Thrust bearings and washers help machines work better in tough places. Machines with both can last up to 50% longer. They can also go 25% faster and hold 30% more weight. These parts lower friction and wear, so things run smoother. Many industries use them, like cars, big machines, and tools. They help make machines more reliable and efficient.

Key Takeaways

- Thrust bearings and washers lower friction and wear. They help machines run better and last up to 50% longer.

- Using thrust bearings and washers together spreads out force. This stops the shaft from moving. It also makes machines faster by up to 25%.

- These parts let machines hold 10-30% more weight. Machines can carry heavier loads safely and work better.

- Choosing, installing, and caring for thrust bearings and washers is important. This keeps machines working well and stops expensive repairs.

- Thrust bearings and washers are used in many fields. They are found in cars, big machines, and machine tools. They help equipment stay quiet, cool, and strong.

Thrust Bearings and Washers Basics

Thrust Bearings Overview

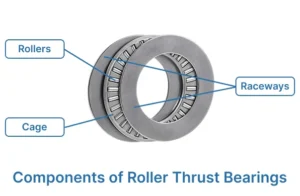

Thrust bearings help hold up forces that push along the shaft. These forces move in the same direction as the shaft. Radial bearings handle forces from the side. Thrust bearings are made to lower friction and stop parts from wearing out fast. This helps machines work better and go faster. The main parts are the bearing housing and rolling pieces like balls or rollers. Good alignment and preload make the bearing stiffer and more accurate. Grease or oil mist helps keep friction low and makes the bearing last longer.

| Feature/Principle | Description |

|---|---|

| Axial Load Handling | Holds forces that go along the shaft with little friction. |

| Load Distribution | Spreads the force out to stop wear and keep things steady. |

| Bearing Geometry | The shape and size change how much load it can hold. |

| Material Selection | Uses strong materials like steel, ceramics, bronze, or polymers for different needs. |

| Types of Thrust Bearings | There are rolling element and fluid film types. |

| Advanced Types | Hydrostatic and magnetic thrust bearings do not touch to hold loads. |

| Lubrication Methods | Grease, oil mist, or pressurized oil help stop friction and wear. |

| Heat Dissipation | Oil flow and cooling keep the bearing from getting too hot. |

| Load Capacity Considerations | Shape, material, oil, and design change how much load it can take. |

| Preload and Alignment | Preload takes out extra space; alignment stops uneven wear. |

Thrust Washers Role

Thrust washers are flat and smooth. They help hold up forces along the shaft and lower friction between moving parts. Makers use strong materials like case-hardened steel, bronze, stainless steel, or special composites. ISO 6525:2018 is a rule that makes sure washers are the right size and shape. Heat treatment makes washers harder and helps them last longer. Engineers pick washers based on how much load, speed, and heat they need to handle.

Note: Thrust washers must be very flat and smooth to work well.

Combined Use

Using thrust bearings and washers together works better than using just one. Washers give a steady surface for the rolling parts. This helps spread out the load and lets things turn smoothly. The combo stops the shaft from moving, lowers wear, and keeps other parts safe. To install, put the housing washer first, then the bearing, then the shaft washer. Oil or grease is still needed to keep things cool and make them last longer. Together, thrust bearings and washers help machines work better and last longer.

- Stops the shaft from moving along its axis

- Lowers friction and wear

- Spreads out the load

- Makes machines faster and last longer

Performance Benefits

Increased Load Capacity

Thrust bearings and washers help machines hold more weight on the shaft. Their strong steel base keeps them from bending or breaking. The layers include steel, bronze, and a polymer sliding surface. These layers spread out the force and help move heat away. This keeps the washer in good shape. Machines with these parts can carry 10-30% more weight than those without.

- The steel layer gives support and keeps the washer stiff.

- The bronze layer connects the parts and holds oil.

- The polymer surface cuts down friction and keeps grease in small spots.

These parts work together to stop metal pieces from touching each other. This lowers the chance of damage and lets machines carry more weight safely.

Extended Service Life

Machines last longer when they use thrust bearings and washers. The special polymer layer, made from POM or PTFE, fights wear and keeps friction low. Small indents in the polymer hold grease, so the surface stays slick even when starting or stopping. The bronze layer inside the washer holds oil or grease to protect the bearing.

Note: Machines with thrust bearings and washers often last 20-50% longer. This means less time fixing and fewer repairs.

The layers also help move heat away from where the parts touch. Less heat means less damage to the parts. The self-lubricating materials keep things smooth and quiet, even if there is not much oil.

Higher Speed

Thrust bearings and washers let machines run faster without getting too hot or wearing out fast. The polymer layer has low friction, so parts slide easily. The bronze and steel layers help move heat away, keeping things cool at high speeds.

Machines with these parts can go 15-25% faster than those with only plain washers or none at all. Lower friction and better heat control mean the parts do not get too hot, even at top speed.

- Grease stays in place during fast movement because of the indents.

- The layers stop metal parts from touching, so there is less noise and shaking.

- The design helps machines stay steady at higher speeds.

These benefits make thrust bearings and washers a good choice for people who want machines to go faster, last longer, and carry more weight.

Mechanisms Explained

Load Distribution

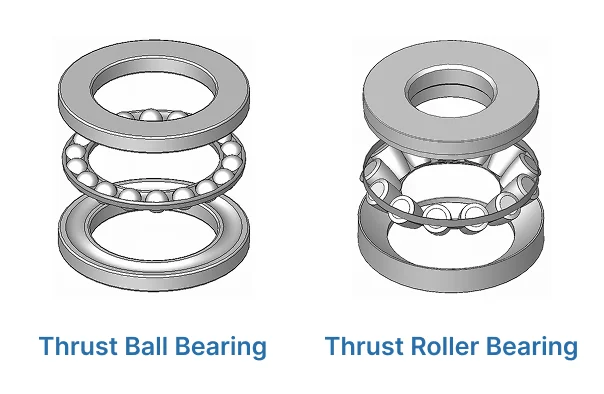

Thrust bearings and washers help spread out the force on the shaft. Thrust ball bearings have balls that line up with the shaft. These balls move the force from one washer to the next. This setup lets the bearing hold big forces without bending. Tapered roller bearings use their shape to move force along slanted sides. This design spreads the force over a bigger area. It lowers stress on any one spot. Good load spreading keeps the bearing from wearing out fast. It helps machines last longer.

Different bearings handle force in their own way. Thrust ball bearings use point contact. This works well for light loads and fast speeds. Double-direction thrust bearings have two sets of balls. They can hold force from both sides. Combined needle roller bearings have needle rollers and an axial part. This design lets them hold side and end forces in small spaces. The line contact from needle rollers spreads the force better. It gives higher load capacity.

| Bearing Type | Load Direction Supported | Rolling Element & Contact Type | Load Distribution Features | Typical Uses |

|---|---|---|---|---|

| Thrust Ball Bearings | Axial (one direction) | Balls; point contact | Good for high speed, lighter axial loads | Pumps, motors |

| Double-Direction Thrust Bearings | Axial (both directions) | Two sets of balls; point contact | Handles changing load directions | Machine tools, cranes |

| Combined Needle Roller Bearings | Radial and axial | Needle rollers (line contact) + axial part | High load capacity in small space, spreads load well | Gearboxes, compact assemblies |

Spreading the force evenly is important for long life. Thrust bearings and washers help keep the load even. This lowers wear and keeps machines working well.

Friction Reduction

Friction makes parts wear out and wastes energy. Thrust bearings and washers use smart designs to lower friction. Small dimples or grooves on the surface can cut friction by up to 30%. These textures help oil spread out and stop too much rubbing. Engineers use special models to pick the best patterns.

- Textures on thrust bearings and washers lower friction and wear.

- Dimple layouts help oil spread and lower friction.

- Tests show textured surfaces last longer and run smoother.

- Coatings, polymer layers, and solid lubricants also help.

- Double washer setups and grooved washers lower friction in tough jobs.

Thrust washers in gear systems often slide metal on metal. This can waste power and cause wear. Nickel coating or a polymer layer can help stop this. Good oil and smart design keep friction low, even when oil is hard to reach.

Heat Management

Machines make heat when parts move and rub. Too much heat can hurt bearings and washers. Thrust bearings and washers use special materials to move heat away. Steel and bronze layers in washers carry heat from the surface. Polymer layers do not get hot as fast. They help keep the surface cool.

Oil or grease in the bearing helps carry heat out. Some designs use grooves or holes for better oil flow. This keeps the bearing from getting too hot, even at high speeds. Good heat control means less damage and longer life for the bearing.

Tip: Always check that the bearing has enough oil or grease. This helps control heat and keeps the bearing working well.

Thrust bearings and washers work together to handle heavy loads, lower friction, and manage heat. Their smart design and good materials help machines run faster, last longer, and stay safe.

Applications

Automotive

Cars use thrust bearings in many important places. Engineers put them behind torque converters in automatic transmissions. They also use them as crankshaft thrust bearings in engines. These parts help control forces that push along the shaft during gear shifts and engine work. Mechanics check crankshaft thrust clearance with a dial indicator when fixing engines. Good assembly, with the right oil and careful tightening, helps bearings last longer. New materials like low-friction plastics and composites make bearings work better. These changes let bearings hold more force and need less oil. Car technicians also make bearings last by using bigger cooler lines and adding extra coolers. This lowers pressure inside and keeps bearings safe. These steps help cars last longer and avoid big repair bills.

Heavy Machinery

Big machines like cranes and mining tools need thrust bearings for heavy loads. Crane turrets use these bearings to hold weight and turn all the way around. Construction and mining machines, pumps, compressors, and boats also use them because they are strong. Oil inside the bearings helps move heat away and makes them quieter. Operators spend less on repairs and get better work because the bearings do not rust and need less oil. Companies that use better bearings have fewer breakdowns and save money. For example, one mining company had 40% fewer failures and saved $200,000 each year after switching to better bearings.

- Stronger and better at handling heat

- Quieter and cheaper to fix

- Work better and do not rust easily

Machine Tools

Machine tools like transmissions, gear sets, and motors need to be lined up just right and be very stiff. Thrust bearings in these tools lower friction and keep the shaft in the right place. This makes the tools work better and last longer. Many bearings can be taken apart and swapped, so fixing them is easier. In tough places, like big machine transmissions, these bearings keep out dirt and hold oil. Special designs, like oil grooves and bigger bearing areas, help them hold more weight and stay cool. These upgrades are important for turbines, compressors, and other spinning machines where being reliable and cool is very important.

Tip: Check bearings often and use the right oil to keep them working well and make them last longer.

Implementation Guide

Selection Tips

Picking the right bearing and washer starts with knowing the job. Engineers need to think about the kind of load and which way it pushes. Some loads go along the shaft, and some push from the side too. Tapered roller bearings are good for car wheels. Spherical roller thrust bearings work best in big machines. The type of oil or grease used is important because it helps stop friction and wear. Small machines may not have much space, so size matters. Cost and how long the parts will last should be balanced for the best deal. Other things like speed, heat, and dirt also help pick the right part.

When picking washers, the material is very important. Bronze is strong and good for heavy jobs. Steel lasts a long time but can rust. Plastic does not rust and is light. Think about how much weight the washer must hold, its size, and if it needs to handle heat or low friction.

Installation Steps

Putting in bearings the right way helps them last longer. Here are the steps:

- Find out if the bearing uses separate washers or one piece.

- Clean the area and check that nothing is broken.

- If using separate washers, put them in the housing and cap.

- The flat side of the washer goes against the housing. The grooved side faces the spinning part to help oil spread.

- Put a thin layer of oil or grease on the washer.

- Line up the shaft and slide the washer into place.

- Use the right tools to press the washer and bearing in. Make sure the tabs fit in the grooves.

- Check that all parts are even and in the right spot before finishing.

Tip: Always make sure things are lined up and have enough space. This stops stress and keeps things from getting too hot.

Maintenance Advice

Taking care of bearings and washers helps them last longer. Check them often for damage, rust, or strange sounds. Use the right oil or grease and add it when needed. Keep the area clean and closed off to stop dirt from getting in. Handle and store the parts carefully so they do not get hurt. Watch the heat and shaking while the machine runs. Use special tools to check for problems early.

Some mistakes are not lining things up, using the wrong oil, or skipping checks. Avoid these by following the maker’s rules, using the right tools, and checking sizes. Bronze washers do not need oil as often because they can oil themselves, but you still need to check them.

Thrust bearings and washers help machines last longer and go faster. They also let machines carry more weight. The table below shows how different washers handle load, heat, and friction:

| Property | Steel-Backed PTFE/POM Washers | Bronze-Graphite Washers |

|---|---|---|

| Load Capacity | Moderate to high | High |

| Temperature Range | -200°C to +260°C (PTFE) | Up to +400°C |

| Corrosion Resistance | Excellent | Moderate |

| Friction Coefficient | Ultra-low | Low to moderate |

| Maintenance | Self-lubricating | Occasional lubrication |

Many companies have seen real improvements:

- One big company saved 20% on costs and shipped faster.

- Better quality and smooth running made products more reliable.

Engineers can make machines work better by picking the right thrust bearings and washers. If you need help, contact us, TFL Bearings can help you choose the best one.

FAQ

What is the main purpose of a thrust bearing?

A thrust bearing holds up forces that push along a shaft. It helps cut down friction and stops parts from wearing out fast. This part lets machines work better and last longer.

How do thrust washers improve bearing performance?

Thrust washers give bearings a flat, smooth place to move. They help spread out the force so it is even. This means less friction, less damage, and a longer life for both the washer and the bearing.

Can thrust bearings and washers handle high temperatures?

Yes, many thrust bearings and washers are made from steel, bronze, or PTFE. These materials can take a lot of heat and still work well. Always check what the material can handle before using it.

How often should maintenance checks occur?

Experts say to check bearings and washers every time you service the machine. Regular checks help you find wear, noise, or heat problems early. This stops big breakdowns and helps the equipment last longer.