Understanding Normal Motor Bearing Sounds

Motor bearing noise is one of the most accessible diagnostic tools available to maintenance professionals and reliability engineers. It offers real-time insight into bearing condition without disassembling or interrupting the system. However, the key is not just to notice when noise occurs—but to understand what that noise means.

Most professionals are trained to detect problematic sounds: knocking, grinding, whines, or irregular vibrations. But fewer are taught what a normal bearing should sound like. This gap in knowledge often leads to unnecessary interventions, wasted labor hours, and even premature replacement of healthy components.

In our previous articles, we’ve explored how to diagnose and address problematic bearing sounds (‘Why Are Your Ball Bearings Making Noise?‘), and we’ve also discussed strategies for reducing noise from a design perspective (‘Reducing Electric Motor Noise…‘).

Now, we’re taking a different approach—one that focuses on sound as a confirmation of health, not just a signal of failure. When you understand the normal sonic footprint of your motor bearings, you’re equipped to make smarter, faster maintenance decisions.

Why Bearings Are Never Truly “Silent”

It is a common misconception that a perfectly functioning bearing should be silent. In reality, the very mechanics of a rolling bearing’s operation generate sound. This inherent noise is a byproduct of several physical interactions that are unavoidable, even under ideal conditions.

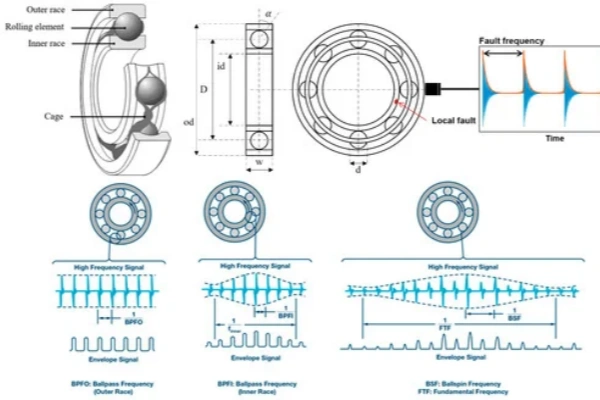

Rolling Element Collisions

Inside a bearing, balls or rollers move between the inner and outer raceways. As they rotate, especially through the unloaded zone, these elements can gently impact the raceways. These micro-collisions are natural and produce a faint sound—usually a steady, soft clicking or ticking that remains consistent in tone and frequency.

Bearings with greater internal clearance may exhibit more audible interactions in this area, particularly at lower loads or during startup. This is not necessarily a defect—just a normal part of the bearing’s physics.

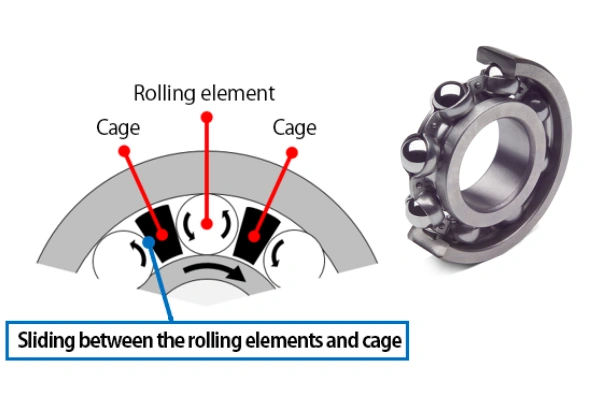

Cage Interaction

The bearing cage, or separator, plays a vital role in maintaining spacing between the rolling elements and guiding their movement. The cage is constantly in contact with the balls or rollers, and this interaction generates a light rustling or brushing noise.

In high-speed applications, this sound may blend into a steady hum. In low-speed environments, it might be easier to isolate and identify. Either way, it’s a sign that the cage is doing its job.

Lubricant Agitation

In grease-lubricated bearings, the lubricant itself is a source of sound. As the rolling elements and cage churn through the grease, they stir and redistribute it. This agitation produces a smooth, low-frequency hum or whirring noise.

Importantly, a sudden absence of this sound could indicate lubricant depletion—while an irregular whooshing or gurgling may suggest over-lubrication or uneven distribution. Paying attention to the rhythm and tone of lubricant-related noise can offer clues about lubrication health.

Friction from Seals and Shields

BBearings with contact seals or shields are designed to protect against contaminants and retain grease. These components rub lightly against the inner ring or rotating parts, producing a faint frictional sound. This is entirely normal.

The noise from seals tends to be a low, consistent rubbing or brushing sound that doesn’t vary much with speed. If you begin to hear squealing, scraping, or fluttering from the seal area, however, that’s a cue to investigate further.

These sounds are fundamental to the operation of any rolling bearing. Therefore, the goal isn’t to eliminate sound but to ensure it falls within the expected range for a healthy component.

Identifying A Healthy Bearing Sound: The Key Characteristics

A healthy motor bearing produces a sound that is consistent, uniform, and free of anomalous frequencies. When a motor operates at a stable speed, these internal interactions should create a predictable and steady acoustic profile.

Consistency and Uniformity

The most defining feature of a healthy bearing is acoustic stability. A good bearing produces a uniform hum or whir that remains consistent across:

- Operating speed

- Load variations

- Temperature changes (within normal range)

There should be no abrupt pitch changes, intermittent clicking, popping, or knocking. Irregular or pulsing sounds typically signal mechanical disturbances or early-stage defects.

The Absence of Abnormal Frequencies

Sound analysis tools, like vibration analyzers and acoustic sensors, can help identify problem frequencies. However, even experienced technicians can use simple listening to catch early warning signs.

Be cautious of:

- High-pitched squeals: often a sign of lubrication breakdown or cage instability.

- Low grinding or growling: typically associated with surface damage on raceways or rolling elements.

- Clicking or snapping: could point to cracks or pitting.

- Variable pitch or beat frequency patterns: may indicate misalignment or imbalance.

A consistent, low-volume sound that matches the motor’s speed is generally a positive sign. Any sudden or gradual change in this acoustic profile warrants further investigation.

The Role of Environment and Application Context

Normal bearing noise can vary depending on:

- Bearing type (ball, roller, angular contact, etc.)

- Lubrication method

- Mounting configuration

- Load and speed profile

- Acoustic properties of surrounding structure

For example, a sealed deep-groove ball bearing in a small HVAC fan may sound completely different from an open spherical roller bearing in a heavy-duty gearbox. This makes it essential to define what’s normal on a per-application basis.

Baseline recordings of new or healthy equipment can be valuable reference points. Over time, any deviation from this baseline should be noted and evaluated, even if the sound still falls within a “normal” range.

Why Choosing the Right Bearing Matters

Understanding the difference between normal and abnormal bearing noise is crucial—but it’s only part of the equation. The quality and precision of the bearing itself directly impacts both performance and acoustic signature.

Poorly manufactured bearings often contain:

- Surface roughness or irregularities

- Inconsistent internal clearance

- Out-of-round raceways or cages

- Contaminants embedded in rolling surfaces

These defects manifest as early-life noise, even when the bearing is freshly installed. They can also shorten service life and complicate diagnostics by introducing erratic or misleading sound profiles.

Noise is not always the enemy. In fact, it can be a vital sign of health—if you know how to interpret it. Rather than striving for silence, aim for sonic consistency and predictability. Recognize the normal hum of a healthy bearing and use it as your first line of defense against premature failure.

Your ears, combined with quality components and smart diagnostics, are powerful tools.

If you’re tired of second-guessing your equipment’s performance or replacing bearings prematurely, it’s time to shift your strategy. Start by partnering with a bearing manufacturer that delivers not just products—but peace of mind.

Choose a bearing that speaks to its quality.

Contact TFL Bearings today and let us help you find the perfect solution for your application.