Many industries use plastic roller bearings for tough jobs. Engineers pick these parts for many reasons:

- They are lighter than metal parts, so they use less energy and put less strain on machines.

- They do not rust, so they work well in wet or chemical places.

- They are quiet, help belts last longer, and need less care because they can oil themselves.

- Careful making of these parts means they work well and do not break easily.

We at TFL Bearings want you to see how our products can help your work.

Key Takeaways

- Plastic roller bearings are light. They do not rust. They resist chemicals. They need little care. This helps machines last longer. It also helps them work better.

- These bearings work in many industries. They are used in cars, food, medicine, electronics, and marine fields. They are quiet. They are clean. They can oil themselves.

- Picking the right plastic bearing is important. You must think about load and speed. You must look at the environment and materials. Experts can help you choose the best one.

- Hybrid and composite plastic bearings are stronger. They can go faster. They work better in hard places.

- Using plastic roller bearings saves energy. It lowers costs. It helps make cleaner and smarter machines for the future.

What Are Plastic Roller Bearings?

Structure and Materials

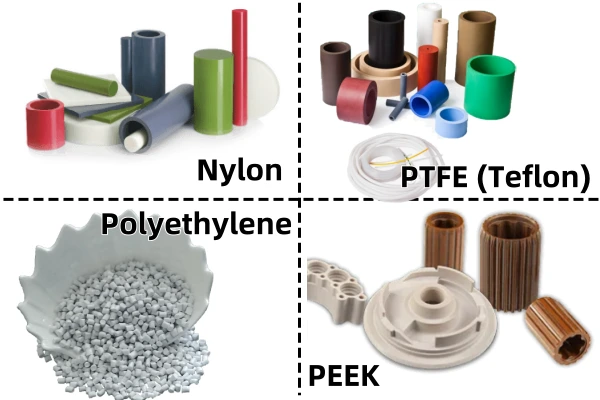

Plastic roller bearings are made from special plastics. These plastics are strong and work well in many factories. Makers use materials like PEEK, PTFE, and tough thermoplastics. These materials have special features. Some bearings have solid oil inside and strong fibers. This helps them last longer and slide smoothly. The bearing has a plastic ring on the outside. Inside, there is a cage made of plastic or stainless steel. The rolling parts can be plastic, glass, or ceramic. This design lets the bearing come in many shapes and sizes. It can fit into small spaces or special machines.

Note: The material and shape of the bearing change how it works. This is very important in places with water, chemicals, or where things must stay clean.

The table below shows how plastic roller bearings and metal roller bearings are different:

| Performance Aspect | Plastic Roller Bearings | Metal Roller Bearings |

|---|---|---|

| Material Composition | Self-lubricating polymer with embedded lubricants | Steel or bronze alloys |

| Lubrication Requirement | Self-lubricating, no external lubrication needed | Requires regular lubrication |

| Corrosion Resistance | High; resists moisture, chemicals, and corrosion | Susceptible to corrosion and contamination |

| Maintenance Needs | Minimal; ‘fit-and-forget’ | Higher; needs regular maintenance |

| Load Capacity | Lower compared to metal | Higher, suitable for heavy loads |

| Coefficient of Friction | Consistently low | Can increase over time |

| Suitability for Harsh Environments | Excellent; ideal for food, wash-down, chemical use | Limited; may need special coatings |

| Cost and Downtime | Reduces costs and downtime | Higher cost and more downtime |

| Temperature Tolerance | Wide range, up to ~500°F | Limited, may need special lubricants |

| Sanitation Compliance | Meets food and medical standards | Not as sanitary |

Key Properties

Plastic roller bearings have many good features. They are light, so machines are easier to move. This helps save energy. They do not need extra oil or grease. This keeps them clean and easy to care for. These bearings do not rust from water or chemicals. This makes them great for food, medical, and sea jobs.

- Plastic roller bearings do not get damaged by strong chemicals.

- Their light weight makes machines lighter and saves power.

- They make less noise because they stop shaking.

- You do not need to add oil often because they have oil inside.

- Some plastics can hold heavy loads like bronze, but most work best with lighter jobs.

- Plastics get bigger when hot, so engineers must plan for this.

- Metal bearings are better for fast machines because they handle heat and fit tighter.

- PEEK and PTFE bearings have oil inside and are strong, but they cannot hold as much weight as metal.

Tip: If you need bearings that do not rust, are quiet, and need little care, plastic roller bearings are a smart choice.

We at TFL Bearings help people pick the best plastic roller bearings. We make sure they work well and last a long time.

Advantages of Plastic Roller Bearings

Corrosion and Chemical Resistance

Plastic roller bearings do not rust or get damaged by chemicals. Many companies use them in wet or tough places. These bearings keep working even with water or strong cleaners. Metal bearings can stop working in these spots, but PEEK and PTFE stay strong. This is why they are used for food, medical, and sea jobs.

Lightweight and Low Inertia

Plastic roller bearings are much lighter than metal ones.

- They can be five times lighter than steel bearings.

- Lighter bearings help machines use less energy.

- Low inertia lets them turn faster and smoother.

- One-piece plastic parts make them even lighter.

Light bearings help robots move fast and make machines easy to use. The good strength and low weight give engineers more ways to design.

Non-Magnetic and Electrical Insulation

Plastic roller bearings do not let electricity pass through.

- Plastics like Nylon, PPS, and PEEK block electricity well.

- These plastics keep machines safe from electric harm.

- They do not soak up much water, so they keep their shape.

- Many plastics meet tough safety rules for electricity.

Tests show plastic bearings stop electric damage that hurts metal ones. This makes them good for electronics, medical tools, and places with strong magnets.

Self-Lubrication and Clean Operation

Plastic roller bearings often have oil inside them.

Bearings with oil inside save time and money because you do not need to add oil often.

Many companies save a lot of money with these bearings. For example, one company made their bearings last six times longer and spent much less money. Factories with many bearings save thousands of dollars each year on work and repairs. Clean bearings also mean no oil leaks, which is very important for food and medical jobs.

Design Flexibility

Plastic roller bearings can be made in many shapes and sizes.

- Engineers can make special shapes for their needs.

- AI helps make better designs for the bearings.

- Smart sensors can be put inside to watch how they work.

- These bearings help make cheap robots and machines.

Plastic lets parts be made together, so machines have fewer pieces and weigh less. This helps new ideas for smart factories and green production.

At TFL Bearings, we help you pick the best plastic roller bearings. We give advice and custom choices to make your machines better and save you money.

Application Fields of Plastic Roller Bearings

Plastic roller bearings are used in many industries today. They are special because they do not rust, are light, and can oil themselves. This makes them a top choice for many jobs. Here are some main industries that use these bearings.

Automotive Industry

Car makers use plastic roller bearings for many reasons. These bearings help make cars lighter. Lighter cars use less gas and make less pollution. The smooth design helps cars run better and saves energy. New plastics make strong bearings for tough car parts. Electric and hybrid cars need bearings that work at high speeds and heat. Car makers like that these bearings do not rust and need little care. This helps cars last longer and work well. Designers put these bearings in steering, dashboards, and motors. They help cars run quietly and last a long time.

Food and Beverage Processing

Food factories must be very clean and safe. Plastic roller bearings help keep things clean. They do not soak up water, so germs cannot grow. Their light color makes it easy to spot if a piece breaks off. These bearings have oil inside, so no extra oil is needed. This keeps food safe from oil leaks. They can handle strong cleaners and hot steam. They also meet food safety rules like FDA and NSF. These bearings are used in machines that move, pack, and fill food. They help keep lines clean and stop machines from breaking down.

Medical and Pharmaceutical Equipment

Medical tools need to be clean and work well. Plastic roller bearings are good for this. They do not rust, even with water or cleaning chemicals. They are light, so machines are easy to move. The oil inside means no messy oil is needed. They last a long time, even when washed often. They meet health rules to stop germs. These bearings do not mess with magnets, so they are safe for medical devices. They last long and need little care, which saves money for hospitals.

Electronics and Office Machinery

Electronics and office machines need quiet, steady parts. Plastic roller bearings are not magnetic, so they protect circuits. They stop static and electric problems. They move smoothly, which helps printers and scanners work well. Their light weight helps make small, smart machines. Makers use them in printers, copiers, and ATMs. This helps paper move quietly and stops jams.

Material Handling and Conveyors

Factories use plastic roller bearings in moving systems. These bearings oil themselves, so no extra care is needed. The oil inside helps them last a long time. They cost less than metal bearings, especially when used a lot. They do not rust, even in wet or dusty places. Their light weight makes them easy to put in and move. These features help machines work better and stop delays in factories.

Marine and Underwater Applications

Boats and underwater machines need special bearings. Plastic roller bearings work well in water. They do not rust in saltwater. They oil themselves, so no extra oil is needed. They are light, which helps boats and robots move easily. They need little care and last a long time. These bearings are used in underwater robots, pumps, and boat parts. They keep working well with little fixing needed.

| Feature | Plastic Roller Bearings | Traditional Metal Bearings |

|---|---|---|

| Corrosion Resistance | High | Low |

| Lubrication | Self-lubricating | Requires frequent lubrication |

| Weight | Light | Heavy |

| Maintenance | Minimal | Frequent |

| Suitability for Saltwater | Excellent | Limited |

Packaging and Industrial Processing

Packing and factory machines use plastic roller bearings. They do not need extra oil, so there is less risk of dirt. They do not get dirty or rusty, so they last longer. Their life is easy to predict, so workers know when to check them. They meet food safety rules, so they are safe for packing food. They are strong and last a long time, which saves money. These bearings help machines run quietly and smoothly.

Security and Surveillance Equipment

Cameras and security tools need to move quietly and work well. Plastic roller bearings help cameras turn smoothly. They do not rust, so they work outside too. They make less noise and shake less, which helps cameras stay hidden. No oil is needed, so they need less fixing. They are not magnetic, so they protect electronics. These features help cameras and sensors work right and last longer.

Entertainment and Leisure Equipment

Fun machines like gym gear and rides use plastic roller bearings. These bearings can hold weight from different sides and lower friction. They need little care and help machines run quietly. The oil inside stops stains and keeps things quiet. This is good for gyms, playgrounds, and fun machines.

At TFL Bearings, we help you pick the best plastic roller bearings for your needs. We give advice and make special choices to keep your machines working well and save you money.

Selection Criteria for Plastic Roller Bearings

Load and Speed Considerations

Engineers need to pick the right bearing for each job. Heavy loads need strong bearings that last a long time. Fast machines need materials that do not change shape from heat. Some plastics work well with medium weights. Others are better for light, fast-moving parts. Designers may use bigger balls or two rows to spread out the force. When machines move fast, low friction and low inertia are very important. This helps save energy and makes machines last longer.

Tip: Always look at the highest load and speed a bearing can handle before you choose one.

Environmental and Regulatory Factors

Where the bearing is used changes what kind you need. Wet or chemical places need bearings that do not rust and have seals. Dusty places need sealed bearings or air to keep dirt out. Very hot or cold places need plastics and oils that work in those temperatures. Rules are also important. For example, new laws in Europe will soon stop many PFAS chemicals. This means companies must use new materials that still work well and follow the rules. Now, some companies make bearings without PFAS or PTFE to meet these new laws and help the planet.

- If there are liquids, use seals and materials that do not rust.

- If there is dust, use sealed bearings or air to keep dirt out.

- If it is very hot or cold, pick plastics and oils made for those temperatures.

Material and Manufacturing Choices

The material you pick changes how long the bearing lasts and how strong it is. Some plastics with crystals last longer and fight chemicals better than others. Some jobs need plastics with fibers to make them stronger. How the bearing is made also matters. Injection molding is good for making lots of bearings and lets you make special shapes. CNC machining is better for small amounts or custom parts. Engineers must think about cost, how well it works, and how many they need when choosing.

Note: Picking the right material and way to make the bearing can make it work better and last longer.

At TFL Bearings, we help people find the best bearing for their needs. Our team gives advice and special choices so every job gets the right part.

Limitations and Solutions

Load and Speed Limitations

Plastic bearings are useful, but they have some limits. These limits show up when machines move fast or carry heavy things. Engineers see a few main problems:

- Plastic bearings cannot run over 5,000 RPM for long.

Plastic can change shape faster than metal

with heat and speed.- Metal bearings are harder and bend less, so they work better with big loads and fast speeds.

Because of these things, engineers sometimes need to make plastic bearings stronger and tougher.

Hybrid and Composite Solutions

To fix these problems, experts made hybrid and composite bearings. These mix different materials to work better. The table below shows how adding strong stuff to plastics helps them:

| Composite Type | Reinforcement | Test Method | Load Conditions (N) | Speed (RPM) | Key Findings |

|---|---|---|---|---|---|

| Pure PTFE | None | Ball-on-disc | 25, 50, 75 | 800 | Not very strong, wears out fast, but slides easily because it has oil inside. |

| PTFE + 25% Carbon (CR25) | Carbon filler | Ball-on-disc | 25, 50, 75 | 800 | Lasts longer and works better with more weight and speed. |

Engineers also use hybrid ball bearings with polymer rings and cages. The balls can be steel, glass, or special plastics. These bearings have some good points:

- They do not need oil, so there are no leaks.

- The soft feel of polymers helps stop shaking.

- They are good for clean places where oil leaks are bad.

- They are not for the heaviest jobs, but they help with speed and oil problems in plastic bearings.

Note: Composite and hybrid bearings help them last longer and work better, especially where rust and cleanliness are important.

At TFL Bearings, we help people pick the best bearing for their job. We give advice and special choices so machines work well every time.

Plastic roller bearings help many industries like cars, food, medicine, and electronics. They last a long time and work quietly. They do not need much fixing or care.

In the future, more people will want parts that are light and do not rust. This is important for electric cars and smart factories.

- Companies pick these bearings because they oil themselves. They also save money and can be made in many shapes.

- Asia-Pacific and Europe are using more of these bearings as technology gets better and people care more about the planet.

| Series | Application Type | Maintenance Benefit | Noise Level |

|---|---|---|---|

| 1000/2000 | Gravity, slow-speed | No extra oil needed | Runs more quietly |

We at TFL Bearings want you to talk to our experts. We can help you find the right bearing for your job.

FAQ

What industries use plastic roller bearings the most?

Plastic roller bearings are used in many fields. They are found in cars, food factories, hospitals, electronics, and boats. Engineers like them because they are light and do not rust. They also need little care.

How do plastic roller bearings handle harsh chemicals?

Engineers pick special plastics that do not break from strong chemicals. These plastics can stand up to acids and cleaners. So, these bearings work well in chemical plants and food factories.

Can plastic roller bearings work in wet or underwater environments?

Yes, they can. Plastic roller bearings do not rust in water. They work well in pools, dishwashers, and on boats.

Do plastic roller bearings need regular lubrication?

No, they do not. Most plastic roller bearings have oil inside them. This means you do not need to add oil often. It also keeps things clean.

How do engineers choose the right plastic roller bearing?

Engineers look at how much weight and speed the bearing needs. They also check the heat and where it will be used. Then, they pick the best material and shape for the job.

Tip: Always ask experts to help you choose the right bearing.

We at TFL Bearings can help you pick the best plastic roller bearing. Contact us for advice and special choices.