You use big machines every day, so you know bearings are very important. If you make a small mistake when putting in or handling a spherical roller bearing, it can cause the machine to stop working. This can also lead to repairs that cost a lot of money. Sometimes, a tiny problem with a bearing can cause huge losses in production. These losses can be much more than the price of the bearing. Problems like not lining up parts right, not using enough oil, or letting dirt get in can make bearings wear out fast. These problems can also cause the machine to break badly. Spherical roller bearings hold heavy weights and help when parts are not lined up right. This makes them very important for big machines. Using the right bearings keeps your machines safe and helps stop expensive breakdowns.

Key Takeaways

- Use the right tools and steps to put in spherical roller bearings. This helps stop damage and early failure.

- Keep bearings clean and use the right kind and amount of lubricant. This stops them from getting too hot and wearing out.

- Always line up bearings carefully to lower stress and help them last longer. Even small mistakes in alignment can cause big issues.

- Keep dirt, dust, and chemicals away from bearings by using seals and shields. Work in clean areas to stop contamination.

- Check bearings often for noise, heat, and shaking. Change them on time to stop expensive machine problems.

Spherical Roller Bearings Basics

What They Are

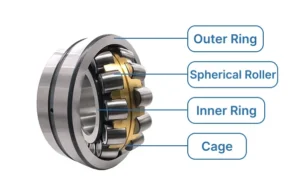

Spherical roller bearings are found in most big machines. They have a special shape to help with hard work. Each one has an inner ring, an outer ring, a cage, and two rows of rollers. The rollers are set at an angle and fit into a curved path. This lets the bearing change if the shaft bends or moves. The cage keeps the rollers apart so they do not touch each other.

- Spherical roller bearings can hold heavy loads from the side and end.

- They can still work if the shaft is not straight.

- These bearings are used in mining machines, conveyors, and other big machines because they last long and lower friction.

- Their strong build helps them handle shaking, bumps, and parts not lining up.

Tip: Pick good spherical roller bearings for your machines. This helps stop early problems and keeps your machines working longer.

Why They Matter

Big machines help your business run every day. Spherical roller bearings are very important for this. Their design lets them carry big weights and deal with parts moving out of place. Other bearings, like needle or tapered roller bearings, cannot handle these problems as well. Spherical roller bearings help your machines work well, even when things get rough.

- These bearings hold both side and end forces, which is needed for hard jobs.

- They can line up by themselves, so your machines have less stress if parts move.

- Spherical roller bearings help stop machine stops because they do not break easily from shaking or hits.

- Newer types can go faster and stay cool, which saves power and makes them last longer.

- Special seals and coatings keep out dirt and water, so they are good for big machines in tough places.

You should always use good bearings in your machines. This keeps your machines safe and working their best.

Common Installation Mistakes

When you put in spherical roller bearings, you can face problems. Even small mistakes can make the bearing break and stop the machine. You need to know what can go wrong to keep your machines working well.

Improper Tools

Some workers use hammers or screwdrivers to install bearings. These tools push too hard in some spots and can hurt the bearing. If you use a hammer, you might dent the raceways or rollers. These dents are called brinelling. Brinelling makes the bearing shake and sound loud. Over time, these dents make the bearing break early.

Tip: Always use special tools like bearing pullers, presses, and centering tools. These tools push evenly and keep the bearing safe. Wear gloves and keep your area clean to stop dirt from getting in.

A table of good tools for bearing installation:

| Tool Type | Purpose |

|---|---|

| Bearing Puller | Takes out old bearings safely |

| Hydraulic Press | Puts in bearings with even force |

| Alignment Tool | Makes sure parts line up right |

| Torque Wrench | Tightens bolts just right |

| Micrometer/Dial Gauge | Checks fit and alignment |

Using the right tools helps you stop bearing problems and makes your bearings last longer.

Bearing Installation Damage

Putting in bearings the wrong way is a big reason they break. Dropping or hitting a bearing can cause dents or cracks. Even a small hit can make damage you cannot see. This damage gets worse over time. Heating the bearing too much is another mistake. If you make it too hot, the metal gets weak and does not last long.

Always handle bearings gently. Keep them in their box until you need them. Before you put them in, check for any damage. Clean all parts to get rid of dirt and grease. When you put in the bearing, push slowly and do not use too much force. Take your time and do not rush.

Note: Experts say to heat bearings to 80°C-100°C for tight fits. Use an oil bath or heater with a temperature control so you do not get it too hot.

If you skip these steps, you can hurt the bearing. This can make the machine shake, get loud, and break early. These mistakes can stop your machines and cost you money.

Misalignment Issues

Not lining up the bearing right is a big problem. If the bearing is not straight, it gets pushed unevenly. This makes it wear out fast. Studies show that misalignment causes shaking and cracks on the bearing. Special tools can find these problems, but you can stop them by doing things the right way.

Always use alignment tools and measuring devices when you put in bearings. Just looking is not enough. Turn the shaft by hand after you finish to make sure it moves smoothly. Tighten the bearing with the right force, just like the maker says. Lining up the bearing right lowers stress and helps it last longer.

Callout: Bearings can handle a little misalignment (about 2° to 3°), but you should not count on this to fix bad installation.

If you avoid these mistakes, you keep your machines safe and stop bearing failure. Good alignment, careful work, and the right tools are very important for every bearing installation.

Lubrication and Contamination

Improper Lubrication

It is very important to use the right amount of lubricant on spherical roller bearings. If you do not use enough, the metal parts rub together. This makes them hot, noisy, and wear out fast. If you use too much grease, it traps heat inside. The bearing gets hotter and the seals can get damaged.

Some common mistakes with lubrication are:

- Using too much or too little lubricant

- Picking a lubricant that is not right for your machine

- Not changing the lubricant often enough

- Using grease when oil is needed

- Choosing the wrong grease base for your job

- Letting dirt or water mix with the lubricant

Tip: Always follow a schedule for maintenance and lubrication. Use the correct type and amount of lubricant for your bearings.

Studies show that about 70% of spherical roller bearing failures in wind power and other heavy machines are from lubrication problems. High speeds and heavy loads can break down the lubricant. This makes the oil film too thin or even disappear. The bearing is not protected. When this happens, the bearing can get scored, galled, or spalled.

Here is a quick guide for lubrication problems and how to fix them:

| Lubrication Issue | Effects on Bearings | Recommended Practices |

|---|---|---|

| Under-Lubrication | Metal scraping, heat, grease breakdown, raceway damage | Check needs, set a schedule, use the right amount |

| Over-Lubrication | Grease churning, energy loss, temperature spikes | Use auto systems, pick the right grease for speed and heat |

Using the right lubricant and putting it on the right way helps your machines last longer. Your spherical roller bearings will work better and not break as fast.

Contamination Risks

Contamination is also a big problem for spherical roller bearings. Dust, dirt, and metal bits can get inside and mix with the lubricant. These hard pieces scratch and wear down the bearing. Over time, this causes scuffing, pitting, and early failure.

The most common things that get in are:

- Dusts like silicon dioxide (SiO2)

- Carbon-graphite dust

- Stainless steel bits

- Coarse test dust

These particles break through the oil film and make metal touch metal. This makes the bearing wear out faster and can cause cracks or spalling. If you do not use good seals or shields, dirt gets in more easily. Even when you put the bearing in, dirt can get inside if the area is not clean.

Note: Dirt mixed with lubricant acts like sandpaper inside your bearings. This can ruin the surfaces and make your spherical roller bearings not last as long.

To stop contamination, you should:

- Use seals and shields to block dust and metal chips.

- Pick sealed bearings for wet or dirty places.

- Use stainless steel or ceramic bearings if you work with water or chemicals.

- Keep your work area clean.

- Use the right lubricant and keep it clean when you put it on.

Sealed spherical roller bearings use rubber or elastomer seals to keep out dirt and hold in lubricant. These seals mean you do not have to do maintenance as often and your bearings last longer.

Chemical Exposure

Chemicals can also hurt spherical roller bearings. If your machines work with water, acids, or other harsh chemicals, the bearings can rust or corrode. Chemicals can break down the lubricant. This makes it not protect the bearing well. Water can wash away grease and cause rust on the metal.

You can protect your bearings from chemicals by:

- Using bearings made from stainless steel or with special coatings

- Picking sealed bearings to keep out water and chemicals

- Using lubricants that do not break down from chemicals

- Checking your bearings often for rust or corrosion

Callout: Chemicals not only make the bearing weak but also ruin the lubricant. This means the bearing does not get enough protection and fails faster.

If you follow these steps, you keep your spherical roller bearings safe from dirt and chemicals. Good maintenance and lubrication help you avoid costly stops and keep your machines working well.

Fit, Preload, and Replacement

Incorrect Fit

You need the right fit between spherical roller bearings and their shaft or housing. If the fit is too tight, the bearing can get squeezed. If the fit is too loose, the bearing can move or spin where it should not. This movement, called bearing creep, causes micromovements that lead to fretting corrosion. You may see red or black marks on the bearing surfaces. These marks show that the bearing’s integrity is at risk. When the fit is wrong, the preload weight can shift, and the shaft may not turn as it should. This increases strain and leads to early wear or failure. ISO 286 gives you the right tolerance zones for fit. Always check fit tolerances and use proper mounting techniques. Good fit helps you avoid vibration, uneven load, and rough wear. You protect bearing integrity and keep your equipment running longer.

Tip: Use measuring tools to check fit before installing spherical roller bearings. This step helps you prevent bearing creep and keeps your machines safe.

Preload Problems

Preload means the force that holds the bearing parts together. If you set too much preload, the rings clamp down on the rollers. This makes the bearing hard to turn and heats it up. You may notice noise, trouble turning the shaft, or damage to the cage and raceways. Too much preload can cause deformation, fatigue spalling, or even cone bore contraction. If you set too little preload, the bearing may move too much and wear out fast. Always select spherical roller bearings with the right internal clearance. Make sure the fit in the housing and shaft is correct. Check for free rotation before you start the machine. These steps help you avoid common troubleshooting issues and keep your bearings working well.

- Signs of preload problems:

- Noise during operation

- Hard to turn the shaft by hand

- Wear in odd places

- Damage to retainers or raceways

Delayed Replacement

You should not wait too long to replace spherical roller bearings. If you delay, the bearing can overheat, wear out, or become misaligned. This can damage other parts like belts and motors. Sometimes, bearing failure leads to motor burnout and long downtime. You may not have a set replacement interval, but you must watch for signs of trouble. Poor lubrication, wrong sizing, or bad fit can make bearings fail early. Sealed-for-life bearings depend on the life of their lubricant. If you ignore replacement, you risk losing the integrity of your whole system. Regular troubleshooting and inspection help you spot problems early and avoid costly repairs.

Note: Always consider the operating temperature and environment when choosing lubricants. This helps you avoid viscosity issues and keeps your spherical roller bearings safe.

Prevention and Downtime Reduction

Bearing Installation Best Practices

You can stop misalignment by following each step when installing spherical roller bearings. Always check the manufacturer’s instructions before you start. Clean the bearing and where it will go to keep out dirt. Use special tools like alignment tools and torque wrenches for a good fit. Put on the right lubricant and seals to protect the bearing. Tighten bolts to the torque the manufacturer says. After you finish, run the machine slowly and listen for strange sounds. Use vibration tools to look for problems. Check if the bearing is lined up right and fix it if needed. Doing these steps helps you avoid problems and makes your bearings last longer.

Step-by-step installation process:

- Read the manufacturer’s instructions before you begin.

- Check and clean all parts first.

- Use alignment tools to set the bearing in place.

- Add the correct lubricant and seals.

- Tighten bolts to the right torque.

- Start the machine slowly and listen for odd sounds.

- Check for vibration and fix alignment if needed.

- Do these steps for every bearing you install.

Maintenance Tips

You can make spherical roller bearings last longer by doing good maintenance. Keep bearings, shafts, and housings clean when you put them in. Store bearings in their box until you need them. Use the right way to mount each size—cold for small ones and heat for big ones. Pick the right shaft and housing fit for best results. Use bearing pullers and heaters to take out bearings safely. Lubricate often with the right grease. Some machines need special grease to stop electrical damage. Pick quality spherical roller bearings so you do not have to fix them as much. Ask experts for help and training to set up a good maintenance plan and avoid mistakes.

Inspection Routines

Good inspection routines help you find problems early. Check for noise, shaking, and heat often. Use your eyes, ears, and hands—look for leaks, listen for odd sounds, and feel for heat. Clean the area before you check. Use tools like vibration testers, heat cameras, and sound monitors for better checks. Operators should check every day, and you should have regular inspections too. Predictive maintenance can cut downtime by 85%, make bearings last 60% longer, and lower costs by 70%. The chart below shows how much money you can save with predictive maintenance:

Always use good bearings and follow each step for installation, maintenance, and inspection. Training and expert help make sure you get the best from your spherical roller bearings and have less downtime.

You keep your machines safe when you take care of spherical roller bearings. Handle, install, and maintain them carefully. Use the right amount of lubricant and check them often. Always follow what the manufacturer says. These steps lower friction and stop parts from wearing out fast. Doing this helps you avoid most bearing problems. Your machines will keep working longer. Studies show that good care makes bearings last longer and stops breakdowns. Pick TFL Bearings for strong spherical roller bearings and helpful support. We help your machines work better and last longer.

FAQ

What signs show that a spherical roller bearing is failing?

You may hear unusual noise or feel vibration. The bearing may get hot or leak lubricant. You might see metal shavings near the bearing. These signs mean you should check and replace the bearing soon.

How often should you lubricate spherical roller bearings?

You should follow the machine maker’s schedule. Heavy use or dirty places need more frequent lubrication. Always use the right grease or oil. Check the bearing often to keep it running well.

Can you reuse a spherical roller bearing after removal?

You should not reuse bearings. Removal can cause hidden damage. Even if the bearing looks fine, small cracks or dents may exist. Always use a new bearing to keep your machine safe.

What is the best way to store spherical roller bearings?

Store bearings in their original box. Keep them in a dry, clean place. Do not open the box until you need the bearing. This keeps out dust and moisture.

Why does proper alignment matter during installation?

Proper alignment spreads the load evenly. Misalignment causes stress and early wear. You protect your machine and extend bearing life when you align parts correctly.