Selecting the right flanged ball bearing demands careful attention to your application’s load, speed, and environment. When you choose a bearing that matches your needs, you extend equipment life and improve reliability. Review the table below to see how critical parameters influence bearing performance:

| Parameter | Description | Numerical Values / Formula |

|---|---|---|

| Minimum Bearing Load (Pmin) | Minimum load to avoid skidding | Pmin = 0.02 × C (Dynamic Capacity) |

| Bearing Dynamic Capacity (C) | Radial load for 1 million revolutions | Varies by bearing; max operating load ≈ 0.5 × C |

| Bearing Static Capacity (Co) | Max load on non-rotating bearing without damage | 4600 MPa (self-aligning ball), 4200 MPa (other ball), 4000 MPa (roller) |

| L10 Rating Life Calculation | Basic rating life for 90% reliability | Lna = a1 × a2 × a3 × L10 |

You gain better results when you use a bearing selection guide and consider factors like material, cage design, and mounting features. Each flanged ball bearing offers specific properties for fatigue strength, corrosion resistance, and speed. The chart below shows how reliability factors affect bearing life:

Remember, you achieve optimal performance when you choose a bearing that fits your unique requirements.

Key Takeaways

- Choose a flanged ball bearing that matches your load, speed, and environment to ensure long equipment life and reliable performance.

- Measure your shaft, housing, and flange carefully to get the right size and fit, preventing misalignment and early failure.

- Select bearing materials and seals based on your environment; stainless steel and sealed bearings work best in wet or harsh conditions.

- Follow a step-by-step selection process, including load and speed assessment, fit checks, and consulting manufacturer data to avoid costly mistakes.

- Buy from trusted suppliers who offer quality products, warranties, and technical support to get the best value and expert help when needed.

Application Needs

Load & Capacity

You need to understand the type of load your flange bearing will handle. Loads can be radial, axial, or a combination of both. Radial loads push perpendicular to the shaft, while axial loads push along the shaft. Many ideal applications require bearings to support both types. Use the table below to help you calculate the right load for your flange bearing:

| Measurement Statistic | Description | Formula / Notes |

|---|---|---|

| Equivalent Dynamic Bearing Load (P) | Combines radial and axial loads | P = X · Fr + Y · Fa |

| Basic Static Load Rating (Cor) | Max static load without damage | Varies by material |

| Bearing Safety Factor (fs) | Ensures safety under unexpected loads | fs = Cor / P |

| Basic Dynamic Load Rating (Cr) | Load for 1 million revolutions | Used for life calculation |

| Basic Rating Life (L10) | Expected life under load | L10 = (Cr / P)^3 × 10^6 rev |

When you know your load, you can select a flange bearing that meets your needs and ensures long service life in ideal applications.

Speed

Check the speed your application requires. Flange bearings have speed limits based on their design and type. Ball bearings can reach up to 30,000 RPM, making them suitable for electric motors and other high-speed ideal applications. Roller bearings handle heavier loads but run at lower speeds. Use the table below to compare:

| Bearing Type | Max Speed Limit (RPM) | Typical Applications |

|---|---|---|

| Ball Bearing | Up to 30,000 | Electric motors, fans |

| Roller Bearing | Up to 12,000 | Conveyors, trucks |

If your ideal applications run at high speeds, choose a flange bearing designed for those conditions. Always check the manufacturer’s speed rating.

Environment

Consider the environment where you will use the flange bearing. High temperatures, moisture, and dust can shorten bearing life. Mining and outdoor ideal applications often expose bearings to these harsh conditions. Seals and shields protect the bearing from dirt and water, helping it last longer. If your flange will face extreme temperatures or lots of dust, pick a bearing with strong seals and corrosion-resistant materials.

Tip: Always check if your flange bearing has the right protection for your environment. This step prevents early failure in demanding ideal applications.

Size & Fit

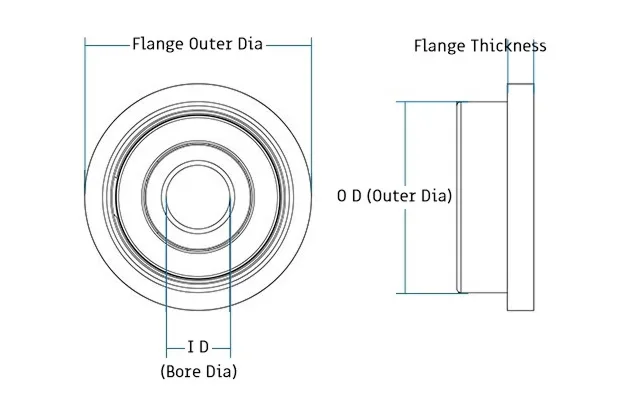

Measure your shaft and housing carefully. The flange must fit the mounting surface and align with the shaft. Use calipers to check shaft diameter and housing bore. Make sure the flange matches the bolt pattern and mounting holes. A proper fit keeps the bearing stable and prevents misalignment in ideal applications.

- Measure shaft diameter and length.

- Check housing bore size.

- Match flange dimensions to your mounting surface.

- Confirm bolt hole size and spacing.

Choosing the right size and fit ensures your flange bearing works smoothly and lasts longer in all ideal applications.

Flanged Ball Bearing Types

Materials

You will find that the material of your flange bearing plays a key role in its performance and durability. Most flange bearings use steel or stainless steel. Steel flange bearings offer high strength and can handle heavy loads. Stainless steel flange bearings provide superior corrosion resistance, making them ideal for wet or harsh environments. Industry research uses both primary and secondary data, including expert interviews and technical reports, to confirm that stainless steel deep groove ball bearings deliver high load capacity and long service life. Advanced alloys and precision tolerances, such as ABEC-5 and ABEC-7, help these bearings perform well in demanding applications like medical equipment. When you select the right material, you ensure your bearing remains durable and reliable.

- Steel flange bearing: Best for heavy loads and general use.

- Stainless steel flange bearing: Best for moisture, chemicals, or outdoor use.

Tip: Always match the bearing material to your environment for the most durable results.

Seals & Lubrication

Seals and lubrication protect your bearing from damage and keep it running smoothly. You can choose open, sealed, or shielded bearings. Sealed bearings keep out dust and water, while shielded bearings offer moderate protection. Proper lubrication reduces friction, carries away heat, and prevents rust. Studies show that vibration and temperature monitoring can measure how well lubrication works. If you use the right lubricant and seal, your flange bearing will last longer and need less maintenance.

| Seal Type | Protection Level | Maintenance Needs |

|---|---|---|

| Open | Low | High |

| Shielded | Medium | Medium |

| Sealed | High | Low |

Regular checks on lubrication and seals help you avoid early bearing failure.

Flange Designs

You will see different types of bearings with various flange shapes and sizes. The flange supports the bearing and helps with mounting. Design studies compare flange shapes like unstiffened, stiffened, and those with return lips. These studies use both experiments and computer models to test how each flange handles pressure and vibration. Results show that certain flange designs, such as those with stiffening lips, provide better support and safety in tough conditions. Guides also explain that you should match the flange design to your application’s needs, such as pressure, temperature, and ease of maintenance. By choosing the right flange, you make your bearing more durable and reliable in any environment.

Selection Process

Right Bearing for Your Application

You want to find the right bearing for your application. Start by reviewing your requirements. Each step helps you match the bearing to your needs and avoid costly mistakes. Use this step-by-step approach:

- Define your application’s load, speed, and environment.

- Select the correct fit for your flange. Interference fits work best for high-load, high-speed uses. Transition fits suit moderate loads and allow easier assembly. Clearance fits help in low-load or low-speed situations or when you expect thermal expansion.

- Choose a bearing type that matches your load and speed. Roller bearings handle heavy radial loads. Tapered roller bearings work for combined loads. Thrust bearings support high axial loads. Rod end bearings help with angular misalignment.

- Reference real-world examples from industries like automotive, aerospace, and machinery. These benchmarks help you see which bearing types succeed in similar ideal applications.

- Follow best practices for mounting and installation. Keep the area clean. Check fit and tolerances. Use the right tools to prevent damage.

- Consider lubrication needs. High-speed ideal applications need more attention to lubrication for heat control and long life.

- Review technical specifications from the manufacturer. Check load capacity, speed rating, and dimensions before you choose a bearing.

A bearing selection guide can help you compare options and make the best choice for your flange bearing.

Load & Speed Assessment

You must assess load and speed to ensure the right bearing for your application. Use both physical and data-driven methods to predict how your bearing will perform.

- Statistical models help you estimate bearing life and spot early signs of wear.

- Machine learning tools use operational data to improve reliability predictions.

- Hybrid approaches combine physical tests with data analysis for better accuracy.

For example, engineers use frictional-energy damage metrics to detect early cracks in bearings. They also map loads from rotors to gearboxes and calculate how much damage may occur over time. These methods help you predict failure and choose a bearing that will last in your ideal applications.

Tip: Always use both technical data and real-world measurements to confirm your bearing can handle the expected load and speed.

Environment & Fit Check

You need to check if your bearing matches the environment and fits your flange. Environmental compatibility ensures your bearing will not fail early due to dust, moisture, or temperature swings. Use statistical performance indicators to verify your choice.

| Indicator Type | Description | Application Notes |

|---|---|---|

| Data Distributions | Show how environmental data behaves (normal, lognormal, gamma, nonparametric). | Help you pick the right analysis method for your data. |

| Goodness-of-Fit Tests | Check if your data matches expected patterns (Shapiro-Wilk, Kolmogorov-Smirnov, Anderson-Darling). | Confirm your data is reliable for analysis. |

| Outlier Detection Tests | Find unusual data points (Dixon’s, Discordance, Rosner’s, Walsh’s). | Remove outliers to improve your compatibility check. |

| Statistical Software | Tools like USEPA ProUCL help with tests and trend analysis. | Make your environmental data review more complete. |

Measure your shaft and housing with care. Double-check the flange dimensions and bolt pattern. A good fit prevents misalignment and keeps your flange bearing stable in all ideal applications.

Compatibility

You must confirm that your bearing is compatible with your system. Review the following:

- Check that the bearing’s size, load, and speed ratings match your application.

- Make sure the flange design fits your mounting surface and bolt pattern.

- Confirm that seals and lubrication meet your environment’s needs.

- Use manufacturer data to compare technical specs.

Note: Many users make mistakes by measuring only once or ignoring small differences in size. Always measure twice and check all dimensions before you choose a bearing.

Common Measurement Mistakes and How to Avoid Them

- Measuring only the shaft or only the housing. Always measure both.

- Ignoring thermal expansion. Allow for changes in size due to temperature.

- Overlooking the bolt hole spacing on the flange. Double-check all mounting points.

- Using worn or inaccurate tools. Calibrate your calipers and measuring devices.

If you follow these steps, you will find the right bearing for your application and avoid common pitfalls. The right process ensures your flanged ball bearing delivers reliable performance in all ideal applications.

Mistakes to Avoid

Ignoring Load Ratings

You must always check the load ratings before you select a bearing. Many users skip this step and face early equipment failure. Inadequate bearing selection, often from ignoring load ratings, causes about 10% of premature bearing failures. Overloading a bearing leads to plastic deformation at contact points, which speeds up failure. If you double the typical load, you can reduce the bearing’s life by up to 90%. Overloading may also result from excessive preloading or incorrect mounting. Always match the bearing’s load rating to your application to avoid these costly mistakes.

Tip: Never guess the load your bearing will face. Use manufacturer data and real measurements to confirm the right choice.

Overlooking Environment

You need to consider the environment where your bearing will operate. Many failures happen because users ignore temperature, moisture, or contamination. If you use a bearing in a harsh environment without proper seals or lubrication, you risk problems like frosting, debris denting, or surface spalling. These issues come from poor lubrication, contamination, or incorrect fitment. Vibration and excess clearance can also cause fretting, which damages the bearing over time.

- Common causes of bearing failure in tough environments:

- Insufficient lubrication or fine contamination

- Hard particles causing debris denting

- Metal fatigue from worn surfaces

- Vibration and excess clearance

You can prevent these problems by choosing the right seal, using proper lubrication, and controlling contamination.

Skipping Guidelines

You should always follow industry guidelines when you install or handle a bearing. Many users make mistakes with fits, which can affect bearing clearance, speed, and temperature. Incorrect fits, such as interference or loose fits, can distort raceways or cause unwanted movement. The best practice is to use a line-to-line fit with no interference or looseness. This requires accurate measurement and machining.

- Common measurement mistakes and their impact:

- Choosing the wrong fit for load, speed, or temperature

- Using inaccurate tools or measuring only one part

- Ignoring bolt hole spacing or thermal expansion

Note: Always measure both the shaft and housing. Double-check all dimensions before you mount the bearing.

By avoiding these mistakes, you help your bearing last longer and perform better in any application.

Where to Buy

Trusted Suppliers

When you choose a flanged ball bearing, always start with a trusted supplier. Reliable vendors help you avoid counterfeit products and ensure you get the right quality. Look for suppliers with a strong reputation, clear quality metrics, and a history of serving your industry. You can use the table below to compare important supplier features:

| Supplier/Brand | Reputation & Market Presence | Quality Metrics & Features | Notable Strengths |

|---|---|---|---|

| TFL | Globally recognized, decades refining processes | Strict quality control, advanced heat treatment, adherence to load ratings and tolerances | Reliable cast housings, premium quality |

Key quality metrics include shaft size compatibility, load ratings, speed limits, and environmental resistance. Always buy from authorized distributors to avoid fake bearings. You can also check customer reviews and performance ratings to see how each supplier supports your needs.

Warranty & Support

A good supplier offers clear warranty terms and strong support. Before you buy, review the return policy and warranty period. Some suppliers give you a 30-day return window, while others offer up to 60 days. You should also check if the supplier reimburses shipping costs if the product does not match your order. Fast and helpful customer service makes a big difference if you have questions or need to return a bearing.

Tip: Always keep your purchase records and warranty information. This helps you get support quickly if you need it.

Technical Help

You may need technical help when choosing or installing a bearing. Trusted suppliers provide resources like 24/7 hotlines, live chat, or email support. Some even offer technical guides or online tools to help you select the right bearing for your application. If you have a unique setup or need expert advice, reach out to the supplier’s technical team.

- Check if the supplier offers:

- Technical documentation

- Installation guides

- Live support or quick email responses

If you want expert advice or need help choosing the best bearing, contact TFL’s support team. You can get personalized recommendations and ensure your product fits your needs.

You can choose the right flanged ball bearing by following a clear process. First, review your load, speed, and environment. Next, match each bearing feature to your application needs. Always measure carefully and check fit. For complex setups, ask an expert or supplier for help. You want the best product for your equipment. Contact TFL for support or to explore the full bearing selection.

FAQ

What is the main advantage of using a flanged ball bearing?

You get easier mounting and better alignment. The flange keeps the bearing in place and stops it from moving. This design works well in applications where you need extra support or precise positioning.

How do you measure for the correct flanged ball bearing size?

Use a caliper to measure the shaft diameter and the housing bore. Check the flange diameter and bolt hole spacing. Always measure twice to avoid mistakes. Accurate measurements help you choose the right bearing.

Can you use flanged ball bearings in wet or dirty environments?

Yes, you can. Choose stainless steel bearings with strong seals. These features protect against moisture and dirt. Proper lubrication also helps prevent rust and wear.

How often should you lubricate a flanged ball bearing?

Check the manufacturer’s guidelines. For most applications, inspect and lubricate every few months. If you use the bearing in harsh conditions, increase the frequency. Regular lubrication extends bearing life.

What should you do if your bearing makes unusual noise?

Stop the machine and inspect the bearing. Noise often means damage, lack of lubrication, or contamination. Replace the bearing if you see wear or damage. Clean and lubricate before restarting.