Choosing the right roller bearing suppliers helps your machines work well and last longer. Studies show that picking the wrong roller bearings causes about 10% of early bearing failures in machines. Bad supplier choices can cause big problems, like:

- Fake or poor-quality bearings

- More money and time spent on repairs

- No help from experts and mixed-up ways of working

- Paying more in the end, even if prices seem low

A step-by-step buying guide helps you stay away from these problems. If you use this checklist when you buy, you can feel sure about your choices and get good quality every time. Always use this method to keep your machines safe and get the most for your money when buying bearings.

Key Takeaways

- Pick roller bearings that match your machine’s needs. Think about the load type, where you will use them, and the size. This helps stop early problems and saves money.

- Only buy from suppliers who have lots of experience. Make sure they have the right certificates and good reviews. This helps you get good bearings and service you can trust.

- Look at the material standards and how they check quality. This helps you get strong bearings that work well, even in hard places.

- Choose suppliers who give good technical help and let you change things if needed. They should also have good service after you buy. This keeps your machines working well.

- Always check the price, how long delivery takes, and the warranty. Look at return rules before you buy. This helps you avoid extra costs and makes sure you get the right bearings on time.

Bearing Needs

Application

First, you need to know how you will use the bearings. Each machine has its own needs. Some machines must go fast. Others need to carry heavy things. Think about how the parts move and how much space you have.

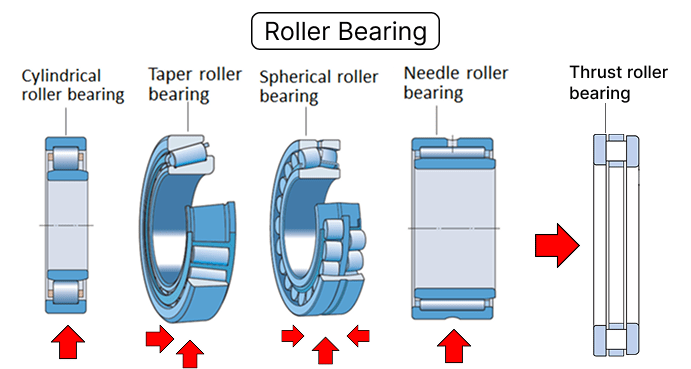

- Cylindrical roller bearings are good for motors and gearboxes. They can hold up heavy things that push out from the center.

- Tapered roller bearings are better if you need to hold up weight from the side and the center.

- Spherical roller bearings help if your machine gets bumped or is not lined up right.

- Needle roller bearings are best for small spaces.

- Thrust roller bearings work if you only need to hold up weight from the side.

Always pick the right bearing for your machine. This helps stop problems before they start.

Tip: If you do not know which bearing to use, ask a bearing expert. This can save you money and trouble.

Load & Environment

You need to check what kind of weight the bearing will hold. It can be from the side, the center, or both. Cylindrical roller bearings are strong for weight from the center. Tapered roller bearings can hold weight from both ways. Spherical roller bearings are good for heavy weight and when things are not lined up. The place where the bearing works is important too. Hot places, dust, water, or chemicals can hurt bearings. Sealed roller bearings keep out dirt and water. Fast machines need bearings that can handle heat and need oil or grease. Always pick the right bearing for the job and place. This keeps your machines working well.

| Roller Bearing Type | Load Type Capacity | Typical Applications |

|---|---|---|

| Cylindrical Roller Bearing | High radial load, limited axial load | Motors, gearboxes |

| Tapered Roller Bearing | Medium radial, high axial load | Wheel hubs, gear drives |

| Spherical Roller Bearing | High radial, medium axial load | Mining, railways, construction |

| Needle Roller Bearing | High radial, low axial load | Compact machinery, auto components |

| Thrust Roller Bearing | Low radial, high axial load | Turbines, transmissions |

Specifications

You should look at the details before you buy bearings. Check the size, inside and outside width, and how thick it is. These must fit your machine parts. The length and width of the rollers show how much weight it can hold. The cage keeps the rollers in the right place. You also need to check how exact the bearing is. Standards like ISO 492 and ABEC help you choose. A cylindrical roller bearing with a high rating lasts longer and works better. Always make sure the details match your machine. This helps you get the right bearing every time.

- Check what kind of weight and how much.

- Make sure it fits the speed and how exact it needs to be.

- Think about where it will work: hot, dusty, or wet places.

- Look at rules like ISO, ABEC, and JIS.

- Ask an expert if you need something special.

Supplier Credibility

You need to check if roller bearing suppliers are trustworthy. Good suppliers help your machines work well and save you money. Use this checklist to pick only the best suppliers.

Experience

Pick suppliers who have worked with bearings for many years. They know how to fix problems and give good advice. They understand different machines and help you choose the right bearings. Top bearing manufacturers follow rules like ISO or ABEC. This means their bearings last longer and work better. Good suppliers also give you help when you need it. This keeps your machines running without trouble.

- Find out how long the supplier has sold bearings.

- Ask if they know about your type of machine.

- Make sure they use quality rules for their products.

Working with experienced suppliers helps your machines work better. You get bearings that fit your needs and are high quality.

Certifications

Certifications show that a supplier cares about making good products. Good suppliers have certificates from trusted groups. These papers prove they follow strict rules when making bearings. Look for these common certificates:

| Certification Type | Description / Industry Relevance |

|---|---|

| ISO9001 | General quality management standard for all manufacturers, including roller bearing suppliers. |

| AS9100 / EN9100 | Aerospace quality standards, important for top bearing manufacturers in defense and aviation. |

| Nadcap | Covers special processes like heat treating and coatings, ensuring high quality. |

| IRIS | Relevant for rail and transportation bearing suppliers. |

| FOCA | Often used for aerospace components. |

| Corporate Certifications | Given by major companies like Boeing or Raytheon, showing strict quality compliance. |

Always ask to see these certificates before you buy. This helps you avoid fake or bad bearings.

Reviews

Customer reviews tell you what other people think about the supplier. Read reviews to learn about problems like bad lubrication or noisy bearings. These problems can cost you more money and time. Good suppliers have happy customers who talk about fast delivery and good service. You can also ask for names of other customers. This helps you see if the supplier keeps their promises.

- Look for reviews about quality, delivery, and service.

- Watch for the same problems in many reviews.

- Pick suppliers with a good name and happy buyers.

Tip: Good suppliers will show you their reviews and references. If you cannot find any, look for another supplier.

By checking experience, certificates, and reviews, you make sure you pick good suppliers. This keeps your machines safe and helps your business.

Product Quality

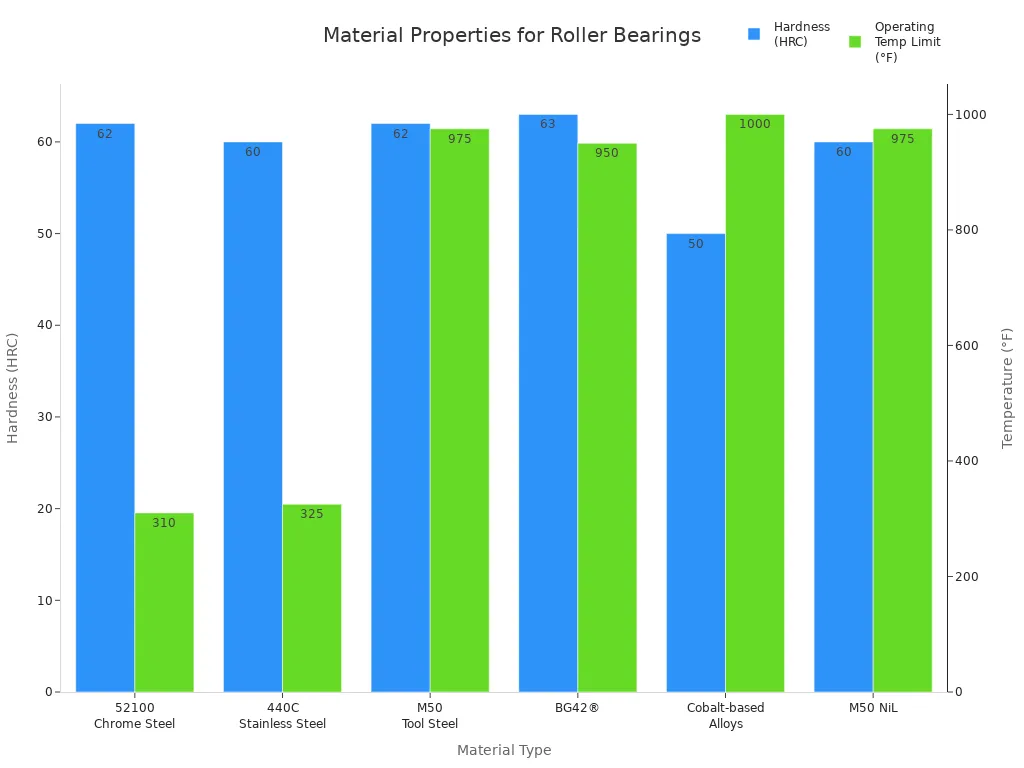

Material Standards

You should check the material standards before buying roller bearings. Good materials help bearings last longer and work better. The best bearing suppliers use strong steel and alloys. These materials follow strict rules and special melting steps. This removes bad stuff and makes the bearings strong. You get better wear resistance and more strength. The table below lists common materials and their features:

| Material Type | Industry Specification | Melting Method | Key Features and Advantages | Hardness (HRC) | Operating Temperature Limit | Heat Treatment Attributes |

|---|---|---|---|---|---|---|

| 52100 Chrome Steel | AMS 6440 | Vacuum Degassed | Good wear and fatigue properties | 60-64 | 310 °F | Standard heat treatment for durability |

| 440C Stainless Steel | AMS 5880 | Air Melt or Vacuum Degassed | Corrosion resistance, good wear properties | 58-62 | 325 °F | Thermal stability with corrosion resistance |

| M50 Tool Steel | AMS 6491 | Vacuum Induction Melted / Vacuum Arc Remelted | High temperature capabilities, excellent fatigue properties | 60-64 | 975 °F | High thermal stability |

| BG42® | AMS 5749 | Vacuum Induction Melted / Vacuum Arc Remelted | Corrosion resistance, high temperature capabilities | 61-65 | 950 °F | Excellent wear properties, high thermal stability |

| Cobalt-based Alloys | AMS 5759 | Consumable Electrode Vacuum Melted | Chemical resistance, high temperature capabilities | 50 (min) | 1000 °F | Good thermal stability, low hardness reduction at elevated temperatures |

| M50 NiL | AMS 6278 | Vacuum Induction Melted / Vacuum Arc Remelted | Carburized, high fracture toughness, accommodates high hoop stresses and cyclic loading | Case: 60 (min) | 975 °F | High fracture toughness core |

You can see how hard and heat-resistant these materials are in this chart:

High-quality roller bearings use these materials for better performance. They work well even in tough places. Always ask suppliers about the material standards they use.

Quality Control

You want bearings that work well every time you use them. The best suppliers use strong quality control at each step. They start with pure raw materials and test them. Each part is forged, shaped, and heat treated. Machines cut and grind the parts to the right size. Workers check the hardness and finish of every piece. The process includes:

- Testing raw materials for the right mix.

- Forging and shaping for strength.

- CNC turning for perfect shapes.

- Heat treating for hardness.

- Checking hardness and size.

- Grinding and finishing for smoothness.

- Final checks for fit and function.

Suppliers use special tools to find mistakes fast. They track every step and fix problems quickly. You get bearings that meet ISO 9001:2015 and CE standards. This means fewer breakdowns and longer machine life. Top suppliers train their teams and keep getting better. You can trust their bearings to keep your machines running.

Note: Always ask about the supplier’s quality control steps. This helps you avoid costly failures.

Product Range

A wide product range helps you find the right roller bearings. Top suppliers offer many types, sizes, and designs. You can pick from ball bearings, roller bearings, and special types. The table below shows common types and their uses:

| Bearing Type | Description & Use Case | Impact on Purchasing Decisions |

|---|---|---|

| Ball Bearings | Versatile, used in high-speed applications with low friction. | Broad applicability makes them a common choice for general purposes. |

| Roller Bearings | Designed for heavier loads; includes cylindrical, spherical, and tapered types. | Variety allows matching specific load and speed requirements, improving reliability and performance. |

| Cylindrical Roller Bearings | Handle high radial loads and high speeds; used in electric motors, gearboxes, pumps. | Preferred when high radial load capacity and speed are critical. |

| Tapered Roller Bearings | Handle both radial and axial loads; common in automotive, agricultural, and construction machinery. | Enables selection for combined load scenarios, enhancing durability and operational efficiency. |

| Spherical Roller Bearings | Accommodate misalignment and heavy loads; used in mining, material handling, paper mills. | Suitable for harsh environments and misalignment, influencing buyers needing robust solutions. |

| Plain Bearings | Simple, cost-effective, high load capacity; good for oscillatory or low-speed applications. | Cost-effective option for specific low-speed or oscillatory needs. |

| Thrust Bearings | Designed to handle axial loads alone; available in ball and roller types. | Critical for applications with predominant axial forces, guiding specialized purchasing. |

| Needle Roller Bearings | Thin rollers for limited space but high load capacity; used in compact automotive transmissions. | Space constraints combined with load needs drive selection of these specialized bearings. |

You get more choices and better solutions for your machines. This variety lets you match the right bearings to your needs. Good suppliers help you pick the best option, saving you time and money. Their focus on quality and support makes buying easier and better.

Support & Services

Technical Support

You need good technical support when buying bearings. Good suppliers have experts who can visit your site. They help fix problems quickly. They offer services like installation and inspection. They also give training to your team. You get digital tools like online catalogs and apps. These tools help you pick the right bearings. Engineering support helps you design special solutions. Suppliers help manage your spare parts and inventory. This means you always have bearings when you need them. Training programs teach you how to install and care for bearings. This helps your machines last longer.

| Type of Technical Support | Description & Value to Industrial Buyers |

|---|---|

| Industry Expert Assistance | Experts come to your site and help find problems. They help your machines work better and stop breakdowns. |

| Maintenance Services | They help with putting in bearings, checking them, and fixing them. They also teach you the best ways to care for bearings. |

| Digital Tools | You get online catalogs, tools for checking bearing life, and apps. These help you choose and use bearings the right way. |

| Engineering Support | You can get help making special bearings for your machines. This is good for special jobs. |

| Inventory & Spares Management | Suppliers help you keep enough spare bearings. This stops your machines from stopping because you ran out. |

| Training Programs | You and your team learn how to put in and care for bearings. This helps stop mistakes and keeps machines working. |

Tip: Pick suppliers who give expert help and easy digital tools. This support helps you use your bearings better.

Customization

Sometimes, regular bearings do not work for your machines. Customization lets you get bearings made just for you. Suppliers can make bearings in special sizes or with coatings. These coatings help with heat, chemicals, or heavy loads. Some jobs, like in airplanes or food factories, need special bearings. Custom bearings help you follow these rules and keep machines safe. You can also ask for changes like special oils or sensors. These changes help your bearings work better. Custom bearings may cost more and take longer to get. But they help your machines work better and last longer.

You work with the supplier’s engineers to make the right bearings. Working together helps you solve hard problems and get the best results.

After-Sales

After you buy bearings, you still need good service. The best suppliers help you for as long as you use the bearings. You get help from real people, not just a call center. Many suppliers give 24/7 support and fast shipping. You can return bearings within 50 days if they do not fit. Some suppliers give up to 24 months of warranty. You can ask for special bearings if you need them. They help you find hard-to-get bearings and ship them to you.

- Help for special projects

- Fast returns and warranty help

- Real people answer your questions

- Same-day shipping and quick sales

- Help with finding and keeping bearings

Note: Good after-sales service means you always have the bearings and help you need. This keeps your machines working and your business strong.

Pricing & Delivery

Transparent Pricing

You need to know the real price when you buy bearings. Good suppliers tell you all the costs right away. They do not hide fees or add extra charges later. You can see the price for each bearing and shipping. You also see the cost for any extra services. This helps you plan your money and avoid problems. When you look at prices, check what is included. Some suppliers give discounts if you buy a lot or sign a long contract. Ask about these deals to save money. Clear prices help you trust the supplier and make smart choices.

Tip: Always ask for a full price list before you buy. This keeps you safe from hidden costs and helps you compare suppliers.

Shipping Options

You want your bearings to arrive fast and safe. The best suppliers give you different ways to ship. You can pick standard, express, or even same-day delivery. Some suppliers let you track your order, so you always know where it is. If you need special boxes or careful handling, ask your supplier. Good shipping choices help your business run well and stop delays. Reliable delivery keeps your machines working and saves you money.

- Standard shipping: Good for most orders and costs less.

- Express shipping: Use this if you need bearings fast.

- Same-day or next-day: Best for emergencies.

- Tracking: Lets you see your order at every step.

Lead Times

Lead time means how long it takes to get your bearings. Fast lead times help your business and keep your work on track. If the bearings are in stock, you get them in 1-3 days. This quick delivery keeps your machines running. If the bearings must be made, it can take 3-6 weeks. Shipping adds more time, from 3 to 14 days, depending on where you are and how you ship. Customs or other problems can make it take longer.

Here is a table to help you see lead times:

| Lead Time Component | Duration | Impact on Production Schedules |

|---|---|---|

| In-stock delivery | 1-3 business days | Minimal impact; quick integration into production |

| Manufacturing lead time | 3-6 weeks | Possible delay; depends on order and complexity |

| Shipping time | 3-14 business days | Adds variability; depends on method and location |

| Additional factors | Varies | Customs or disruptions can cause unpredictable delays |

You should talk to your supplier about lead times before you order. Good planning helps you avoid stops in your work and keeps your business running smoothly.

Warranty & Returns

Knowing about warranty and return rules helps protect your money. It also makes sure you get good roller bearings. Good suppliers stand by their products. They give clear answers if something goes wrong.

Warranty Terms

Always check the warranty before you buy roller bearings. Top suppliers like SKF give a 12-month warranty for most bearings. This covers many types, like deep groove ball bearings and tapered roller bearings. Spherical roller bearings, thrust bearings, and angular contact ball bearings are also included. Some suppliers give longer warranties for special bearings. For example, some motor bearings have a 5-year warranty. You must install, care for, and check your bearings the right way to keep your warranty. Good suppliers give you clear papers and make claims easy. They also help in different languages, so you know your rights. If you buy expensive or custom bearings, you might get a longer warranty. This shows the supplier cares about quality.

- Most bearings have a 12-month warranty.

- Special bearings can have up to 5 years.

- Many bearing types are covered.

- You must install and care for them right.

- You get clear papers and easy claims.

Return Policy

A good return policy means the supplier trusts their bearings. Look for suppliers who let you return bearings if they are not right. You can also return them if you got the wrong ones. Most good suppliers let you return items in 30 to 50 days. The steps should be easy and not take much time. Good suppliers check returned bearings to learn and get better. A fair return policy helps you feel safe and makes sure you get what you paid for.

Tip: Always ask how long you have to return things and if there are any extra fees. This helps you avoid problems and keeps you focused on getting good bearings.

Dispute Resolution

Sometimes, problems happen even with good suppliers. You need a simple way to fix these problems fast and fair. Good dispute rules help protect you and keep quality high. The best contracts use steps to solve problems:

| Step | What Happens |

|---|---|

| Negotiation | Both sides talk and try to fix the problem in a set time. |

| Mediation | A neutral person helps both sides agree. |

| Arbitration | An outside group decides if the first steps do not work. |

| Performance Review | Both sides meet to talk about ongoing problems. |

| Penalty Enforcement | There are penalties if deadlines are missed or quality is bad. |

Make sure the dispute steps are clear, easy, and fair. This helps keep costs low and makes sure you get good roller bearings from your supplier.

Purchasing Guide Summary

Checklist Review

You need to check each step when buying roller bearings. This helps you pick the best ones for your machines. Use this checklist to help you decide:

- Bearings should cut down on friction and heat. This helps them last longer.

- Make sure the load is spread out evenly. This stops too much stress on the edges.

- Look for a smooth finish on the surface. This helps oil cover the bearing.

- Pick bearings that make less noise and shake less.

- Choose bearings that work well with heavy loads and fast speeds. These are good for places like farms or mines.

- Seals are important. They keep out dirt, water, and other things that can hurt the bearing.

Here is a table to help you remember the main things to check before you buy:

| Checklist Point | Description |

|---|---|

| Dimensions | The size must fit your machine. Check the hole, outside, and width. |

| Operating Specifications | Look at the speed and how much weight it can hold from the sides and ends. |

| Materials | Use strong steel that is made to last a long time. |

| Bearing Setting | Adjust how tight or loose the bearing is, especially for tapered roller bearings. |

| Sealing | Make sure seals keep out dust and water. This helps bearings last longer. |

Tip: Always check these things before you finish buying. This helps you save money and keeps your machines working well.

Next Steps

After you finish your checklist, follow these steps to get the best use from your roller bearings:

- Keep your work area and bearings clean. This stops dirt from getting in.

- Do not wash new bearings. They already have oil on them.

- Store bearings in their box in a dry, quiet place.

- Handle bearings gently. Do not drop them.

- Use clean tools made for putting in and taking out bearings.

- Put in seals the right way to keep out dirt.

- Check the shaft and housing to make sure they are clean and the right size.

- Start putting in the bearing at the rounded edge.

- Use the oil or grease the maker says is best.

- Only use the right kind of oil or grease for your job.

- Make sure the outer part of the bearing sits flat in the hole.

- Never hit the bearing or its parts with a hammer.

- Press the bearing in with even pressure.

- Listen for strange sounds or shaking after you put it in.

- Use the same kind of bearing when you replace one.

- Check the bearing again as the maker tells you.

- Always follow safety rules and wear safety gear when working.

You should also look at your roller bearings for damage before using them again. Turn small bearings to see if they move smoothly. Look for cracks, rust, or pieces coming off. Change any bearing that looks damaged. Careful handling and checking often help you get the most out of your bearings.

When you use this buying guide, you keep your machines safe. You also save money by making smart choices. A checklist helps you pick the right roller bearings. This stops your machines from breaking down and costing more. Good bearings last longer and need less fixing. TFL Bearings is a trusted place to buy roller bearings. They give good prices and ship your order quickly. You get help when you buy and after you buy. Many big companies trust TFL Bearings for their roller bearings. They offer special solutions if you need them. Contact us today so we can help you choose the best roller bearings for your needs.

FAQ

What should you check before purchasing bearings online?

Check the bearing size and type before you buy. Make sure the load rating matches your machine. Look at the supplier’s certificates and read customer reviews. Good suppliers give clear details and help you if needed. This helps you pick the right part and avoid mistakes.

How do you know if a roller bearing supplier is trustworthy?

See how long the supplier has worked in the industry. Check if they have certificates and good customer feedback. Trustworthy suppliers show papers and answer your questions fast. They give technical help and explain their warranty rules. This makes you feel sure about your order.

Why do material standards matter for roller bearings?

Material standards help bearings last longer and work better. Good steel or alloys stop wear and handle heat well. Ask your supplier what materials they use. This helps you avoid early breakdowns and saves money.

What after-sales support should you expect from a supplier?

You should get help with putting in bearings and fixing problems. Good suppliers answer quickly and have easy return rules. They give advice and offer new parts if needed. This support keeps your machines working well.

Can you return bearings if they do not fit your machine?

Most good suppliers let you return bearings in 30 to 50 days. The bearings must be unused and in the original box. Always read the return rules before you buy. This helps you avoid trouble later.