If you hear odd noises or see machines get too hot, you may have roller bearings problems. Acting fast can stop long breaks and big repair bills. When roller bearings fail, companies can lose up to $260,000 every hour. In some places, like car factories, this loss can be $2.3 million each hour. If you ignore roller bearings faq or skip regular checks, you could lose 20% of your plant’s work time each year. If you find problems early, you can fix them fast and keep machines working. Use this roller bearings faq as your easy guide for quick fixes and better care.

If you need expert help or want good roller bearings, TFL Bearings is here to help you.

Key Takeaways

Roller bearings lower friction and help machines move easily with heavy weight. Most bearing problems happen because of bad lubrication, dirt, wrong alignment, or too much weight. Checking for strange sounds, heat, and leaks often helps find problems early and stops expensive damage. Use the correct grease, keep bearings clean, and put them in the right way to make them last longer. Simple fixes like cleaning, using the right grease, and fixing alignment can stop small problems from turning into big repairs.

Roller Bearings FAQ

What Are Roller Bearings?

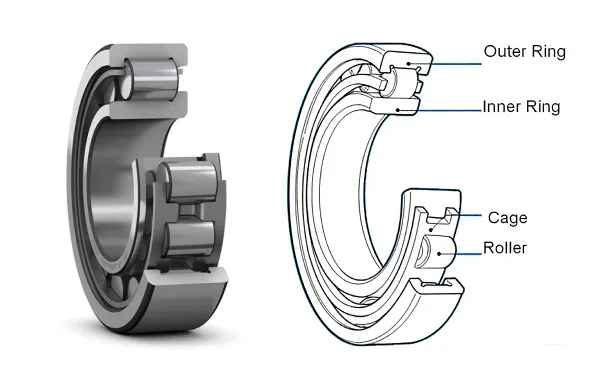

Roller bearings are in most heavy machines. They help machines move by lowering friction. Roller bearings support both spinning and sliding movements. They work even when machines carry heavy things or work in hard places. These parts help shafts and other pieces move well.

Here is what roller bearings do for you:

- They hold and help turn shafts so machines move better.

- They lower friction and handle both sideways and straight loads.

- They let parts get bigger or smaller with heat, so machines last longer.

They cut down friction, especially when you use cylindrical roller bearings for heavy things.

- They work well and are easy to fix because they all look the same.

You will find different roller bearings in big machines. Some common types are:

- Tapered roller bearings, which handle both sideways and straight loads.

- Spherical roller bearings, which can adjust if things are not lined up and carry heavy things.

- Needle roller bearings, which fit in small spaces but still hold a lot of weight.

- Cylindrical roller bearings, which hold big sideways loads.

- Slew bearings, which let cranes and diggers turn all the way around.

Roller bearings faq usually starts with these basics. This helps you see why these parts are important in your work.

Why Do Roller Bearings Fail?

Roller bearings can stop working for many reasons. The most common problems are not enough oil, dirt, and things not lined up right. Not enough oil causes about 80% of bearing problems. If you use the wrong oil or do not add oil often, you will hear noise, feel heat, and see the parts wear out too soon.

Dirt or water can also make bearings break. You might see rust, pits, or dents on the rolling parts. If things are not lined up or are too heavy, the bearings wear out faster. Sometimes, electricity or shaking can hurt the bearings too.

Here is a table showing the main causes of bearing failures:

| Cause of Roller Bearing Failure | Description | Approximate Contribution |

|---|---|---|

| Improper Lubrication | Bad oil choice, dirty oil, oil breaking down, or not adding oil at the right time. | ~80% |

| Contamination by Solid Particles | Dirt in the oil causing damage. | Significant |

| Corrosion due to Moisture | Water or acid in the oil or air causing rust. | Significant |

| Improper Mounting | Loads not balanced, things not lined up, or weight not spread out right. | ~5% |

| Inadequate Bearing Selection | Picking the wrong size or type of bearing. | ~10% |

| Overloading | Too much weight or sudden hits bending or marking the parts. | Included in indirect failures |

| Electrical Discharge Damage | Static or stray electricity making small pits. | Not quantified |

| Vibration-Induced Damage | Shaking while not moving making marks and dents. | Not quantified |

| Indirect Failures | Problems from how you use, move, store, or handle the bearings. | ~4% |

| Material Defects and Manufacturing Errors | Problems in the material or how it was made. | <1% |

You should look for early signs of bearing problems. Listen for grinding or clicking sounds. Feel if the bearing area is hot. Look for rust or other damage you can see. If you find these signs, you can stop bigger problems.

Need help with roller bearings faq or want expert advice? We at TFL Bearings can guide you and supply high-quality roller bearings for your needs.

Common Bearing Issues

Lubrication Failure

Lubrication failure is a big problem for roller bearings. If you do not use enough or the right kind, parts rub together. This makes heat, noise, and damage.

Symptoms of lubrication failure include:

- More friction causes extra wear and heat.

- The machine shakes more when running.

- The bearing gets hotter than it should.

- You hear loud squealing or grinding sounds.

- Seals leak and grease comes out.

- The grease looks dirty or has stuff in it.

You might see marks or grooves on the rollers. The cage inside can break if oil does not flow well.

Quick Fix:

Check if you have the right grease and enough of it. Grease works best for most roller bearings. It sticks and lasts longer. Use oil for machines that run fast or get hot. Always follow what the maker says about grease. Clean out old, dirty grease before adding new. If you see leaks, put in new seals.

Tip: Doing regular checks and using the right grease stops most problems. Keep grease clean and do not mix different types.

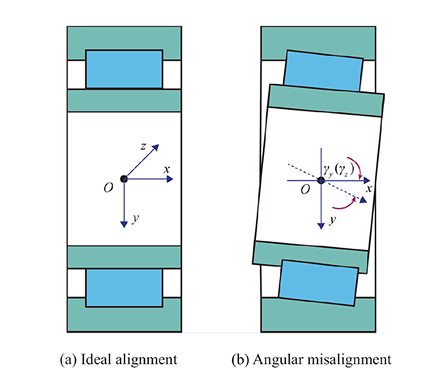

Misalignment

Misalignment happens when the shaft and housing are not straight. This puts stress on the rolling parts and makes bearings fail early.

Common causes of misalignment:

- Shafts are bent or housings are broken.

- Bad ways of putting in the bearing.

- Dirty or rough places where you mount the bearing.

- Using wrong tools or skipping checks.

Symptoms:

- Rollers and raceways wear unevenly.

- The machine shakes and makes more noise.

- Some spots on the bearing get very hot.

- The bearing does not last as long.

How to fix misalignment:

- Use laser tools to check if things line up.

- Look for hot spots with a heat camera.

- Watch for shaking to find problems early.

- Move the shaft and housing until they match up.

- Make sure the housing is strong and does not move.

Note: Put in roller bearings the right way with clean tools. Check often to catch problems before they get worse.

Contamination

Contamination is a top reason roller bearings break. Dirt, dust, water, or chemicals can get inside and mix with grease. This makes the grease rough and hurts the bearing.

Common contaminants:

- Dirt and dust from the air.

- Water from leaks or cleaning.

- Chemicals from other work nearby.

- Metal bits from other machine parts.

Effects of contamination on bearings:

- Rolling parts get scratched or pitted.

- Water causes rust and corrosion.

- Grease breaks down and stops working.

- Bearings break early and cost more to fix.

Quick Fix:

Check seals and covers for damage. Change any that are broken. Clean around the bearing before you work on it. Use good seals that fit and keep dirt out. If grease is dirty, clean the bearing and put in new grease or oil.

Do regular checks and use the right seals to stop dirt. Tools like vibration sensors help you find problems early.

Overloading

Overloaded bearings carry too much weight or get hit hard. This is a common problem that makes roller bearings wear out fast.

Signs of overloading:

- The machine is loud and shakes.

- Bearing parts have dents or are bent.

- You see flaking or cracks.

- The bearing gets too hot.

Too much or too little weight can both cause problems. Too much weight breaks parts. Too little makes them slide and wear unevenly.

How to fix overloading:

- Check if your bearings can handle the weight.

- Use more than one bearing for heavy loads.

- Try not to hit the machine hard.

- Watch for heat and noise to catch problems early.

Pick roller bearings that match the load. Check often to find overloads before they stop your machine.

Improper Installation

Improper installation often causes bearings to break. Mistakes when putting them in can damage them fast.

Common installation errors:

- Wrong fit makes the bearing slip.

- Heating the bearing too much.

- Not locking the bearing right.

- Not lining up the bearing.

- Using bad or rough tools.

Step-by-step for proper installation:

- Keep everything clean.

- Check the shaft and housing for dirt or damage.

- Use the right tools for the job.

- Push the bearing in gently and only on the right ring.

- Do not heat the bearing above 120°C.

- Use the right grease and check the seals.

- Lock the bearing the right way.

Tip: Always do what the maker says when installing. Use good grease and be careful to stop most problems.

Noise and Overheating

Noise and overheating mean something is wrong with roller bearings. These signs often show bigger problems like bad grease, misalignment, or too much weight.

Typical noise patterns:

- Grinding or rattling means dirt is inside.

- Screeching means not enough grease.

- Whining means the bearing needs more grease.

- Metal clanks mean parts are broken.

Temperature clues:

- Good bearings stay under 100°C.

- If it goes over 120°C or jumps between 90°C and 130°C, there is a problem.

How to fix noise and overheating:

- Use vibration tools to find the problem.

- Check if you have enough and good grease.

- Look for misalignment or too much weight.

- Change the bearing if it is badly worn.

Check your bearings often for heat and noise. Fixing problems early keeps your machines working well.

If you want help with roller bearings or need advice, TFL Bearings can help you. We have high-quality roller bearings and can show you how to do checks, use grease, and install bearings the right way to keep your machines running.

How to Fix Common Bearing Problems

Quick Fixes

You can fix roller bearings fast if you know what to look for. Use this troubleshooting guide to spot and fix problems before they get worse. Here are some quick solutions for the most common bearing problems:

- Use proper seals to keep dirt and water out. Clean the area before you work.

- Make sure all parts line up before you install the bearing. Use alignment tools for best results.

- Always use the right type and amount of lubricant. This is key for proper lubrication strategies.

- Follow the maker’s instructions when you install or replace a bearing.

- Do regular maintenance checks to catch problems early.

Essential tools for quick fixes include bearing pullers, induction heaters, alignment tools, lubrication tools, and safety gloves. These help you fix roller bearings safely and quickly.

Tip: If you hear noise, feel heat, or see leaks, stop the machine and check the bearing right away. Fixing small problems early helps prevent bearing failures.

Preventive Tips

Preventing bearing failures starts with regular maintenance. You need to keep roller bearings clean, well-lubricated, and properly installed. Here are steps to prevent bear problems and extend bearing life:

- Set up a lubrication program. Pick the right grease and keep it clean.

- Calibrate grease guns so you do not use too much or too little.

- Check bearings often for noise, heat, or vibration.

- Use seals and shields to block dirt and water.

- Train workers to spot early signs of trouble.

You should inspect and lubricate roller bearings based on their speed, size, and work conditions. Do not guess. Use charts or formulas to set the right schedule. Over-greasing can cause heat and damage, so always clean fittings before adding grease.

When to Replace

Sometimes, you cannot fix a bearing. You must replace it to avoid bigger problems. Replace roller bearings if:

- You see cracks, dents, or rust.

- The bearing makes loud or strange noises after you fix it.

- The bearing gets too hot or leaks grease even after maintenance.

- You find damage inside the bearing or after a hard impact.

- The bearing needs full disassembly to check or repair.

Here is a simple checklist for troubleshooting and deciding when to replace:

- Listen for noise and check for heat.

- Inspect for visible damage or leaks.

- Test with vibration and temperature tools.

- Check lubrication quality.

- If problems stay after you fix them, replace the bearing.

The average life of roller bearings depends on how you use them. For most machines, you can expect 8,000 to 20,000 hours of service.

If you need help with how to fix roller bearings or want expert advice, we at TFL Bearings can guide you. We offer high-quality solutions and support for preventing breakdowns through regular maintenance.

You can stop most roller bearings problems with regular care and fast fixes. Studies show that using the right grease as part of regular checks stops about 75% of failures. Taking care of your machines early helps you find problems like misalignment and contamination before they get worse. Some people think any grease or a quick clean is enough, but using the right steps and tools matters a lot. Watch for strange sounds, heat, or wear so you can fix roller bearings before bigger issues happen. If you want help or need good roller bearings, TFL Bearings can help keep your machines working well.

FAQ

How often should you check roller bearings?

You should inspect roller bearings every month. Look for noise, heat, or leaks. If your machine works in tough conditions, check more often. Regular checks help you find problems early.

What tools help you spot bearing problems?

You can use a stethoscope, a temperature gun, or a vibration sensor. These tools help you hear noise, check for heat, and feel for shaking. They make it easy to find issues before they get worse.

Can you mix different greases in one bearing?

No, you should not mix greases. Different greases can react and lose their power to protect. Always clean out old grease before adding new. Use the type your machine maker recommends.

What is the best way to store roller bearings?

Store roller bearings in a dry, clean place. Keep them in their original packaging. Lay them flat on shelves. Do not stack heavy items on top. This keeps them safe from dirt and damage.

Need help with roller bearings or want expert advice? We at TFL Bearings are ready to support you. Contact us for high-quality products and answers to your questions.