The main difference between split roller bearing and one-piece designs is in how workers put them in and take care of them. Split roller bearing lets workers reach shafts and parts fast. This helps save time when fixing things. In factories, almost half of bearing problems happen because people put them in wrong or do not handle them right.

| Cause of Bearing FailurePercentage of Premature Failures | |

|---|---|

| Improper installation or mishandling | 48% |

| Improper mounting (installation) | 5% |

| Indirect failures (transport, storage, handling) | 4% |

Picking the right bearings can help machines break down less. It also makes the equipment work better.

Key Takeaways

- Split roller bearings can be put in without taking off other machine parts. This saves time and cuts down on how long machines stop working.

- One-piece roller bearings are good for new machines or ones you can reach easily. But you have to take out the whole shaft to fix them.

- Split roller bearings fit in small spaces and hard jobs. They make repairs quicker and safer for workers.

- Picking the right bearing saves money, helps machines work better, and keeps workers safe.

- Split roller bearings cost more at first but save money later. They do this by lowering work time and stopping less often.

Differences

Design

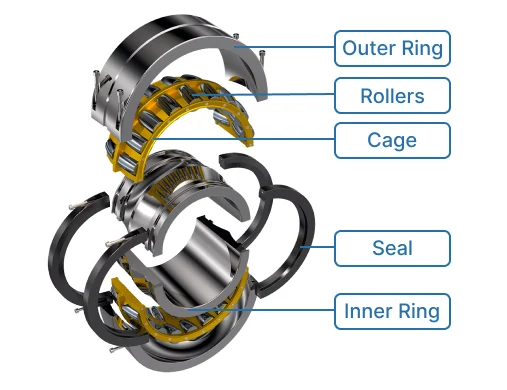

How a bearing is made is very important. It affects how well it works and where it can be used. Split roller bearing has a special build. Its parts, like the inner ring, outer ring, cage, and rolling elements, are split into two halves. This lets the bearing fit around a shaft without taking off other machine parts. One-piece roller bearings are different. They have solid rings and a cage made from one piece. To use them, the shaft must be easy to reach for putting in or taking out.

The table below shows the main differences in how these bearings are built:

| Feature | One-piece Roller Bearings | Split Roller Bearings |

|---|---|---|

| Structure | Solid, one-piece rings and cage | Horizontally split into two halves |

| Installation | Requires full shaft disassembly | Can be installed around the shaft without dismantling surrounding machinery |

| Downtime During Replacement | High | Low |

| Maintenance Complexity | High | Medium to Low |

| Ideal Applications | Machines with open access | Confined or hard-to-access areas |

Split roller bearing works well in tight spaces. Its split design makes it easy to get to and change, even if other machines are close by. One-piece bearings are strong but take more time and work to put in or take out.

Installation

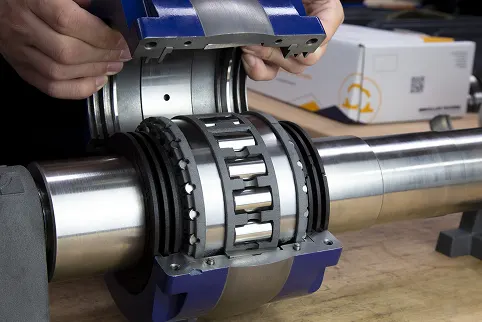

How you put in these bearings is very different. Split roller bearing can go right around a shaft. You do not have to move or take apart other machines. This saves time and money. It also helps keep other machine parts safe during repairs.

One-piece roller bearings need the whole shaft taken out. Workers often have to take apart nearby equipment to reach the bearing. This takes longer and can stop work for a while. In places where time is important, split roller bearing is a better choice.

Tip: Using split roller bearing in hard-to-reach spots can save a lot of work and lower mistakes when putting it in.

Performance

How well a bearing works matters a lot in factories. Both split roller bearing and one-piece roller bearings can handle heavy loads and fast speeds. But split roller bearing has some special good points:

- The split design makes it easy to check, oil, and change without moving other machines.

- You can use regular straight shafts, so you do not need special parts.

- Strong materials like hardened steel and ductile iron make it last longer.

- It can line up by itself, even if the shaft is off by up to 3°.

- Split roller bearing cuts down on repairs, stops, and lost work, so it saves money.

- In tough jobs like mining, cement, and power plants, split roller bearing lasts a long time and works well.

- These bearings also save power and fit the shaft better than sleeve bearings.

One-piece roller bearings work well when there is lots of space. They can hold heavy loads and are dependable. But you have to take everything apart to fix them, which takes more time and costs more.

Note: Split roller bearing is best when you need fast repairs and little trouble. One-piece roller bearings are good for new machines or places that are easy to reach.

Split Roller Bearing Applications

Hard-to-Access Equipment

Many machines have parts that are hard to reach. Sometimes, bearings are hidden behind heavy covers or other equipment. Workers have a tough time checking or changing these bearings. Solid bearings need the whole shaft and nearby parts taken apart. This takes a lot of time and costs more money. It can also make the job less safe.

Split roller bearing helps with these problems. Its two-piece design lets workers put it on or take it off without moving other equipment. They can open the bearing, fit it around the shaft, and close it. No special tools or heavy lifting are needed. This way, workers do fewer steps, going from ten steps to just four. Maintenance teams finish faster and do not have to work in unsafe spots. Machines stop working for less time, up to 90% less.

Tip: Using split roller bearing in hard-to-reach places saves money and keeps workers safer.

Some common uses for split roller bearing in tight spots are:

- Conveyor systems in mining and moving big materials

- Gearboxes and drives in wind turbines

- Shafts in boats and ships

- Pumps and fans in power plants

Heavy Industry Uses

Heavy industries need strong and dependable bearings. These jobs include mining, steel mills, wind energy, and power plants. Machines here work hard, face tough conditions, and run for a long time. Bearings must deal with dirt, heat, shaking, and heavy shafts.

Split roller bearing is a good fit for these jobs. Its split design lets workers change it fast, even on big or tricky machines. They do not have to take off couplings, gearboxes, or other heavy parts. This keeps machines running and stops are short.

Here are some real-life ways split roller bearing is used in heavy industry:

| Industry | Typical Applications | Why Split Roller Bearing? |

|---|---|---|

| Mining | Conveyor pulleys, crushers, bucket elevators | Handles dirt, easy to replace, reduces downtime |

| Steel Mills | Rolling mill rolls, pipe forming machines | Withstands heat, supports heavy loads |

| Power Generation | Turbine shafts, generator drives, cooling fans | Quick maintenance, high reliability |

| Wind Energy | Main shafts, gearboxes, yaw drives | Fits large assemblies, supports heavy loads |

| Marine | Propulsion shafts, winches, deck machinery | Easy access, resists corrosion |

- In mining, split roller bearing stands up to dirt and helps conveyor pulleys last longer.

- Steel mills use them to hold up rolling mill rolls in hot and tough jobs.

- Wind turbines use split roller bearing for main shafts and gearboxes, so repairs are quick and turbines keep spinning.

- Power plants use split roller bearing in pumps and fans, so they can fix things fast and avoid shutdowns.

Split roller bearing also has special seals. These seals keep out dust and water, which protects the bearing and makes it last longer. The design keeps the bearing lined up, even if the shaft bends or moves. This stops early breakdowns and helps machines work well.

Note: Big companies like SKF, Timken, and Schaeffler make split roller bearing for these tough jobs. More than 100 million of these bearings are used around the world, and the number is growing as more industries use them.

One-Piece Roller Bearing Applications

New Assemblies

Engineers pick one-piece roller bearings for new machines. These bearings work best when the load is mostly from the side. The base must give full support. Designers can plan for strong mounting and clear loads. One-piece housings are very stiff. This helps in machines that do not need to move or line up by themselves.

Common uses are:

- Electric motors with straight shafts

- Gearboxes in factories

- Farm machines with open frames

- HVAC fans and blowers

One-piece bearings are ready to use when they arrive. They are greased, sealed, and set with the right gap. This makes it easier to put them in and lowers mistakes. It also makes building new machines faster. This helps the bearing last longer. These bearings usually cost less at first, especially small ones. For big custom machines, the price difference is not as big.

Tip: For new machines, use one-piece bearings if you do not need to take out the shaft often and the area is easy to reach.

Easy-Access Equipment

One-piece roller bearings are good when you can remove the shaft easily. This happens in things like conveyor rollers, pump parts, and other open machines. Workers can slide out the shaft, change the bearing, and get the machine working again fast.

Main good points in these cases:

- Quick to put on by sliding and bolting down

- Fewer parts, so fewer mistakes

- Lower starting cost than split bearings

But if the shaft is hard to get to or blocked by other machines, it is harder to remove. Then, split bearings are better for fixing. For easy-to-reach machines, one-piece bearings keep stops short and save money.

| Application Type | Best Bearing Choice | Reason |

|---|---|---|

| New equipment builds | One-piece roller | Lower cost, easy installation |

| Open, accessible shafts | One-piece roller | Quick removal and replacement |

| Confined or complex | Split roller | Easier maintenance, less downtime |

Note: One-piece roller bearings work well in many normal jobs, but always think about how easy it is to reach the shaft and how you will fix it later.

Cost and Maintenance

Upfront Cost

Split roller bearings cost more at first than one-piece roller bearings, especially for small sizes. Their special design and extra work make them pricier. As bearings get bigger, the price gap gets smaller. For very large bearings, both types cost about the same. The extra money spent on split bearings is like paying for one solid bearing replacement. Over time, split bearings save money because they are easier to fix and cause less machine downtime. This makes them a smart choice for many companies.

Even though split bearings cost more at first, they save money later because they are faster to install, last longer, and keep machines running.

Downtime and Labor Savings

Split roller bearings save lots of time when putting them in or fixing them. Workers can put these bearings on a shaft without taking apart other machines. This can make the job up to 90% faster than with one-piece roller bearings. When repairs are quicker, machines start working again sooner. Companies spend less on labor because workers do not need to take machines apart for hours or days. The simple design also means workers make fewer mistakes, which saves even more money.

- Split bearings are easy to check and change.

- No special tools or heavy lifting are needed.

- Labor and downtime costs go down, so workers can do other jobs.

Safety Benefits

Split roller bearings make work safer. Workers do not have to lift heavy parts or squeeze into small spaces as much. The split design lets them put in, check, or change bearings without moving the shaft or big machine parts. This lowers the chance of getting hurt from lifting or working in tough spots. Special seals from brands like SKF and Schaeffler keep out dust and water, which protects the bearing and the worker. Clear labels and easy steps help workers avoid mistakes, making the job safer and faster.

Split bearings help stop accidents and keep workers safe by making repairs easier and less dangerous.

Pros and Cons Table

Picking between split roller bearings and one-piece roller bearings depends on what the machine needs and where it works. The table below shows the main good and bad points of each type. This helps workers and engineers pick the best one for their machines.

| Feature | Split Roller Bearings | One-Piece Roller Bearings |

|---|---|---|

| Installation | Fast to put on around shafts. No need to move other parts. | Must take out the whole shaft. Often needs more work to remove. |

| Maintenance | Simple to check and swap. Less downtime and lower labor costs. | Harder to reach for fixing. Takes longer to change. |

| Initial Cost | Costs more at first, especially for small sizes. | Cheaper at the start for most normal sizes. |

| Safety | Less heavy lifting. Fewer steps. Safer for workers in tight spots. | More lifting and moving. Higher chance of getting hurt in small spaces. |

| Performance | Can hold heavy loads. Lines up by itself if the shaft is not straight. | Strong and works well. Best for open and easy-to-reach machines. |

| Best Applications | Good for hard-to-reach, big, or tricky machines. Used in heavy jobs and important equipment. | Best for new machines or places where the shaft is easy to get to. Used in normal equipment. |

Tip: Split roller bearings are best when machines are hard to reach or when stopping work costs a lot. One-piece roller bearings are good for new machines or places where you can take out the shaft easily.

Workers should look at the table before picking bearings for their next job. Picking the right one can save time, money, and help keep everyone safe.

Picking the right bearing is based on a few things. The table below shows what you should think about:

| Key Factor | Split Roller Bearings | One-Piece Roller Bearings |

|---|---|---|

| Shaft Axial Movement | Lets the shaft move or stay in place when hot | Not as good for moving shafts |

| Load Types Supported | Works with both sideways and end-to-end loads | Best for sideways loads; end-to-end can change |

| Maintenance | Fast and simple to reach; less time stopped | Takes more time to fix |

Experts say you should pick a bearing that fits the load, speed, heat, and how often you need to fix it. TFL Bearings gives help, guides, and advice so people can choose the right bearing.

FAQ

What is the main benefit of using split roller bearings?

Split roller bearings let workers put in or change bearings without moving other machine parts. This design helps machines stop for less time and saves on work costs. Maintenance teams can finish jobs faster and keep machines working longer.

When should engineers choose one-piece roller bearings?

Engineers pick one-piece roller bearings for new machines or when it is easy to reach the shaft. These bearings cost less at first and work well in open areas. They give strong support for many normal uses.

Do split roller bearings require special tools for installation?

Most split roller bearings do not need special tools to put in. Workers can open the bearing, fit it around the shaft, and close it with regular hand tools. This makes the job safer and saves time.

How do split roller bearings improve worker safety?

Split roller bearings mean workers do not have to lift heavy things or squeeze into small spaces. Workers spend less time in dangerous spots. The design helps stop injuries when putting in or fixing bearings.

Can split roller bearings handle high loads and speeds?

Yes. Split roller bearings are made from strong materials and smart designs. They can hold heavy loads and work at high speeds in tough jobs like mining, steel, and power plants.