You use tapered roller bearings to help heavy machines work well and stay safe. Good Tapered Roller Bearings pairing spreads the load evenly and stops early breakdowns. If you put these bearings in the right way, you lower shaking, stop too much heat, and make them last longer. Always do what the maker says and pick the right oil or grease. Careful handling and exact adjustment keep both machines and people safe.

Key Takeaways

- Pair tapered roller bearings the right way to share loads. This helps stop too much heat and makes machines last longer.

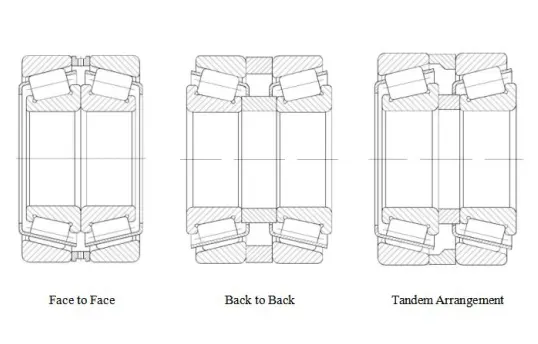

- Pick the best bearing setup for your machine. You can use back-to-back, face-to-face, or tandem. Choose based on how much load and alignment your machine needs.

- Change clearance and preload with care when you install bearings. Turn the bearings as you do this. This helps stop early damage or noise.

- Keep all parts clean and use the right tools. This helps you mount and line up the bearings well so they work smoothly.

- Check and oil the bearings often. Follow what the maker says. This stops problems and keeps machines working well.

Fundamentals of Tapered Roller Bearings

Structure and Components

It is important to know the main parts of tapered roller bearings before you put them together or use them in pairs. Each part helps the bearing work well and last longer. The main parts are:

- Inner ring: This goes on the shaft and holds the rollers.

- Outer ring: This gives support and holds the bearing in place.

- Tapered rollers: These are between the rings and carry the weight.

- Cage or retainer: This keeps the rollers apart so they do not touch.

Makers use strong alloy steels like chrome steel or bearing steel for these parts. These steels make the bearing tough, hard, and able to last a long time. They help the bearing handle heavy loads and hard jobs.

The special shape of the rollers and raceways lets the bearing take both sideways and up-and-down forces at once. This shape spreads the force along the slanted parts. It helps the bearing last longer and work better.

Limitations of a Single Bearing

Using just one tapered roller bearing has some limits. You need to know these so your machines do not have problems.

- One bearing has a top speed. If it spins too fast, it can get too hot or wear out.

- It does not work well if it is not lined up right. Even a small tilt can cause uneven force and early damage.

- Single row tapered roller bearings are open. You must add seals to keep dirt out and keep grease in.

- Lubrication is very important. Without the right oil or grease, the bearing will not last long.

- You often need two bearings together to hold loads from both sides and to fix misalignment.

Tip: Always check the speed and alignment limits before you pick a single bearing for your machine.

You can see how much more weight paired bearings can hold compared to just one:

| Bearing Configuration | Axial Load Support | Radial Load Support | Load Rating Multipliers Compared to Single Bearing |

|---|---|---|---|

| Single Tapered Roller Bearing | Axial load in one direction | High radial load | Baseline (1×) |

| Matched Pair (O or X arrangement) | Axial loads in both directions | Higher radial loads | Dynamic Load Rating (Cr): 1.715× single bearing |

| Static Load Rating (C0r): 2× single bearing | |||

| Fatigue Limit Load (Cur): 2× single bearing | |||

| Tandem Pair | Axial load in one direction | Supports axial load only one direction | N/A |

| Integral Paired Bearings (O arrangement) | Axial loads in both directions | Radial loads supported | Ready-to-fit, sealed, greased, no axial clearance adjustment needed |

Basic Principles of Pairing

Pairing tapered roller bearings helps you control how much the shaft moves back and forth or how tightly the rollers press together. You must set this just right to make the bearings last and work well. Here are the main things to remember:

- Pair bearings to control shaft movement or tightness. This changes how long the bearing lasts and how stiff it feels.

- “Setting” means how much the shaft can move or how tight the parts are.

- There are three main ways to set them: some movement, no movement but more tightness, or just touching.

- Turn the bearings while you adjust them. This helps the rollers sit right and makes things run smooth.

- Try to have almost no shaft movement for most jobs. Some machines need a little tightness for extra strength.

- Do not make them too tight. Too much pressure can make the bearing break early from heat or not enough grease.

- Setting by hand takes skill. You tighten the nut while turning, then loosen it a bit to get the right feel.

- For better control, use preset bearing sets with special spacers. This makes the setting more exact.

- Always keep everything clean and use the right way to put them in. Dirt or bad setup can ruin the bearing.

If you follow these steps, you get the best from tapered roller bearings pairing. You help the bearings hold more weight, last longer, and keep your machines safe and strong.

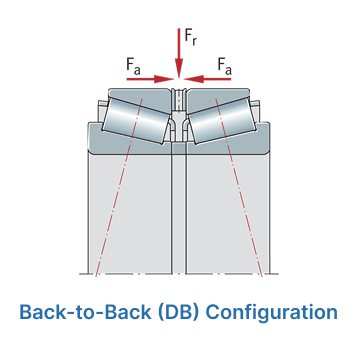

Back-to-Back (DB) Configuration

Characteristics and Applications

In the back-to-back (DB) configuration, the wide sides of the outer rings face each other. This setup changes how the bearings handle force and movement. Here are some important things about it:

- The pressure lines from each bearing meet inside the assembly. This helps share the load and makes the setup stronger.

- This setup gives the highest moment stiffness and rigidity. The bearings can stop tilting and bending better than other setups.

- It has great thermal stability. If the shaft gets hot and grows, the preload on the bearings goes down. This helps stop damage.

- You can use this setup in machines that need to go fast and stay strong, like spindles or precision tools.

You often see the back-to-back setup in heavy-duty machines, high-speed spindles, and equipment that must stay steady when loads change.

Advantages and Disadvantages

There are many good things about using the back-to-back (DB) configuration for your tapered roller bearings:

- It can handle both axial and radial loads in both directions.

- This setup makes the system more rigid and stops tilting, so it stays stable.

- The space between the load centers gets bigger. This spreads out the force and lowers stress on each bearing.

- It is better at handling small shifts in the shaft or housing. The bearings keep working well even if things move a little.

- Heat leaves the bearings more easily, which helps them last longer.

- The load capacity goes up, so this setup is great for heavy-duty jobs.

Tip: Pick the back-to-back (DB) configuration if you need high precision, strong support, and long-lasting performance in tough places.

But there are some downsides too. This setup can take up more room in your machine. You may need to adjust it carefully to get the preload just right. If you do not set it right, you might get early wear or noise.

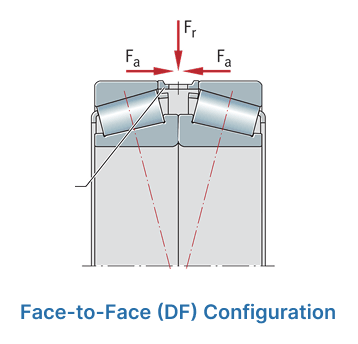

Face-to-Face (DF) Configuration

Characteristics and Applications

The face-to-face (DF) configuration puts the narrow sides of the bearing outer rings together. You use this setup when you need to handle both radial and axial loads from different ways. The pressure lines meet outside the assembly, which changes how the forces move.

You see the face-to-face setup in many heavy-duty machines. It is very common in wind turbine gearboxes. This setup works well for a few reasons:

- It handles both radial and axial loads, especially from helical gears.

- You often use it with a floating cylindrical roller bearing for changing loads.

- It works better than other bearings in tough wind turbine gearbox jobs.

- This setup helps gearboxes last longer and cuts down on repairs and downtime.

When you use the face-to-face setup, the system can take force from both directions and keeps the shaft in the middle. The matched set has two bearings and precision shims. These help you control the position and tightness when setting tapered roller bearings.

Advantages and Disadvantages

The face-to-face (DF) setup gives you some big benefits. One of the best things is that it can handle misalignment. You can see this in the table below:

| Bearing Arrangement | Maximum Permissible Misalignment |

|---|---|

| Single Bearing | 0.0005 rad (0°1’43”) |

| Back-to-Back (O) Arrangement | 0.0005 rad (0°1’43”) |

| Face-to-Face (X) Arrangement | 0.0010 rad (0°3’26”) |

This means the face-to-face setup lets you have about twice as much misalignment as other setups. You get more room for error if your shaft or housing is not lined up just right. This makes it good for machines where some movement or shifting happens.

You should also know the DF setup can take axial forces both ways and supports big radial loads. It keeps the shaft in the center and helps you control the position. But this setup is not as stiff as the back-to-back (DB) setup. The space between the bearing centers is smaller, so the system is less stiff and the axial load capacity is a bit lower. If your machine needs to be very stiff or faces strong moment loads, you might want a different setup.

Another thing to remember is that when the bearing gets hot, the axial clearance in the DF setup gets smaller. This can help you keep tight control in machines like tools with forced cooling. But if you do not control heat well, the bearings can get too hot.

Step-by-Step Installation Sequence

You need to follow careful steps when installing the face-to-face (DF) setup. Here is a simple guide:

- Clean all parts and check for damage before starting.

- Put the bearing cup into the housing bore.

- Place the bearing cone onto the shaft.

- Add the flinger washer to keep out dirt and debris.

- Install the closure, like a seal or cover, to keep grease in and dirt out.

- Do these steps for both sides of the assembly.

Tip: Always press the bearing parts in with even force and at right angles. If you use uneven force, you can damage the bearing or make it not line up right.

Never spin bearings with compressed air. This can break the bearing and cause a safety problem.

To hold and adjust the bearings, use snap rings, washers, and nuts. These parts help you set the right preload or end play when setting tapered roller bearings. Good adjustment makes sure the bearings last long and work smoothly.

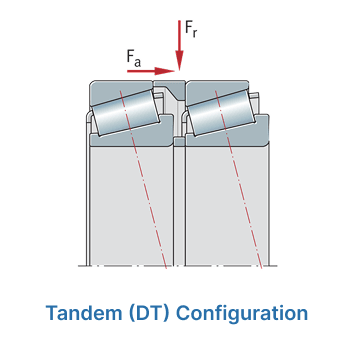

Tandem (DT) Configuration

Characteristics and Applications

You use the tandem (DT) configuration when a machine needs to handle strong thrust loads in one direction. In this setup, both bearings have their contact angles pointing the same way. This design helps the bearings share axial loads more evenly. You often see tandem pairs in machine tool spindles. These machines need high stiffness and very exact shaft placement. The tandem setup gives you double the axial stiffness compared to other setups with the same preload. You get less bending and less runout, so your equipment works smoothly and stays accurate.

When you set tapered roller bearings in tandem, you must watch end play and preload closely. You get the right setting by using factory-matched bearing sets or by changing spacers and nuts. Always use special tools to measure and set the preload. This careful work makes sure both bearings share the load and stops early failure.

Advantages and Disadvantages

The tandem (DT) configuration has some big advantages:

- You get more thrust capacity, which is great for heavy one-way thrust loads.

- Both bearings share radial and axial loads, so the load spreads out better.

- The setup gives you strong axial stiffness, which helps your machine stay straight and lined up.

- You can expect the bearings to last longer because the load is shared.

But the tandem setup only supports axial loads in one direction. If your machine needs to handle thrust both ways, you should pick a different setup. Also, if you do not adjust it right, the bearings may wear out early. Always adjust the tandem pair against a good bearing and use the right tools to measure.

Tip: Check your bearings often and use the right grease or oil. This helps you keep the right preload and makes your bearings last longer.

Key Technical Considerations for Pairing

Clearance and Preload Adjustment

You need to set the right clearance and preload when pairing tapered roller bearings. If you do not, the bearings can fail early or make noise. There are a few ways to help you get these settings right:

- Use nuts, shims, or spacer sleeves to set how tight the bearings are. Adjust these until the fit feels correct.

- Check how much the shaft moves with a dial indicator. This tool shows you the shaft’s movement.

- Turn the shaft and feel how hard it is to turn. You want just the right amount of drag.

- Change the thickness of gaskets or nuts to get the best clearance.

- Spin the shaft while you adjust. This helps the rollers sit in place.

If you make the bearings too tight, they get too hot and wear out fast. If you make them too loose, they get noisy and do not work well. Always use the torque values the maker gives you.

Selection Criteria for Paired Bearings

When you pick bearings for pairing, you need to think about a few things. The right choice helps your machine work well and last longer. Keep these ideas in mind:

- Make sure the bearing rings are supported all the way around. This lets them hold more weight.

- Stop the rings from moving by using tight fits, especially if the ring spins.

- Pick interference fits carefully. Think about how heat or cold will change the size of the rings.

- Use tighter fits and smaller gaps for heavy or sudden loads.

- The surfaces that touch should be flat and at a right angle to the shaft.

- For fast machines, pick bearings with smooth raceways and seals that do not rub much.

- For very exact jobs, matched pair bearings help keep things lined up and share the load.

You also need to match the bearing type and size to your load, speed, and where you use it. For heavy loads, use double or four-row bearings. For fast speeds, pick bearings with smoother surfaces.

Mounting and Alignment Accuracy

Getting the mounting and alignment right is very important for paired tapered roller bearings. If you do not line them up, the load is uneven and the bearings wear out faster. Follow these steps for the best results:

- Control the clearance or preload when you put the bearings in.

- Turn the bearings as you tighten them so the rollers sit right.

- Tighten the nut until the bearing is in place, then loosen it until the wheel spins easily.

- Tighten again until you feel a little drag, then lock the nut.

- Use preset assemblies with spacers for better control in two-row setups.

If things are not lined up, the bearings get stressed and can fail early. Always use the right tools and take your time when you install them.

Common Pairing Problems and Troubleshooting

Failures Caused by Improper Pairing

If you do not pair tapered roller bearings the right way, many things can go wrong. You might see the parts wear out fast, hear strange noises, or have the machine break down suddenly. When the preload is too tight, the bearings get too hot and lose their grease. If the bearings are too loose, the shaft can move too much. This makes the machine shake and puts weight in the wrong places. Both of these problems make your equipment not last as long.

Some common problems are:

- Excessive heat: Bearings get hot if preload is too high.

- Noise and vibration: Loose bearings rattle and do not line up right.

- Seal damage: Bad pairing lets dirt in and grease out.

- Uneven wear: Wrong alignment causes pits or chips on rollers and raceways.

If you see metal pieces, burnt grease, or hear odd sounds, stop the machine and check the bearings right away.

Maintenance and Diagnostic Tips

You can stop most problems by taking care of your bearings and checking them often. Always set the preload so it is not too tight or too loose. Use the right tools, like a hex nut, cotter pin, and a strong washer between the bearing and the nut. These help keep the bearing in place and protect other parts like seals and brakes.

Here are some good tips:

- Clean every part before you put it together.

- Use a dial indicator to check how much the shaft moves.

- Follow the maker’s torque rules.

- Look at seals and washers to see if they are worn out.

Checking your bearings often and using smart tools helps your tapered roller bearings pairing stay strong and your machines last longer.

You get the best results when you do each step carefully.

- Always use the right tools and never rush or skip steps. This helps stop damage.

- Follow all safety rules and double-check your work to make sure it is right.

- Spend time learning how to do things and use tools made for putting in and taking out bearings.

Studies show that putting in bearings the right way and making better designs help machines last longer and work better. If you need help or good bearings, talk to TFL Bearings. Pick us if you want your machines to work well and not worry.

FAQ

What is the best way to check if you installed tapered roller bearings correctly?

Spin the shaft with your hand. It should move smoothly. Use a dial indicator to see how much the shaft moves. If you hear odd sounds or feel bumps, check the alignment and preload again.

How often should you lubricate paired tapered roller bearings?

Follow the maker’s plan for adding grease. Most machines need grease every 6 to 12 months. If your machine is heavy-duty or runs fast, check and grease it more often.

Can you reuse tapered roller bearings after removal?

Do not use bearings again if you see damage or color changes. Always look for cracks or rough spots. If the bearing looks perfect and spins well, you can use it again. But new bearings work better and last longer.

What tools do you need for proper bearing installation?

- Bearing puller or installer

- Torque wrench

- Dial indicator

- Clean rags and gloves

These tools help you set the right preload and check alignment. They also help you keep everything clean while you work.