Thrust roller bearings hold up heavy loads that push in one direction. They are very important in vertical pumps and big machine tool tables. These places need things to be steady and exact. If you pick the wrong bearing or do not take care of it, big problems can happen. These problems include:

- The bearing can break too soon and stop work

- The machine can shake, get loud, and heat up

- Other parts of the machine can get hurt

- Fixing things can cost more and be dangerous

Checking bearings often and putting them in the right way helps everything work well.

Key Takeaways

- Thrust roller bearings hold heavy loads. They keep shafts steady in vertical pumps and machine tool tables. This helps machines run well and last longer.

- Picking the right bearing type and material is important. It depends on the machine’s load and speed. This stops early failures and saves money on repairs.

- Checking bearings often and using the right oil stops damage. It also lowers noise and vibration. This helps bearings last longer.

- Some bearings are made for different load directions and high thrust. These special designs keep machines steady and accurate in hard jobs.

- Taking care of machines and finding problems early keeps them safe. It also helps them work better and stops expensive downtime.

Thrust Roller Bearings Overview

Definition and Function

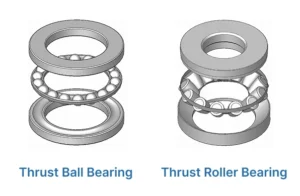

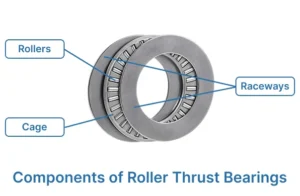

Thrust roller bearings are a type of roller element bearing. They help hold up heavy loads that push along the shaft. Groups like ANSI, ABMA, ISO, and DIN have rules for these bearings. These rules are called standards, such as ABMA Standard 20, ISO 492, and DIN 620. The standards sort bearings by how good and exact they are. They use rating systems like ABEC and RBEC. Each system has five classes. Bigger numbers mean the bearing is more exact. Thrust roller bearings, like cylindrical roller thrust types, use rollers and cages to carry heavy loads. They often work with hard flat surfaces or thrust washers. This design helps them work well in hard jobs, like in vertical pumps and big machine tool tables.

Key Features

Thrust roller bearings are special because of their design and how they work. The table below shows how they are different from other bearings:

| Bearing Type | Rolling Element Shape | Load Capacity and Direction | Special Features |

|---|---|---|---|

| Cylindrical Thrust Roller | Cylindrical rollers | High axial loads only; no radial load capability | Can withstand impact loads |

| Needle Thrust Roller | Needle-shaped rollers | High axial loads in a compact form factor | Suitable for limited radial space |

| Tapered Thrust Roller | Conical rollers | Axial loads in one or both directions; some radial | Pure rolling motion reduces heat and wear |

| Spherical Thrust Roller | Barrel-shaped rollers | Very high axial loads; small to moderate radial | Can handle misalignment |

These bearings use rollers, not balls. The roller shape makes more contact with surfaces. This helps them hold heavier loads. Thrust roller bearings are very exact and steady. They do not wear out or get hot easily. This makes them good for tough places. Engineers pick these bearings when machines need to be strong and exact.

Applications in Vertical Pumps

Load Support

Vertical pumps have to deal with strong forces. These forces push along the shaft. They are called axial load and radial load. Thrust roller bearings help manage these forces. The rollers have a big contact area. This helps them hold up high axial load. In most vertical pumps, the bearing is at the bottom. It takes the main thrust from the pump shaft.

Engineers pick different roller bearings for each pump. For example:

- Tapered roller thrust bearings can handle both big axial and radial load.

- Cylindrical roller thrust bearings work well at high speeds and with heavy loads.

- Spherical roller bearings can hold large downthrusts and fix small shaft problems.

The right bearing design helps the pump work well. It keeps the shaft steady and stops it from moving up or down. This support lowers friction and wear. The pump lasts longer and works better.

Tip: Always pick the bearing type that fits the pump’s load and speed. This helps stop early failure and saves money on repairs.

Alignment and Stability

It is very important to keep the shaft straight in vertical pumps. Thrust roller bearings help keep the shaft steady. They give a strong base and let the shaft spin easily. The still part of the bearing holds the shaft in place. The moving part lets it turn without shaking.

These bearings help with alignment and stability by:

- Keeping the shaft straight and lowering wear.

- Stopping the shaft from moving out of place.

- Sending thrust to the bearing housing to keep the shaft centered.

- Lowering friction so the pump runs quietly and well.

Some pumps use spherical roller bearings because they can self-align. These bearings can fix small mistakes in shaft position. They do not lose strength or life. In pumps with heavy loads, engineers may use tilting pad bearings. These have metal pads that tilt to spread the load. This helps keep things stable and lined up.

Lubrication and cooling are also important. They keep the bearing cool and stop it from wearing out. Springs can help keep the bearing parts touching. This gives steady support when the load changes.

Note: Good alignment and steady support from the bearing stop vibration, noise, and early wear. This makes the pump last longer and work better.

The Importance of Bearing Selection

Picking the right bearing is very important for pump life. If the bearing cannot handle the real thrust, it may break early. For example, one case showed that wrong thrust load math caused many bearing failures in a vertical turbine pump. By checking the real thrust and using a bigger bearing, the pump worked better.

Engineers must think about the pump’s load, speed, and the liquid it moves. The bearing’s material matters too. Some bearings work better with dirty or rough liquids. Others can handle heat or dry starts. The right choice saves energy, cuts repairs, and keeps the pump running longer.

| Bearing Type | Best For | Special Feature |

|---|---|---|

| Tapered roller thrust | Large axial and radial load | Handles combined loads |

| Cylindrical roller thrust | High speed, heavy load | Good for limited space |

| Spherical roller | Large downthrust, misalignment | Self-aligning, stable support |

| Tilting pad | Very high thrust, long life | Even load distribution |

Reminder: Always check what the pump needs and match it with the right bearing type and material. This is very important for safe and good pump work.

Applications in Machine Tool Tables

Precision and Rigidity

Big machine tool tables need to be very exact and strong. These tables are used in vertical lathes and vtl tables. Thrust roller bearings are very important in these machines. They help hold up heavy axial loads. They also keep the rotary tables steady. This steadiness is needed for the machine to cut parts right.

Many vtl tables and vertical lathes use precision tapered cross-roller bearings. These bearings have both axial cylindrical rollers and radial needle rollers. This lets them handle forces from many directions. When preload is set just right, the bearing gets stiffer and can hold more weight. Rotary tables often use thrust crossed roller bearings. These have two rows of rollers that cross each other. The rollers touch the raceways in a line. This gives the table strong tilting stiffness. Preload can be changed to make the table even stiffer and lower runout. This helps the machine work more exactly.

Thrust roller bearings do many things in machine tool tables:

- They hold up big axial loads.

- They make the table stiff so it does not move.

- They help rotary tables in lathes and vtl tables.

- They help the machine stay exact when cutting.

Precision tapered cross-roller bearings are made from case-carburized steel. This steel makes the bearing tough inside and hard on the outside. This helps the bearing last longer and stay steady. It is good for machines that do hard work.

Impact on Machining Quality

How well the bearings work changes how good the machine cuts. Good bearings lower friction and wear. This makes the table move smoothly and keeps it steady. When a machine uses good thrust roller bearings, it stays exact and makes parts that fit well.

Cylindrical roller bearings have low friction and are very stiff. This stops the table from bending when cutting. Double direction angular contact thrust ball bearings help keep spindle shafts in place. This makes vertical lathes and vtl tables more steady. The TSS series machine table uses high-precision thrust cylindrical roller bearings. These bearings hold heavy loads and let the machine cut fast and steady. This means the machine can work on big parts and still cut them well.

Note: Picking the right bearings for vertical lathes and vtl tables helps the machine stay exact, last longer, and make better parts.

Types of Thrust Roller Bearings

Cylindrical Roller

A thrust cylindrical roller bearing uses straight rollers. These rollers help hold up heavy axial loads. The bearing is small and fits in tight spots. The rollers sit in a cage that keeps them apart. This design makes the bearing strong and last a long time. The roller ends are shaped to lower stress and wear. These bearings work best when strong axial support is needed. They do not handle much radial load. You can find them in car gearboxes, motorcycles, and farm machines. The simple design makes it easy to take apart for repairs.

Note: Thrust cylindrical roller bearings are great for jobs with high loads and speeds when space is tight.

Spherical Roller

Spherical roller thrust bearings can handle heavy axial and some radial loads. The rollers are shaped like barrels and can self-align. This means the bearing can adjust if the shaft bends. It also helps if there are small mistakes when putting it in. The self-aligning part lowers vibration and noise. This helps the bearing last longer. These bearings work well in hard jobs like steel mills and wind turbines. They are also used in big machines. They can fix shaft misalignment up to 3 degrees. This keeps machines running well even when stressed.

- Can hold heavy loads because of the big contact area

- Self-aligns to fix shaft problems

- Works well and lasts long in tough places

Tapered and Cross-Roller

Tapered cross-roller bearings mix the good parts of tapered and cross-roller crb designs. Tapered roller bearings use cone-shaped rollers. They can hold big axial loads in one way. If you use them in pairs, they can hold loads both ways. These bearings are used in car wheels and big machines. Cross-roller crb bearings use rollers set at 90 degrees to each other. This lets them hold both radial and two-way axial loads at once. Tapered cross-roller bearings are used in precise machines, CNC rotary tables, and robot joints. They are stiff, small, and spread loads well.

| Aspect | Crossed Cylindrical Roller Bearings | Tapered Roller Bearings |

|---|---|---|

| Roller Shape | Cylindrical, crossed at 90° | Tapered (conical) |

| Axial Load Capacity | Bidirectional | Unidirectional (pairs for both ways) |

| Radial Load Capacity | Strong | Good for medium loads |

| Application | CNC tools, robots, precision machines | Automotive, gearboxes, heavy machines |

Tip: Tapered cross-roller bearings are best for jobs that need high precision, heavy loads, and where space and strength are important.

Load Handling and Arrangements

Normal and High Thrust

Machines like vertical pumps and big tool tables face different thrust forces. Engineers pick bearings based on how much axial load there is and how exact the machine must be. For normal thrust, one angular contact ball bearing or a thrust roller bearing is often enough. These bearings keep the shaft steady and help the machine run right.

When machines have high thrust, engineers use special setups. They sometimes stack two or more bearings together. This makes the bearing hold more load. For very high thrust, spherical roller bearings or hydrodynamic tilting pad bearings are used. These can handle up to five times more than normal thrust. The table below shows some common ways to set up bearings:

| Bearing Type | Load Handling Arrangement | Typical Application / Notes |

|---|---|---|

| Angular Contact Ball Bearing | Single for normal thrust | Used in pumps and motors for moderate thrust. |

| Tandem stack for higher thrust | Increases capacity for heavy-duty use. | |

| Spherical Roller Bearing | Single for very high thrust | Used in deep well pumps; self-aligning for stability. |

| Hydrodynamic (Tilting Pad) | Oil film support for extreme thrust | Used in heavy-duty vertical motors; offers maximum running accuracy. |

Needle roller thrust bearings are good for small spaces with high axial loads. They help lower friction and heat. This makes machines last longer.

Tip: Picking the right bearing setup helps the machine handle both normal and high thrust. It keeps the machine steady and accurate.

Up-Thrust and Special Cases

Some machines get up-thrust or loads that change direction. Regular bearings may not be enough for these cases. Engineers use special setups, like duplex pairs in back-to-back or face-to-face positions. These help control loads that switch direction or make the shaft twist.

Custom bearing groups, like cylindrical roller thrust bearings with more cages, last longer in tough places. Special raceway shapes keep the rollers touching even as they wear down. Using case-hardened steel helps the bearing take hits and not break.

The table below shows some special cases:

| Special Case / Condition | Bearing Type / Arrangement | Description / Purpose |

|---|---|---|

| Reversing axial loads | Duplex pairs (back-to-back or face-to-face) | Handle loads in both directions. |

| Heavy combined radial and thrust loads | Duplex pairs with floating bearings | Share loads between bearings for better performance. |

| Temperature changes | Fixed and floating bearing arrangement | Allows for expansion without stress. |

| Custom features | Preloading, special materials, lubricants | Improve stiffness and accuracy for unique needs. |

Note: Special bearing setups help machines deal with up-thrust, twisting, and changing loads. They keep the machine working well and lasting longer.

Maintenance and Issues

Oil Leaks

Oil leaks in thrust roller bearings can mean bigger problems. Sometimes, stand tubes are loose or the oil tank is too full. Water from condensation can also get in and cause leaks. Dirt or cleaning chemicals can make the oil foam. This foam can push oil out of the bearing housing. If the surface is rough or parts are not lined up, the oil film can break. This makes leaks more likely.

To stop oil leaks, maintenance teams should:

- Look for cracks or loose parts where the shaft meets the stand tube.

- Make sure the stand tube and oil sight glass are tight.

- Use clean oil and keep the area free of dirt.

- Fix cracks with special glue or change broken parts.

- Put in oil sump heaters in wet places to stop water from forming.

- Add anti-foam chemicals if the oil still foams after changing it.

Tip: Grooves and holes in the bearing mount help oil go back to the tank. This lowers the chance of leaks.

Inspection and Prevention

Checking thrust roller bearings often helps them last longer. Teams should not just follow a set schedule. They should pick how often to check based on speed, load, oil, and where the machine is. The main steps are:

- Look for wear, damage, or strange noises.

- Use sensors to watch the bearing’s heat and shaking.

- Oil the bearings the way the maker says.

- Change bearings if they are worn or broken.

The table below shows the main things to check:

| Inspection Task | Purpose |

|---|---|

| Temperature monitoring | Find overheating early |

| Vibration analysis | Spot misalignment or damage |

| Oil condition check | Stop oil problems |

| Visual inspection | Find cracks or leaks |

Troubleshooting

When there are problems, a step-by-step plan helps find the cause. Teams should:

- Check other parts for pinching or if they are not lined up.

- Use a dial indicator to measure crankshaft endplay.

- Use tools like vibration checks and heat cameras.

- Write down what they find and look for patterns.

- Ask experts for help and use the 5-Whys method to find the real cause.

- Teach workers and share fixes to stop problems from coming back.

Note: Finding problems early and working together keeps machines safe and running longer.

Picking the right thrust roller bearing helps machines work well and last longer. Checking bearings often and taking care of them stops damage and keeps things running. It is important to think about the kind of load, where the machine works, and the shape of the bearing. These things help the bearing stay strong and do a good job.

- Checking bearings and using the right oil makes machines better and stops long breaks.

- Talking to experts helps engineers pick the best bearing for each job.

If you need help or want good bearings, TFL Bearings can give you advice and support for any project.

FAQ

What makes thrust roller bearings suitable for vertical pumps?

Thrust roller bearings hold up heavy axial loads. They keep the shaft steady in vertical pumps. Their design helps pumps work well and last longer. Engineers pick them because they are strong. They also work well in hard jobs.

How do thrust roller bearings improve machining in lathes?

Thrust roller bearings give lathes strong and steady support. They help the table stay still when cutting parts. This makes the machine cut better and last longer. Good support means better parts and longer use.

Can thrust roller bearings handle both axial and radial loads?

Some thrust roller bearings can take both axial and radial loads. Tapered and spherical types can do this job. This makes them good for machines with many forces. Big lathes and vertical pumps use these bearings.

How often should maintenance teams inspect thrust roller bearings?

Teams should check bearings based on speed, load, and where they work. Regular checks for wear, noise, and oil help stop problems. Using sensors for heat and shaking finds trouble early.

What signs show a thrust roller bearing needs replacement?

Look for strange noise, more shaking, oil leaks, or worn parts. If a bearing in a lathe or pump has these signs, change it soon. This stops bigger problems with the machine.