Introduction

Ball bearings are critical components in mechanical engineering, serving as essential elements in systems that require controlled motion, reduced friction, and stable load support. Their role extends across a wide range of industries, including automotive, aerospace, heavy machinery, electronics, and precision equipment manufacturing.

SDTFL Bearing specializes in the production of high precision ball bearings designed to deliver reliable performance and long operational life. Through advanced materials, strict production control, and engineered designs, these bearings support the demanding requirements of modern industrial environments.

Definition and Function of Ball Bearings

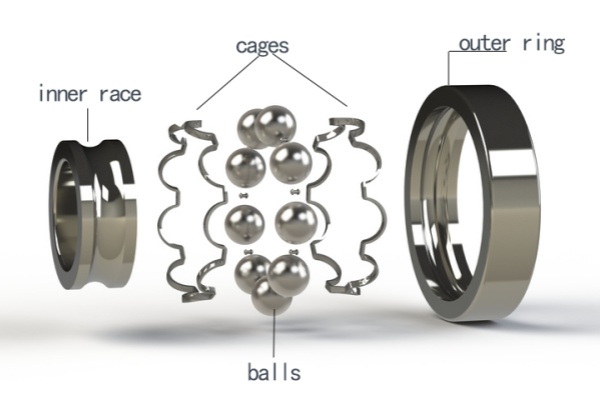

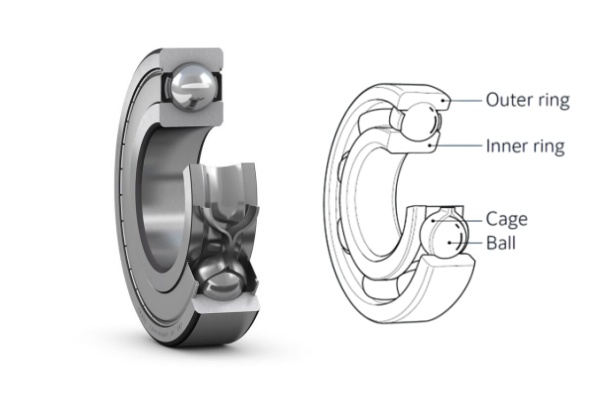

Ball bearings consist of an inner ring, outer ring, cage, and spherical rolling elements. The rolling action of the balls significantly reduces friction between moving parts, enabling smooth and efficient rotational or linear motion.

These bearings support radial loads, axial loads, or a combination of both, depending on their design. The precision of their construction allows machinery to achieve optimal performance with reduced energy consumption, minimal vibration, and consistent operational stability.

Key Advantages of Ball Bearings

Ball bearings provide several technical advantages essential to industrial operations.

Efficient Motion Control

The rolling mechanism reduces friction, providing consistent rotational movement and improving overall machine efficiency.

Precision and Stability

Manufactured with strict tolerances, ball bearings offer minimal vibration, controlled movement, and high accuracy even at elevated speeds.

Durability and Wear Resistance

High grade materials and advanced lubrication solutions extend service life and ensure stable performance over long periods.

Adaptability Across Applications

Ball bearings are produced in multiple sizes, configurations, and material options to meet different engineering requirements.

Reliable Load Distribution

Depending on their structure, ball bearings can effectively support radial and axial forces, contributing to reliable system performance.

Types of Ball Bearings Manufactured by SDTFL Bearing

SDTFL Bearing offers various categories of ball bearings, each designed for specific operational requirements and industrial conditions.

1. Deep Groove Ball Bearings

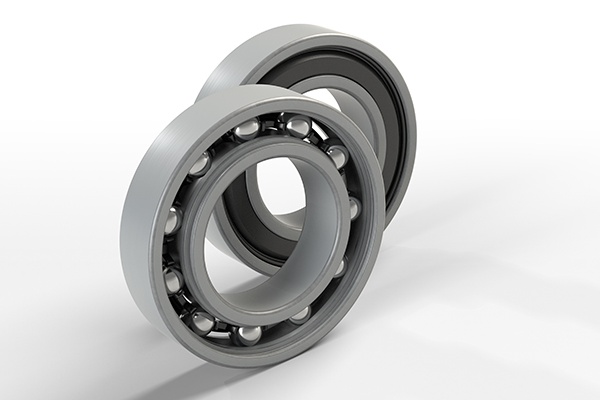

Deep groove ball bearings are widely used due to their simple structure and versatile load carrying capability. Their deep raceway design supports primarily radial loads while also handling moderate axial forces.

Typical Applications

Electric motors

Industrial fans

Pumps and compressors

Power tools

General machinery

Their low noise, low friction, and high speed capability make them suitable for both industrial and commercial equipment.

2. Angular Contact Ball Bearings

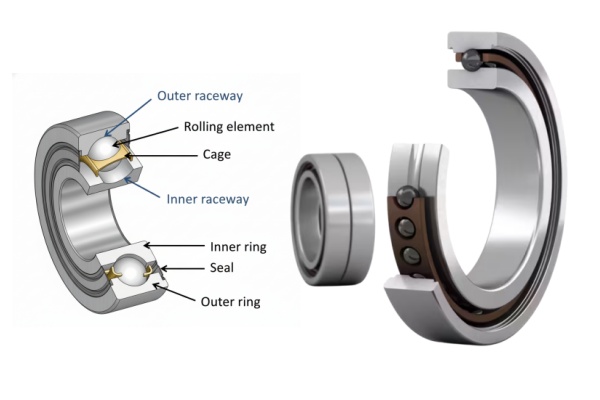

Angular contact ball bearings feature raceways positioned at a defined angle, allowing them to support significant axial loads in one direction in addition to radial loads. Their design offers increased rigidity and stability at high speeds.

Typical Applications

Machine tool spindles

Automotive components

Precision mechanical systems

High speed compressors

Industrial pumps

These bearings are essential in environments where accuracy and load stability are necessary.

3. Miniature Ball Bearings

Miniature ball bearings are designed for compact systems that require precise, smooth movement within limited spaces.

Typical Applications

Robotics

Medical instruments

Micro motors

Optical equipment

Electronic devices

Despite their small size, miniature bearings maintain high performance standards, ensuring reliability in advanced technological systems.

4. Stainless Steel Ball Bearings

Stainless steel bearings are engineered for environments where corrosion resistance, temperature stability, and material cleanliness are critical. They maintain structural integrity under harsh environmental conditions.

Typical Applications

Food processing equipment

Pharmaceutical machinery

Marine applications

Chemical handling systems

These bearings deliver long term performance in environments where traditional bearing materials are unsuitable.

5. High Speed Precision Bearings

High speed precision bearings are developed for applications requiring uniform rotation, low heat generation, and superior accuracy under extreme speeds.

Typical Applications

CNC machine spindles

Turbomachinery

High speed industrial blowers

Precision instrumentation

Their advanced cage structures and optimized materials ensure stable operation during continuous high speed use.

Material Selection and Engineering Standards

The materials used in ball bearing construction play a significant role in determining performance and lifetime. SDTFL utilizes materials selected for strength, fatigue resistance, and reliability.

Bearing Steel

Offers high durability, resistance to wear, and long fatigue life for general industrial applications.

Stainless Steel

Provides corrosion resistance and improved stability in environments with moisture or chemicals.

Ceramic Balls

Used in specific high speed bearings to reduce weight, friction, and heat generation.

Cage Materials

Brass, stainless steel, and engineered polymers are chosen based on operational speed, lubrication, and thermal requirements.

Manufacturing Quality Control

SDTFL Bearing implements rigorous quality control procedures at every stage of production. These measures ensure that every bearing meets international standards for performance and reliability.

Quality Control Measures

Dimensional accuracy inspections

Surface finish analysis

Vibration and noise testing

Heat treatment validation

Hardness testing

Lubrication consistency evaluation

These steps ensure that each bearing provides consistent performance in demanding environments.

Industrial Applications of Ball Bearings

Ball bearings are used across numerous industries due to their mechanical advantages and reliability.

Automotive Sector

Bearings support engines, transmissions, alternators, and wheel systems, ensuring optimized performance and durability.

Industrial Machinery

Conveyor systems, pumps, compressors, and machine tools rely on ball bearings for efficient and stable motion.

Electronics and Appliances

Fans, electric motors, and household appliances require precision bearings for noise control and smooth operation.

Aerospace and Defense

Navigation systems, turbines, and mechanical components depend on high durability bearings capable of withstanding extreme conditions.

Medical and Laboratory Equipment

Diagnostic devices and surgical tools require low noise, high precision bearings for accurate and stable performance.

Selecting the Appropriate Bearing

The performance of a bearing depends on selecting the correct type for the intended application. Important considerations include:

Required load type and magnitude

Rotational speed

Temperature and environmental conditions

Material compatibility

Space constraints

Lubrication requirements

Installation method

SDTFL provides technical guidance to assist customers in selecting bearings that match their operational conditions.

Maintenance Guidelines

Proper maintenance is necessary for extending bearing lifespan and ensuring reliable performance.

Recommended practices include:

Regular lubrication

Protection from dust and contaminants

Avoiding misalignment during installation

Monitoring temperature and vibration

Periodic inspection for wear

Following these guidelines reduces the likelihood of premature bearing failure.

Conclusion

Ball bearings are fundamental components in mechanical systems, enabling efficient motion, controlled load distribution, and reliable long term performance. SDTFL Bearing provides high precision ball bearings engineered for industrial applications requiring durability, accuracy, and operational stability. Through advanced materials, strict production processes, and engineering expertise, SDTFL continues to deliver bearing solutions that support modern industry requirements.

Do not let equipment downtime or inefficiency hold your business back. Let us help you select the perfect solution to optimize your mechanical systems.

Enhance Your Operational Efficiency Today

Ready to secure high-performance bearings for your next project? Reach out to us now to consult with our engineering team or to request a detailed price list.

- Send us an Inquiry: info@sdtflbearing.com

- Speak to an Expert: +86 15806631151

For immediate assistance, simply fill out the contact form on the sidebar, and one of our specialists will respond promptly.