Introduction: The Importance of Miniature Bearings in Modern Machinery

In modern industries, where efficiency, speed, and compactness define technological innovation, the demand for high-quality miniature bearings continues to grow. Among the most critical components used in precision machinery are miniature angular contact ball bearings, which combine a small size with remarkable performance capabilities.

These bearings are designed to support both radial and axial loads simultaneously while maintaining stability under high-speed operations. At SDTFL Bearing, we specialize in manufacturing advanced miniature angular contact ball bearings that meet the highest standards of precision engineering and long-term reliability.

What Are Miniature Angular Contact Ball Bearings

Miniature angular contact ball bearings are specialized rolling bearings designed to manage combined loads, including both radial and axial forces. The inner and outer ring raceways are positioned at an angle to each other, enabling the bearing to support loads in one direction or both, depending on the design.

Their compact size and lightweight construction make them ideal for applications where space is limited but performance requirements are high. From micro-motors and medical instruments to robotics and industrial automation systems, these bearings play a vital role in ensuring smooth, precise, and efficient motion.

Design and Structure of Miniature Angular Contact Ball Bearings

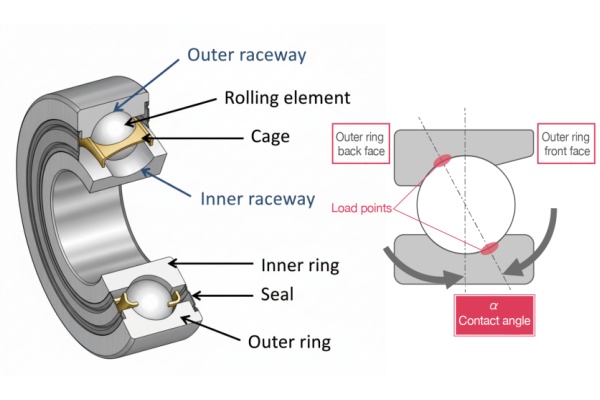

The performance of miniature angular contact bearings lies in their unique design. Each bearing consists of an inner ring, outer ring, cage, and rolling elements (balls) arranged in a way that allows angular contact between the raceways.

Key Design Features

- Angular Contact Geometry

The raceways of the inner and outer rings are offset to form an angle, typically ranging from 15 to 40 degrees. This design allows the bearing to carry axial loads in one direction while maintaining stability at high speeds. - High-Grade Materials

SDTFL uses high-quality bearing steel and stainless steel to ensure corrosion resistance, durability, and consistent performance in various operating conditions. - Precision Tolerances

The bearings are manufactured to tight dimensional tolerances, ensuring low vibration and minimal noise during operation. - Lubrication Options

Depending on the application, the bearings can be supplied with grease or oil lubrication, ensuring smooth motion and reduced friction. - Cage Design

The cages are often made from brass, steel, or polymer materials, each offering specific advantages in terms of speed, weight, and resistance to wear.

Working Principle

The angular contact design allows the bearing to distribute loads efficiently between the inner and outer rings. When axial loads are applied, the contact angle ensures even force distribution, reducing stress and prolonging the lifespan of the bearing.

In applications with high rotational speeds, the design minimizes friction and heat generation, maintaining consistent performance under demanding conditions.

Advantages of Miniature Angular Contact Ball Bearings

- Compact Design

The small size allows these bearings to be integrated into limited spaces without compromising performance. - High-Speed Capability

Designed for smooth rotation, they can operate at extremely high speeds while maintaining accuracy. - Excellent Load Handling

The angular contact configuration supports both radial and axial loads, making it ideal for complex mechanical systems. - Long Service Life

Precision materials and advanced lubrication reduce wear and extend the operational lifespan. - Low Noise and Vibration

Precision manufacturing ensures quiet and stable operation, crucial for sensitive or high-performance devices. - Versatility

Suitable for a wide range of industries, from aerospace and robotics to medical equipment and electronics.

Applications of Miniature Angular Contact Ball Bearings

Due to their efficiency and versatility, these bearings are widely used in numerous applications:

- Robotics and Automation Systems – Ensures smooth, precise motion in robotic arms and servo motors.

- Medical Equipment – Used in devices such as dental drills, centrifuges, and imaging systems for their quiet and stable operation.

- Aerospace and Defense – Provides reliability and performance in lightweight, high-speed environments.

- Machine Tools – Ensures accuracy and stability in spindle systems and cutting machinery.

- Electric Motors – Enhances performance in micro-motors and precision drives.

- Optical Instruments – Delivers smooth and controlled movement in microscopes and measuring equipment.

- Textile and Printing Machines – Supports high-speed rotation and long operational cycles.

Single Row vs Double Row Miniature Angular Contact Bearings

Single Row Bearings

Single row angular contact bearings are designed to handle axial loads in one direction. They are commonly used in paired configurations where one bearing handles thrust loads in one direction while another takes the load in the opposite direction.

Double Row Bearings

Double row angular contact bearings combine the function of two single row bearings in a compact form. They can handle axial loads in both directions and are ideal for applications where space and alignment precision are crucial.

Why Choose SDTFL Miniature Angular Contact Ball Bearings

1. Superior Precision

SDTFL manufactures each bearing with strict precision standards to ensure flawless operation in high-speed and high-accuracy applications.

2. High-Quality Materials

Using advanced heat-treated bearing steel and corrosion-resistant coatings, our bearings deliver durability even in demanding environments.

3. Advanced Manufacturing Technology

Our production facilities utilize automated machining and quality testing systems to maintain consistent tolerances and performance.

4. Customization Options

We offer a wide range of sizes, contact angles, lubrication types, and materials to meet specific customer requirements.

5. Proven Reliability

SDTFL miniature bearings are trusted by clients across automotive, aerospace, and industrial sectors for their stability and performance.

Maintenance and Handling Tips

To ensure optimal performance and long service life, proper maintenance and handling are essential:

- Keep bearings free from contaminants such as dust and moisture.

- Avoid applying excessive force during installation to prevent internal damage.

- Use suitable lubricants recommended for specific temperature and load conditions.

- Regularly inspect for wear or unusual noise to detect potential issues early.

Future of Miniature Bearing Technology

As technology continues to evolve, the demand for smaller, more efficient mechanical components is growing rapidly. Future advancements in materials, coatings, and manufacturing precision will further enhance the speed, efficiency, and load-bearing capacity of miniature angular contact ball bearings.

SDTFL Bearing remains committed to innovation, continuously improving our designs to meet the evolving demands of industries worldwide.

Conclusion: Compact Power and Precision Engineering

Miniature angular contact ball bearings are a vital component in the world of high-precision machinery. Combining compact size with superior performance, they offer unmatched efficiency, load capacity, and longevity. At SDTFL Bearing, our miniature angular contact bearings are engineered with precision, using the finest materials and advanced manufacturing technologies to ensure consistent, reliable performance across applications.

Whether you require a standard solution for robotics or a custom design for aerospace applications, we are ready to assist you in finding the perfect fit for your specific needs. Do not let friction slow down your progress; let us help you achieve the stability and speed your machinery deserves.

Take the Next Step for Precision Performance

Ready to optimize your machinery with superior components? Contact us today to request a customized quote or consult with our technical team regarding your specific requirements.

- Email Us: info@sdtflbearing.com

- Call Us: +86 15806631151

Alternatively, click the inquiry button on the sidebar to send us a direct message. We look forward to powering your success.