with more factories and industry. |

| Latin America | Gets better with new money and projects. |

JTEKT (Koyo)

Overview

JTEKT Corporation started in 2006 when Koyo Seiko and Toyoda Machine Works joined together. The company mixes bearing technology with machine tool skills. Its main office is in Nagoya, Japan. JTEKT has about 55,000 workers. It works in over 27 countries. The company has factories in Japan, China, Europe, and North America. In 2022, JTEKT changed its brand worldwide. The Koyo name and logo became JTEKT. This helps the company look the same everywhere. It keeps making good products and giving great service.

JTEKT is a top Japanese maker. It competes with big European brands and works with companies like Toyota and Komatsu.

JTEKT Tapered Roller Bearings

JTEKT (Koyo) makes many types of tapered roller bearings. There are single-row, two-row, and four-row bearings. Each bearing has an inner ring, outer ring, cage, and tapered rollers. This design lets them hold both side and straight loads. JTEKT makes metric and inch series. One model is KOYO 32016 JR. The company tries to make bearings smaller, lighter, and better for the earth. These bearings are used in cars, farms, building, steel, wind energy, and machines.

Strengths

- JTEKT is one of the four biggest bearing makers in Japan.

- It has eight large factories in Japan and many sites worldwide.

- JTEKT makes very exact bearings for important jobs like planes, cars, and machines.

- The company spends money on new ideas and uses smart ways to make and check products.

- JTEKT’s strong factories and smart workers make sure products are always good.

Markets

- Key Industries:

- Automotive: wheel bearings, hub units, transmission, engine, and suspension.

- Industrial: factories, mining, building, farming, and energy.

- Heavy machinery: cranes, oil drilling, rolling mills.

- Key Regions:

- North America and Europe: have big factories and industries.

- Asia-Pacific: growing fast, mainly in China and India.

- UAE: is a main export center for the Middle East, Africa, South Asia, Southeast Asia, and South America.

- South America: markets are getting bigger in Brazil and Argentina.

JTEKT (Koyo) has a strong presence around the world. It helps many customers in different places and industries.

Nachi

Overview

- Nachi-Fujikoshi Corp. started in Japan in 1928.

- At first, the company made cutting tools. Later, it began making bearings and other things.

- Nachi is now one of the top five bearing companies in Japan.

- People know Nachi for its careful engineering and products that work well.

- Nachi helps many fields, like cars, machines, and airplanes.

- The company sells to customers in the USA, Europe, Asia, and South America.

- People from many countries say good things about Nachi’s quality and service.

Nachi has been around a long time. Its focus on quality makes it a trusted name for bearings.

Nachi Tapered Roller Bearings

- Nachi makes single-row tapered roller bearings with strong chrome steel (GCR15).

- These bearings are very hard, between 59 and 62 HRC, and have steel cages for extra strength.

- Each bearing can be taken apart. It has an outer ring called a cup and an inner ring with rollers called a cone.

- The design lets the bearing handle big side and straight forces. This makes them good for hard jobs.

- Nachi uses new machines and checks quality carefully. It has ISO9001:2015 certification.

- These bearings are used in cars, trucks, planes, farms, mines, trains, and wind energy.

- Sizes go from small to medium, with outer diameters from 60 to 115mm. Custom sizes can be made.

- About 60% of Nachi’s bearings are sent to other countries, like Italy, Poland, the USA, Mexico, and Brazil.

Strengths

- Nachi controls all steps, from making steel to putting the bearing together.

- The company uses new technology and special steel to make better bearings.

- Nachi’s bearings are strong and run smoothly. They can hold both side and straight loads.

- The steel cages last a long time, and prices are fair for buyers.

- Nachi can make special bearings for different needs.

- TFL Bearings is an official seller. It keeps many Nachi bearings in stock and gives expert help.

- Nachi is known for its many years of experience and focus on making good products.

Nachi makes its own bearings and checks them closely. This means they work well even in tough jobs.

Markets

| Industry | Application Examples |

|---|---|

| Automotive | Transmissions, wheel hubs |

| Aerospace | Aircraft parts |

| Industrial | Machines, gearboxes |

| Agriculture | Tractors, harvesters |

| Construction | Heavy equipment |

| Mining | Conveyors, crushers |

| Rail | Train axles |

| Wind Energy | Turbine gearboxes |

Nachi’s tapered roller bearings are used in many industries all over the world. The company ships many bearings to other countries and has a big network to help customers everywhere.

TFL

Overview

TFL is a trusted supplier in the world bearing market. The company is known for good quality and being reliable. TFL is based in China and sells to over 50 countries. The team works hard to deliver orders fast and answer customers quickly. TFL has many bearing choices for different industries. The company uses new machines and hires skilled workers. TFL wants to help both big and small businesses.

TFL Tapered Roller Bearings

TFL has many types of tapered roller bearings. The products come in regular and special sizes. Customers can pick single-row, double-row, or four-row bearings. Each bearing is made with strong steel to last a long time. TFL checks every bearing to make sure it is correct before sending it out. The company also helps customers pick the right bearing for their machines.

TFL’s tapered roller bearings can hold heavy weights and work well in hard places.

Strengths

- Many sizes and types to choose from

- Orders are handled fast and shipped worldwide

- Quality is checked at every step

- Good prices for big or small orders

- Engineers give technical help when needed

- Custom solutions for special projects

TFL’s team helps customers fix problems fast. The company keeps lots of bearings in stock to ship quickly.

Markets

TFL sells bearings to many kinds of businesses. These include cars, mining, building, farming, and trains. The company ships to Europe, North America, South America, Africa, and Southeast Asia. TFL’s bearings help machines work in factories, on farms, and in transport. Many people pick TFL because the service is good and the products are always high quality.

Selection Criteria

Picking the right supplier is very important for a business. Buyers need to think about a few key things before choosing. Here are the main things to check when picking roller bearing suppliers:

- Product Range

Good suppliers have many kinds and sizes of bearings. This makes it easy for buyers to get the right part for each job. - Reputation

Trusted suppliers have been in the business a long time. They get good feedback from customers and other companies. - Service Quality

Fast help and good support are important. Suppliers who answer fast help businesses avoid waiting. - Experience

Companies with lots of years in the market know how to fix problems. They also know what different industries need. - Certifications and Standards

The best suppliers follow strict quality rules. Look for ISO or other important certificates. - Delivery and Stock

Good suppliers keep products ready and ship on time. This helps machines keep working without long stops.

Tip: Always ask for proof or stories from other customers. These show how the supplier helped other businesses.

Practical Tips for Evaluation:

- Ask for samples to see if the quality is good.

- Compare prices and how fast they deliver.

- Check the supplier’s website for more details.

- Call customer service to see how they help.

- Read reviews and reports online.

Checking these things helps buyers pick the best partner. The right roller bearing suppliers help your business grow and run well.

Comparing Roller Bearing Suppliers

Picking the right roller bearing supplier can be hard. There are many choices, and it can feel confusing. Comparing them side by side makes things clearer. The table below shows important points for each supplier. It lists things like product range, where they sell, and how they help customers.

| Supplier | Product Range | Global Reach | Support & Service | Industry Focus | Custom Solutions |

|---|---|---|---|---|---|

| SKF | Very Broad | 70+ Countries | Advanced, Digital | Automotive, Industrial | Yes |

| Timken | Extensive | 35+ Countries | Engineering Support | Heavy Industry, Rail | Yes |

| NSK | Wide | 30+ Countries | Technical Centers | Automotive, Machinery | Yes |

| NTN | Wide | 50+ Countries | Local Warehousing | Automotive, Energy | Yes |

| Schaeffler (FAG) | Broad | 49 Countries | Technical Consulting | Automotive, Aerospace | Yes |

| JTEKT (Koyo) | Wide | 27+ Countries | Localized Service | Automotive, Heavy | Yes |

| Nachi | Medium to Wide | 40+ Countries | Fast Response | Automotive, Mining | Yes |

| TFL | Wide | 50+ Countries | Fast, Flexible | Industrial, Transport | Yes |

Tip: Buyers should check both the product range and support. Good service helps fix problems fast.

Suppliers with many products can help with different needs. If a company sells in many countries, it can deliver faster. Some suppliers work with only a few industries. Others help many types of businesses. Custom solutions are good when regular bearings do not fit.

This table lets buyers compare suppliers easily. It helps match what a business needs with the right supplier. Looking at these things helps companies pick the best partner for the future.

Choosing a Supplier

Picking the right supplier is important for any business. Companies should use clear steps to find the best match. Here are some easy ways to help buyers choose well:

- Define Business Needs

Write down what types and sizes of bearings you need. Think about the machines and industries you use. - Check Supplier Reputation

Look up each supplier’s past. Read reviews, awards, and what customers say. - Evaluate Product Range

Suppliers with many choices can meet new needs. This helps your business grow. - Test Service Quality

Call customer support. Quick and helpful replies mean good service. - Request Samples or Case Studies

Ask for samples or stories from other buyers. These show how the products work in real life. - Compare Delivery and Stock

Good roller bearing suppliers keep items ready and ship on time. This helps stop long waits. - Look for Custom Bearing Solutions

Some jobs need special designs. Suppliers with custom choices can fix special problems.

Tip: Work with a supplier who knows your industry well. This can mean better prices, faster help, and smart ideas.

Choosing the right supplier helps your business do well for a long time. A trusted partner helps you avoid delays and keeps machines working. Picking carefully now means fewer problems later.

Working with the best roller bearing suppliers helps businesses get good products and expert help. Readers should look at the comparison table and the list of things to check before picking a supplier.

- Look at what each supplier is good at and which markets they serve.

- Compare what kinds of products they have and how good their service is.

What to do next: Reach out to suppliers for prices or ask for samples to see if the quality is good. Picking the right supplier helps your business run well and grow over time.

If you are still unsure which supplier’s tapered roller bearings to use, you can choose TFL. We provide you with fast-responding services and high-quality bearings at reasonable prices. Contact us to get the latest quotation.

FAQ

What industries use tapered roller bearings most often?

Tapered roller bearings are used in many big industries. These include cars, mining, building, trains, and heavy machines. They help vehicles and equipment carry heavy things and go fast.

How can buyers check the quality of a bearing supplier?

Buyers can ask for samples to see the product. They should look at certificates like ISO. Reading what other customers say is helpful. It is good to ask for stories or examples from similar jobs.

Why do businesses choose suppliers with a wide product range?

A wide product range lets companies find the right bearing. They can get all their parts from one place. This saves time and money for the business.

What certifications should a reliable bearing supplier have?

Good suppliers usually have ISO 9001 for quality. Some also have special certificates for cars or planes, like ISO/TS 16949 or AS9100.

How do custom bearing solutions benefit companies?

Custom solutions help companies fix special problems. Suppliers make these bearings for certain machines or hard jobs. This makes the machines work better and last longer.