Tapered roller bearings are very important in car wheel hubs and gearboxes. Their special shape helps them hold both side and up-and-down loads. This makes them great for tough car jobs. Studies show that about one out of three car wheel hubs and gearboxes use a tapered roller bearing. This is because they are strong, last long, and work well. The cone-shaped rollers and slanted setup make more contact. This helps hold the car’s weight, keep gears lined up, and make the bearing work better.

- Industry reports give main reasons for picking tapered roller bearings:

- They handle both side and up-and-down loads well.

- Their shape works for heavy loads and when things are not lined up.

- They last a long time with different car loads.

Tapered roller bearings are still a top pick for many car parts. They help things run smoothly and last longer.

Key Takeaways

Tapered roller bearings can handle side and up-and-down loads. This makes them great for car wheel hubs and gearboxes. Their special tapered shape spreads loads out evenly. It also lowers friction and helps parts last longer in hard conditions. Using two tapered roller bearings together gives more stability. It also spreads the load better and helps the bearings last longer in wheel hubs and gearboxes. You need to install them the right way. You should also add oil often and check them on time. This keeps tapered roller bearings working well and stops them from breaking early. Tapered roller bearings support more load and last longer than other bearings. This is why they are the best choice for strong car parts.

Tapered Roller Bearing Structure

Tapered Design

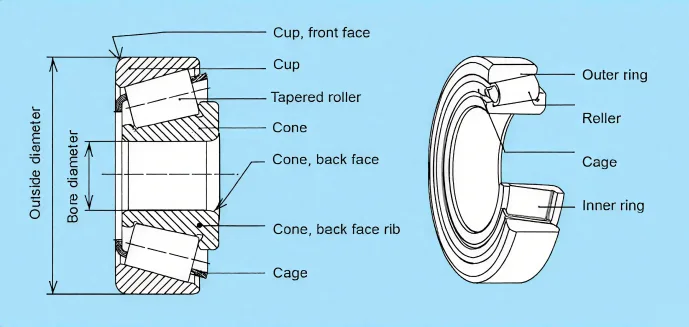

Tapered roller bearings have a special design that is different from other roller bearings. Each one has four main parts. These are the cup, the cone, the tapered rollers, and the cage. The cup is the outer ring. It helps support both side and up-and-down loads. The cone is the inner ring. It holds the rollers and forms the inside track. Tapered rollers fit between the cup and cone. They spread the load over a big area. The cage keeps the rollers spaced out. This helps lower friction and wear. Because of this design, tapered roller bearings work well in small spaces. They also give very accurate performance.

| Component | Description | Contribution to Performance |

|---|---|---|

| Cup (Outer Ring) | Round, cup-shaped outer ring with a track | Supports side and up-and-down loads, fits different setups |

| Cone (Inner Ring) | Inside track with tapered rollers on it | Handles both types of loads, comes in single or many rows |

| Tapered Rollers | Rolling parts with a tapered shape | Spread out the load, lower stress in one spot |

| Cage | Keeps rollers apart | Lowers friction and wear, keeps bearing steady |

Microgeometry is also important. A smooth surface and well-shaped roller crowns help make a good oil layer. This stops edge loading. These things lower friction, make less noise, and help the bearing last longer.

Load Handling

Tapered roller bearings are great at handling both side and up-and-down loads at once. The tapered shape makes more contact between the rollers and tracks. This lets the bearing hold heavy loads and stay steady. In cars, single-row tapered roller bearings can hold up to 150 kN of side load and 75 kN of up-and-down load. Double-row tapered roller bearings can almost double this amount. This makes them good for tough jobs.

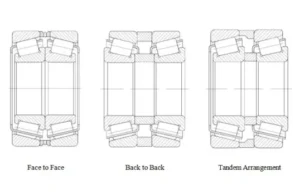

Matched roller bearings can be put together in X, O, or tandem ways. These setups help the bearings handle forces from many directions and make them stiffer. The exact shape and high accuracy of tapered roller bearings help share the load evenly. This means less noise, less shaking, and steady work. The design also helps make a strong oil layer. This lowers friction and keeps the bearing working well.

Applications in Wheel Hubs

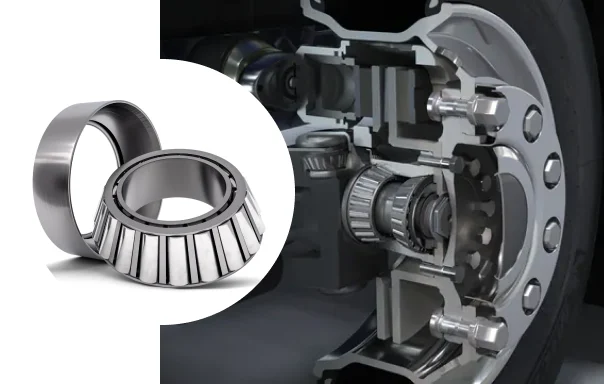

Tapered Wheel Bearings

Tapered wheel bearings are very important in car wheel hubs. These bearings help hold up the car’s weight. They also handle sideways forces when the car turns, speeds up, or stops. The special tapered shape lets them work well with heavy loads. This makes them a good choice for cars. In wheel hubs, tapered roller bearings can hold both up-and-down and side-to-side loads at once. This is needed for wheels to turn safely and smoothly.

| Function/Feature | Explanation |

|---|---|

| Support radial and axial loads simultaneously | Tapered roller bearings hold up big up-and-down and side-to-side forces, which is needed for wheel hubs. |

| Designed for combination loads | The tapered parts let them handle both types of forces well. |

| Load capacity adjustment | The angle can be changed to make them hold more or less weight. |

| Use in pairs | Two bearings are often used together to help with forces from both sides. |

| Reduce friction | The design helps them roll better and lowers friction, so they last longer. |

| Provide rigidity and stability | The tapered shape keeps the bearing stiff and steady when loaded. |

Tapered wheel bearings also help keep the wheels lined up. Their strong build gives the support needed for heavy loads. This is why they are often picked for car wheel hubs, where safety and good performance are important.

Load and Durability

Tapered roller bearings in wheel hubs must handle stress all the time. They do well with heavy loads, like when turning hard, stopping fast, or driving on bumpy roads. The cone-shaped rollers spread out the pressure. This helps stop wear and makes the bearing last longer. Most car wheel hubs with these bearings last between 100,000 and 150,000 miles if driven normally. Heavy-duty hubs may need fixing sooner, but good oil and checks help them last.

Tip: Doing regular checks and using the right oil helps tapered wheel bearings last longer in cars.

Tapered roller bearings also lower friction, so wheels spin easily. This helps save gas and makes rides smoother. Their design keeps the wheel hub steady, even with heavy or sudden loads. Compared to other bearings, tapered wheel bearings last longer and can hold more weight. This makes them the best pick for most cars.

Installation in Pairs

Car wheel hubs often use two tapered roller bearings together. Using two bearings lets them handle forces from both sides. This helps spread out the load and keeps things balanced. When put in right, paired bearings make the wheel hub last longer and work better. The tightness of the bearings is important. If it is too tight, the bearing can break early. If it is too loose, the bearing can move too much and not last as long.

- Using two bearings together means:

- They can handle forces from both directions

- Loads and shocks are spread out evenly

- The wheel hub is steadier and lasts longer

Clean parts and the right oil make paired bearings work even better. Changing both bearings at the same time helps them last and work well. This is very important in cars, where safety and trust matter most.

Note: Always follow the maker’s rules for putting in and caring for wheel hub bearings to stop them from breaking too soon.

Applications in Gearboxes

Shaft Support

Tapered roller bearings help hold up shafts in car gearboxes. These bearings sit at the ends of gear shafts. Their special shape lets them carry both side and up-and-down loads. This is important because it keeps the shafts steady. It also lowers stress on other gearbox parts. The cone shape of the rollers and tracks spreads the load out. This helps stop wear and makes the gearbox work better, even when stressed.

Car gearboxes often use two tapered roller bearings or a double-row bearing. This helps them handle forces from both sides. The way these bearings come apart makes them easy to put in and adjust. This is good for jobs where the shaft must be lined up just right. By holding both the input and output shafts, these bearings help move loads smoothly. This support is needed for gearboxes to work well and last a long time.

- Main benefits of tapered roller bearings for shaft support:

- Carry both side and up-and-down loads

- Give stability and stiffness to shafts

- Allow for careful adjustment and lining up

- Lower wear on parts in fast-moving gearboxes

Note: Good shaft support from tapered roller bearings helps gearboxes run quietly and last longer.

Gear Alignment

Keeping gears lined up is very important in car transmissions. Tapered roller bearings help by holding both types of loads at once. Their special shape makes the contact angle bigger. This lets them hold more weight and spread out stress. This means less wear and a longer-lasting gearbox.

In fast gearboxes, these bearings keep gears steady so they fit together right. They also help cut down friction and heat. This keeps the gearbox running smoothly. When used in pairs, tapered roller bearings can hold up-and-down loads from both sides. This helps keep gears lined up and steady. It is needed for gears to work well and stay accurate.

| Feature | Benefit for Gear Alignment |

|---|---|

| Tapered design | Spreads out loads, lowers friction |

| High load capacity | Handles heavy and sudden forces |

| Use in pairs | Holds up-and-down loads from both sides |

| Precise adjustment | Keeps gears lined up |

Tapered roller bearings make gearbox designs simpler. They remove the need for extra parts to hold different loads. Their strong build helps gearboxes work well in tough and fast conditions. These things make them a top pick for cars where gear alignment and working well matter most.

Efficiency Advances

Modern gearboxes need to work well and have low friction. Tapered roller bearings have changed to meet these needs. New designs use plastic cages, which lower friction by up to 20% compared to steel cages. This makes gearboxes work better, especially with thin oils or when the oil pump is off, like in hybrid cars.

Plastic cages can have more complex shapes and take up less space. This helps keep the oil in place and lowers drag from oil moving around. Because of this, the bearings work well with less oil and at higher speeds. These changes help gearboxes stay cooler and work better.

- Efficiency gains from tapered roller bearings in gearboxes:

- Lower running torque and friction

- Up to 36% less wasted energy during fuel-saving cycles

- More power in a smaller size than ball bearings

- Last longer and make less noise in fast gearboxes

Tapered roller bearings also help cars use less gas. Their self-cleaning action keeps dirt out, which lowers friction even more. Better bearing shapes and strong materials give more power and allow for smaller, lighter bearings. These features make tapered roller bearings the best pick for new transmissions and fast-moving gearboxes.

Tip: Picking the right tapered roller bearing and oil can help gearboxes work better and last longer.

Tapered Roller Bearings in Differentials

Alignment and Wear Reduction

Tapered roller bearings are very important in car differentials. They help hold both up-and-down and side-to-side loads. This spreads out the stress on the differential parts. When the load is spread out, there is less chance of wearing out. These bearings also keep the gears and shafts lined up right. Good alignment is needed for gears to work well. If gears stay lined up, the differential works better and lasts longer.

Shims are thin pieces used when putting the bearings in place. They help set how tight the bearings are. This makes the parts stiffer and keeps them from moving too much. If the bearings are too loose, they can move and wear out fast. Tapered roller bearings can handle small mistakes in how they are put in. This helps stop damage if the shaft bends or is not set just right. Because of this, the differential lasts longer and works better in all kinds of cars and trucks.

Tip: Check the bearings often and make sure they are tight enough. This helps keep everything lined up and stops parts from wearing out too soon.

Smooth Operation

Tapered roller bearings help differentials work smoothly. They hold both up-and-down and side-to-side forces from turning power. Their strong build lets the gears move steady and quiet. This makes the differential work better and with less noise.

New roller bearings are made with very smooth surfaces. This helps lower friction and noise, so the ride feels nicer. Special machines make the bearings smooth and remove tiny rough spots. Good seals keep out dirt and water, which helps the bearings last longer and work well.

- Some things that help the bearings work smoothly are:

- Special shapes inside to make less noise

- Materials that soak up shaking in the housing

- Seals that keep out dirt and other bad stuff

Tapered roller bearings in differentials help cars run quietly and use less energy. Their design helps them last a long time and work well in many types of cars.

Bearing Comparison

Ball Bearings

Ball bearings have small balls that help parts move with less friction. The balls only touch the raceways at one spot. This lets them spin very fast, but they cannot hold much weight. Ball bearings work best in car parts that need to spin quickly and do not carry heavy loads, like electric motors and alternators. They cost less than other bearings and are simple to put in. But they are not good for heavy or mixed loads.

| Bearing Type | Load Capacity | Contact Type | Typical Automotive Applications |

|---|---|---|---|

| Ball Bearings | Lower load capacity | Point contact | High-speed, lighter load components (e.g., electric motors, alternators) |

| Tapered Roller Bearings | Higher load capacity, especially for combined radial and axial loads | Line contact | Heavy-duty applications (e.g., wheel hubs, transmissions) |

Note: Ball bearings are fast and cheap, but they are not as strong as roller bearings for tough car jobs.

Cylindrical Roller Bearings

Cylindrical roller bearings use cylinders instead of balls. These bearings can hold heavy up-and-down loads and let the shaft move a little. They work well in fast gearboxes because they do not make much friction. But they are not good at holding side or push loads. Tapered roller bearings can hold both up-and-down and side loads. This makes them better for gearboxes and wheel hubs, where forces come from many ways. Cylindrical roller bearings are best where speed and up-and-down loads matter most.

Unique Advantages

Tapered roller bearings have special benefits for cars.

| Advantage | Explanation | Automotive Application Impact |

|---|---|---|

| Support for both radial and axial loads simultaneously | The tapered design allows bearings to handle forces perpendicular and parallel to the shaft, eliminating the need for additional bearing components. | Simplifies mechanical design in wheel hubs and gearboxes, improving compactness and efficiency. |

| Increased contact angle between rollers and raceways | The tapered rollers create a greater contact angle, enhancing load-carrying capacity and distributing stress evenly. | Reduces wear and extends service life under heavy loads and harsh conditions. |

| Robust construction and precision manufacturing | Designed to operate reliably in high-speed, heavy-duty, and harsh environments. | Ensures stability and durability in automotive wheel hubs and gearboxes. |

| Conversion of radial loads into axial thrust | Unique geometry allows efficient force transmission and load management. | Maintains gear alignment and reduces friction, improving energy efficiency and smooth operation. |

| Superior combined load handling compared to cylindrical roller bearings | Cylindrical bearings mainly support radial loads, while tapered bearings handle both radial and axial loads effectively. | Provides better performance in automotive applications where combined loads are common. |

| Energy efficiency and operational stability | Reduced friction and heat generation due to refined design. | Leads to longer lifespan and lower maintenance costs in automotive systems. |

- Tapered roller bearings usually cost more than ball bearings because they are more complex.

- They can hold more weight and last longer, which saves money for big vehicles.

- Putting them in and taking care of them can be harder, so the total cost is higher.

- Ball bearings are still a good pick for fast, light parts because they are cheaper.

Practical Considerations

Installation

Putting in tapered roller bearings the right way is very important. It helps cars stay safe and work well. Mechanics use simple steps to set the bearings. These steps stop the bearing from wearing out too soon. They also help the bearing do its job for a long time.

- Clean the bearing and the area around it. Look for any damage.

- Put grease on the inner race. Press the bearing in so it lines up right.

- Tighten the nut while turning the bearing. This takes out extra space but does not make it too tight. Use a torque wrench to match what the maker says.

- Use a dial indicator to check end play. Change the preload if needed to fit the rules.

- Lock the nut with a locking device so it does not come loose.

- Cover the bearing with enough lubricant.

Tip: Mechanics should try to get almost zero axial force preload. Too much preload makes heat and wear. Too little can let the bearing move and make noise.

Lubrication

Good lubrication helps tapered roller bearings last longer. It also keeps them working smoothly. Car wheel hubs often use gear oils that meet API rules, like GL-5. These oils have things in them to stop wear and heat. Mechanics pick oil thickness by load and temperature. SAE 75W-90 is used a lot. Some bearings use grease, which needs to be changed often. Oil baths lower drag and help control heat. Spray and oil systems give more control but need more care.

- Always use the lubricant the car maker says to use.

- Check oil levels and keep them right to stop metal rubbing.

- If you drive hard, check and service the bearings more often.

Failure Modes

Tapered roller bearings can break in different ways. The table below lists common problems, why they happen, and how to stop them.

| Failure Mode | Causes | Prevention |

|---|---|---|

| Corrosion | Dirt, water, bad storage | Store right, use seals, put on coatings |

| Overloading | Too much load, high heat | Use the right bearing, follow load limits |

| Misalignment | Bent shafts, dirt, bad assembly | Check parts, use good tools |

| Seal Failures | Broken or old seals | Use good seals, check them often |

| Spalling | Bad fit, too much load, dirt | Make sure fit is right, use better lubrication |

Note: Checking bearings often and handling them right helps them work well and last longer.

Tapered roller bearings work well in car wheel hubs and gearboxes. Studies say they are good because they:

- Handle both up-and-down and side loads easily

- Last a long time and do not break fast

- Let parts move smoothly, even when going fast

To help them work their best, people should:

- Put them in the right way and use the right tools

- Keep the area clean and use the right oil or grease

- Check how much weight they hold and look after them often

TFL Bearings gives strong tapered roller bearings, good advice, and quick shipping for cars.

FAQ

What makes tapered roller bearings ideal for automotive wheel hubs?

Tapered roller bearings can hold both up-and-down and side forces. Their shape helps cars and trucks carry weight and turn safely. This makes them a good choice for wheel hubs.

How often should mechanics inspect tapered roller bearings?

Mechanics should look at these bearings during regular checkups or every 30,000 miles. Checking early helps find problems, stops breakdowns, and keeps cars safe.

Can tapered roller bearings be reused after removal?

Most experts say to use new bearings after taking old ones out. Using old bearings again can make them fit wrong, wear out faster, or break. Always do what the maker says.

What are signs of a failing tapered roller bearing?

Some signs are strange noises, wheels shaking, or tires wearing unevenly. Mechanics might also feel heat near the wheel hub. Finding problems early stops more damage.

Do tapered roller bearings require special lubrication?

Yes. These bearings need good grease or oil made for cars. The right oil or grease lowers friction, stops overheating, and helps bearings last longer.