Introduction

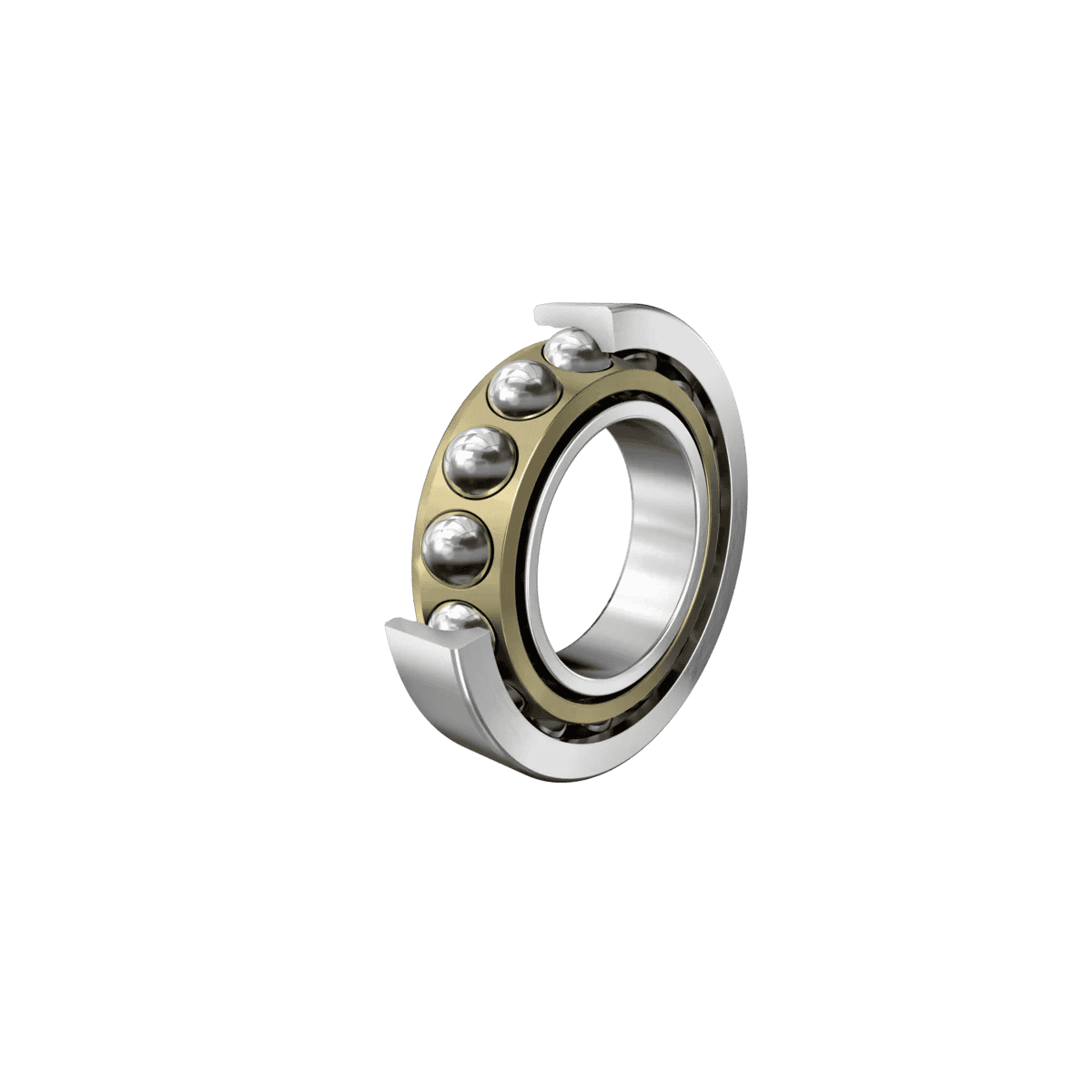

Single row angular contact ball bearings are critical components in machines that demand high speed and precision. You’ll find them in everything from car motors to factory robots, where they handle heavy loads and reduce friction.

But with so many bearing types available, how do you know if a single-row design is right for your project? This guide explains everything you need to know!

What Are Single Row Angular Contact Ball Bearings?

Key Design Features

Single row angular contact ball bearings have a unique design to handle both radial and axial loads. Here’s what makes them special:

- Contact Angles: They operate at 15°, 25°, or 40° contact angles between the inner and outer rings. Higher angles (e.g., 40°) support heavier axial loads.

- Single vs. Double Row: Unlike double row bearings, single row designs are lighter and ideal for high-speed applications.

- Materials: Most are made of chrome steel, but ceramic hybrids are used for extreme heat (up to 220°C/428°F).

Why Choose Them Over Other Bearings?

- Speed & Precision: They outperform deep groove ball bearings in high-speed setups (up to 15,000 RPM)

- Space-Saving: Their compact design fits tight spaces in machines like CNC routers.

Top 4 Applications of Single Row Angular Contact Ball Bearings

(Target keywords: single row angular contact ball bearing application, industrial ball bearings)

- Machine Tool Spindles

Single row bearings ensure precision in CNC machines. For example, a 7205B bearing (25° contact angle) is commonly preloaded to reduce vibration during cutting.

- Electric Vehicle Motors

They manage axial forces in EV motors, especially during sudden acceleration. SKF’s E2 series reduces energy loss by 30% [SKF Engineering Report, 2021].

- Aerospace Actuators

Lightweight ceramic bearings (e.g., Si3N4) are used in drone rotors to handle rapid direction changes.

- Industrial Pumps

Their ability to handle axial thrust makes them ideal for water pumps in harsh environments.

How to Install Single Row Angular Contact Ball Bearings

Step-by-Step Installation Guide

- Clean Surfaces: Remove dirt from shafts and housings using a lint-free cloth.

- Preload Adjustment: Apply light preload (0.02–0.05 mm axial clearance) for high-speed setups [ISO 104:2020].

- Temperature Control: Heat bearings to 80–90°C (176–194°F) for easier mounting.

Common Mistakes:

- Avoid hammering bearings directly (use a press tool).

- Never mix grease types.

Choosing the Right Bearing: Loads, Numbers, and Lifespan

Load Capacity Calculation

Use this formula to estimate dynamic load (Cr):

Cr=Fr/0.8+Fa/0.6

Where Fr = radial load, Fa = axial load.

Understanding Bearing Numbers

Example: 7208BECBP

- 72: Series (medium duty)

- 08: Bore diameter (08 × 5 = 40 mm)

- B: 40° contact angle

- EC: Optimized for electric motors

| Bearing Number | Bore (mm) | Outer Diameter (mm) | Width (mm) | Dynamic Load (kN) | Static Load (kN) | Contact Angle | Typical Applications |

|---|---|---|---|---|---|---|---|

| 7205 B | 25 | 52 | 15 | 16.8 | 10.5 | 25° | Machine tool spindles, small pumps, robotic arms |

| 7305 B | 25 | 62 | 17 | 24.3 | 15.2 | 40° | Heavy-duty gearboxes, conveyor systems, wind turbine yaw drives |

| 7208 BECBP | 40 | 80 | 18 | 29.5 | 19.6 | 25° | Electric vehicle motors, CNC machining centers |

| 7308 B | 40 | 90 | 23 | 42.7 | 26.5 | 40° | Construction equipment, mining machinery, helicopter rotor systems |

| 71806 C | 30 | 42 | 7 | 6.2 | 3.8 | 15° | Dental drills, semiconductor wafer handlers, drone gimbal motors |

Maintenance Tips to Extend Bearing Life

- Lubrication: Use synthetic grease (e.g., Mobil Polyrex EM) every 6–12 months.

- Vibration Checks: Replace bearings if vibration exceeds 4.5 mm/s [ISO 10816-3].

FAQs About Single Row Angular Contact Ball Bearings

- Can they handle reverse axial loads? No—they’re designed for one-directional loads. Use back-to-back pairs for bidirectional forces.

- What does C3 mean in bearing codes? C3 indicates larger internal clearance for high-temperature environments.

Conclusion

The ideal combination of strength, speed, and space efficiency is provided by single row angular contact ball bearings, which are ideal for updating wind turbines or manufacturing factory robots.

From their specialized contact angles to their role in cutting-edge EVs, these bearings prove that small components can make a massive impact.

Need Expert Help? At TFL Bearings, we live and breathe bearings. Our team provides:

- Free technical consultations to match you with the right bearing (C3 clearance? 40° contact angle? We’ve got you covered).

- Lifetime support – From installation guides to load calculations.

Email info@sdtflbearing.com or call +8615806631151 to explore our catalog of single row angular contact ball bearings. Let’s keep your machines running smoother, longer, and faster – together.