Bearings use seals made from many polymer materials. The most common ones are Nitrile Rubber (NBR), Fluorocarbon Rubber (FKM), Hydrogenated Nitrile Rubber (HNBR), Silicone Rubber (VMQ), PTFE, Polyurethane, ACM, EPDM, PA66-GF, and metal-reinforced types. The table below shows the market share and features of the top five polymer bearing materials used in bearing seals:

| Polymer Material | Market Share / Usage Percentage | Key Attributes / Usage Context |

|---|---|---|

| Nitrile Rubber (NBR) | Over 30% market share | Low cost, useful for many things, used in engines and light jobs |

| Polyurethane (PU) | Growing use, CAGR 5.9% through 2032 | Strong and resists wearing out |

| Fluorocarbon Rubber (FKM) | Over 18% material segment value share | Handles high heat and tough fluids |

| Silicone | Not specified | Used for special jobs |

| PTFE | Growing at CAGR 7.1% by 2033 | Used for special jobs, slides easily, lasts long |

Picking the right seal material for polymer bearings is important. It helps bearings keep out dirt and water. It also keeps oil inside and works well in hard places. Good bearing seals lower friction, stop oil from leaking, and keep bearings safe. The right polymer seals help bearings last longer and work better in all uses.

Key Takeaways

- Bearing seals keep dirt and water out of bearings. They also keep oil or grease inside. This helps bearings last longer and work better.

- Some common seal materials are Nitrile Rubber (NBR), Polyurethane, Fluorocarbon Rubber (FKM), Silicone, and PTFE. Each one has special strengths like handling heat or chemicals.

- Picking the right seal material depends on the job’s temperature. It also depends on chemical exposure and how much wear will happen. This makes sure the seal works well and lasts a long time.

- New advanced polymers and better seal designs help seals fight wear and chemicals. They also help seals work in tough places. This makes bearings more reliable.

- Always choose the seal material that fits the job and lubricant type. This gives the best protection, lowers friction, and helps bearings last longer.

Functions of Bearing Seals

Contaminant Protection

Seals are very important for keeping bearings clean. They stop many things that can hurt the bearing. Some common problems are:

- Dust and dirt from outside

- Water or wet air

- Chemicals from cleaners or other liquids

- Tiny metal pieces from making or using the bearing

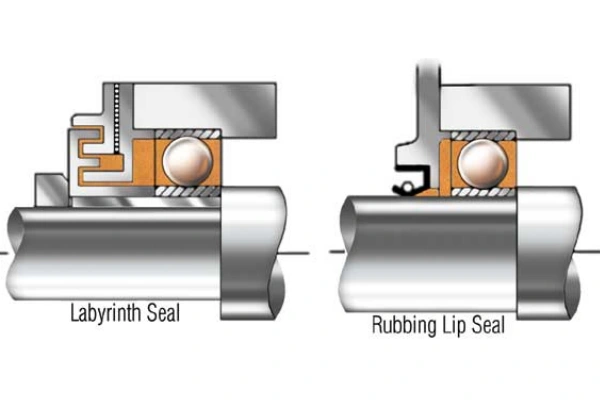

Seals fit tightly around the bearing to block these things. Some seals do not touch the shaft. These are called labyrinth seals. They make a twisty path that stops dust and water. Other seals have a rubber lip that rubs on the shaft. This keeps out bad stuff. These seal types help bearings work well and last longer.

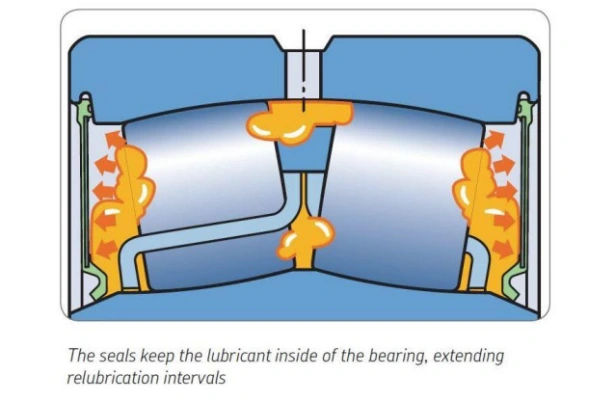

Lubricant Retention

Seals also keep oil or grease inside the bearing. Oil and grease help parts move smoothly and stop them from wearing out. If seals are not good, oil or grease can leak out. Then the bearing can dry out and break. Different seals hold oil or grease in different ways. The table below shows how each seal works:

| Seal Type | Lubricant Retention Mechanism | Suitability |

|---|---|---|

| Metal Seals | Tight contact barrier | Automotive, machinery |

| Rubber Seals | Lip seal with direct shaft contact | Versatile, many environments |

| Felt Seals | Wicking action holds lubricant | Low-speed, cost-effective |

| Labyrinth Seals | Non-contact, tortuous path | High-speed, harsh environments |

| Teflon Seals | Low friction, chemical resistance | Extreme conditions |

Seals stop oil or grease from leaking out. They help bearings last longer, even when things get tough.

Environmental Resistance

Seals protect bearings from tough places. They close the space between the housing and the shaft. This keeps out dust, water, and chemicals. In dirty or wet places, more than one seal or sealed-for-life bearings give extra safety. Some seals have special coatings or materials to fight chemicals and rust. Others use spring lips or felt wipes to block dirt. Automatic oilers can add grease to keep out dust and water. Changing seals often keeps the protection strong. These things help bearings work in factories, outside, and other hard places.

Common Seal Materials in Bearings

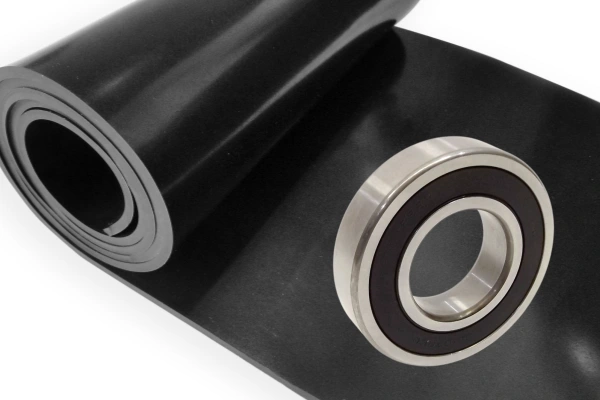

Nitrile Rubber (NBR)

Nitrile Rubber (NBR) is one of the main seal materials. It works in temperatures from -40°C to 100°C. Some special types can go up to 120°C for a short time. This polymer does not break down in oil, fuel, grease, or water under 100°C. NBR is tough and does not tear easily. It is a good choice for most bearing seals. In cold places, NBR stays soft and bends well. This helps it keep a good seal. Most bearings use NBR because it is cheap, strong, and works well with oil.

Tip: NBR seals are best when you need oil resistance and flexibility in the cold.

Property | NBR Description / Range |

|---|---|

| Temperature Resistance | -40°C to 100°C (short-term up to 120°C) |

| Chemical Compatibility | Good with petroleum oils, greases, water; not suitable for strong acids or solvents |

| Wear Properties | Good abrasion and tear resistance; maintains flexibility in cold |

| Typical Applications | General-purpose bearings, automotive, light machinery |

Hydrogenated Nitrile Rubber (HNBR)

Hydrogenated Nitrile Rubber (HNBR) is better than regular NBR. It can handle more heat and more chemicals. HNBR seals work from -40°C to 150°C. They can go up to 170°C for a short time. This material does not get damaged by heat, oil, sour gas, ozone, or steam. HNBR is stronger and lasts longer than NBR. It is used in cars, oil and gas, and big machines.

- HNBR seals can handle acids, bases, salts, and oils.

- They do not wear out fast, even in hot oil.

- HNBR should not be used with ketones, esters, ethers, or strong acids.

| Performance Aspect | HNBR Characteristics |

|---|---|

| Thermal Resistance | -40°C to 150°C (short-term up to 170°C) |

| Chemical Resistance | Excellent with oils, fuels, refrigerants, acids, bases, and ozone |

| Wear Properties | Superior abrasion and mechanical strength |

| Typical Applications | Wheel bearing seals, dust covers, automotive, oil and gas, industrial machinery |

Fluororubber (FKM/Viton)

Fluororubber (FKM/Viton) is also a top seal material. FKM seals work from -20°C to 200°C. Some types can go up to 225°C. This polymer does not get damaged by many chemicals. It can handle acids, alkalis, oils, and solvents. FKM keeps its shape and seals well in high heat and pressure. It is used in planes, chemical plants, and oil and gas.

- FKM seals can take high heat and strong chemicals.

- They do not change shape or get old fast.

- These seals stop gas from leaking and work well in hard places.

Note: FKM is best when you need both high heat and chemical resistance.

Silicone Rubber (VMQ)

Silicone Rubber (VMQ) is very flexible and seals well in hot and cold. VMQ seals stay soft down to -70°C. They can take heat up to 200°C, or 250°C for a short time. This polymer is not good for high pressure but is great for big temperature changes. VMQ does not get damaged by ozone, weather, or age. It is used outside, in medical tools, and in food machines. Silicone is not as strong as FKM or polyurethane, but it works well when temperature is the main problem.

- VMQ seals are used in planes, electronics, and home appliances.

- They stay flexible and seal well when other materials might fail.

Polyurethane

Polyurethane seals are very tough and can hold heavy loads. They are used in moving parts of bearings. Polyurethane works from -40°C to 100°C. It does not get damaged by oil, grease, water, or hydrocarbons. This polymer can also take some acids and alkalis. Polyurethane lasts much longer than NBR in rough places. Wind power, mining, and big machines use these seals because they are strong and resist chemicals.

- Polyurethane seals do not swell or break down in wet or oily places.

- They also resist ozone and sunlight, especially with special additives.

Polyamide (PA66-GF)

Polyamide 66 with glass fiber (PA66-GF) is used as a strong base in some seals. PA66-GF is stiff and can take heat up to 310°C. The glass fiber makes it even stronger and keeps its shape. This is important for keeping the seal working right. PA66-GF does not wear out fast and resists chemicals. It is often used with a soft sealing lip like NBR or FKM. This makes a seal that is both hard and flexible.

Note: Seals with PA66-GF are common in high-performance bearings.

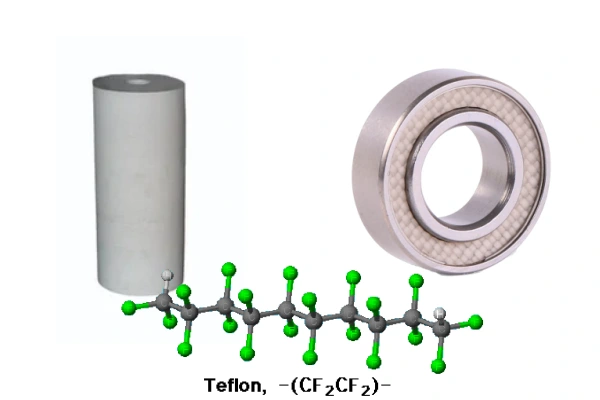

PTFE (Teflon)

PTFE (Teflon) can handle very hot and very cold places. PTFE seals work from -260°C to 260°C. This polymer does not react with almost any chemical. It is very slippery, so it does not wear out fast. PTFE keeps its shape when temperatures change. It is self-lubricating and does not let water stick to it. Some types have glass or carbon added to make them even stronger. PTFE seals are used in food, medicine, and chemical plants where safety and long life are needed.

| Property | PTFE Description |

|---|---|

| Temperature Resistance | -260°C to 260°C |

| Chemical Resistance | Near-universal; resists acids, bases, solvents, and aggressive fluids |

| Wear Properties | Low friction, self-lubricating, excellent wear resistance |

| Typical Applications | Food processing, pharmaceuticals, chemical plants, high-speed and dynamic bearing seals |

ACM and EPDM

ACM and EPDM are special seal materials for certain jobs. ACM can take more heat, oil, and chemicals than NBR. It works from -20°C to 130°C. ACM is used in power steering, gearboxes, and engines. EPDM is good with solvents, hot water, and steam. It works from -50°C to 150°C. EPDM is not good with oil but is used in brakes and steam systems.

| Material | Temperature Range (°C) | Oil Resistance | Chemical Resistance | Applications |

|---|---|---|---|---|

| ACM | -20 to 130 | Good with mineral oils, engines, gearboxes | Good chemical resistance | Power steering, transmissions |

| EPDM | -50 to 150 | Not resistant to mineral oils or hydrocarbons | Excellent with solvents, hot water, steam | Brake systems, steam seals |

Metal-Reinforced Seals

Metal-reinforced seals have a metal center and a polymer lip. The metal makes the seal strong and keeps its shape. The polymer lip is soft and seals well. These seals are used where there is high pressure, heat, or heavy loads. Metal-reinforced seals are found in big bearings, cars, and machines. The mix of metal and polymer helps the seal last longer and work better.

Tip: If you need a seal for heavy loads or a perfect fit, metal-reinforced seals are a good choice.

Material Properties Comparison

Temperature Resistance

Temperature resistance is very important for seals. Some materials can take more heat or cold than others. PTFE seals work from -80°C to 200°C. This means they are good for freezing and hot places. Silicone seals also work in many temperatures, from -54°C to 204°C. NBR seals do best between -30°C and 100°C. Polyurethane seals work from -54°C to 93°C. FKM seals can take heat up to 180°C. This helps in very hot jobs. EPDM seals stay soft in cold and can take heat up to 150°C.

If temperatures change fast, silicone and PTFE seals work best.

Chemical Resistance

Chemical resistance keeps seals safe from oils and chemicals. NBR seals block damage from oils and fuels. This is why cars use them a lot. PTFE seals work with most chemicals, like acids and bases. FKM seals are great with alcohol and special fuels. EPDM seals work with steam, water, and some acids. They do not work with oil. Polyurethane seals block damage from hydraulic fluids and air. HNBR seals are better with new fuels and heat.

| Material | Chemical Resistance / Fluid Compatibility |

|---|---|

| NBR | Good with petroleum oils, diesel, gasoline |

| PTFE | Compatible with most chemicals, acids, bases, solvents |

| EPDM | Good for steam, acetone, dilute acids and bases; not for petroleum fluids |

| Polyurethane | Resistant to hydraulic fluids, abrasion, oxidation |

| Silicone | Suitable for pharmaceutical and food contact |

| FKM | Excellent with alcohol, aromatic fuels |

| HNBR | Excellent with modern fuels, heat, abrasion |

Wear and Durability

Wear and durability show how long seals last. Polyurethane seals are strong and take heavy loads. PTFE seals are slippery and do not wear out fast. NBR seals are good for stopping wear in normal jobs. FKM seals keep their shape and do not get old in heat. HNBR seals last longer than NBR in hot oil and rough places. EPDM and silicone seals do not get hurt by weather or sun. This helps them last outside.

- Polyurethane and PTFE seals are best for places with lots of wear.

- FKM and HNBR seals last a long time in hot or tough places.

Cost Factors

Cost matters when picking seals for a job. NBR seals are cheap and work for most things. Polyurethane seals cost more but last longer in hard jobs. PTFE and FKM seals cost the most because they fight heat and chemicals. Silicone and EPDM seals cost in the middle. They are good for special needs. Pick a seal by thinking about cost, heat, and chemicals.

| Feature | PTFE Oil Seals | NBR Oil Seals |

|---|---|---|

| Cost | Higher | More affordable |

| Best Use | High-temp, chemicals | General-purpose |

Always pick a seal that matches the job and the oil used. This gives the best value and makes the seal work well.

Innovations in Bearing Seals

Advanced Polymers

Engineers are making new materials for bearing seals. These new materials help seals last longer and work better in hard jobs. The table below lists some new high-performance polymers and what they do:

| Advanced Polymers Introduced | Associated Seal Products and Applications | Performance Improvements and Benefits |

|---|---|---|

| Hytrel© | Polymer seals, injection molded parts | Better wear resistance, flexibility, and durability |

| Kynar – PVDF | Polymer seals, encapsulated products | Resists chemicals, strong and tough |

| Nylon Polyamide 66 | Polymer bushings/bearings, piston rings | Strong and resists wearing out |

| PEEK | High-performance seals, bushings | Handles high heat, resists chemicals |

| PTFE | Spring energized seals, rotary shaft seals, extruded rods, sheets, tubes | Slides easily, resists chemicals, lasts in tough places |

| PPS | Machined parts, injection molded seals | Stays stable in heat, resists chemicals |

| Torlon | Machined parts, high-performance seals | Very strong, resists wearing out |

| UHMW PE | Wear sleeves, bushings | Great at stopping wear, takes hard hits |

These new polymers help seals fight wear and chemicals. They also make seals stronger and able to work in very tough places. Many industries use these materials to make seals last longer and work better. Oil and gas, planes, and cars all use these new seal materials.

New Seal Designs

Seal makers have made new designs to fix common problems. These new designs help seals keep out dirt and hold in grease better.

- NSK made a seal that is strong and does not cause much friction. This helps the seal protect the bearing without slowing it down.

- SKF made a three-barrier seal system. It has an outside seal, a space with grease, and an inside seal. This keeps out dirt and keeps grease inside.

- These new designs help seals last longer and protect bearings in hard places.

Tip: Using new seal designs and new materials together gives bearings better protection and helps them last longer.

Picking the right seals for bearings is important. Seals keep dirt out and oil inside the bearing. Rubber seals stop dust and water from getting in. This helps the bearing last longer and need less fixing. Metal seals block dust but are best when it is dry. The table below shows how each seal works in tough places:

| Material | Max Temperature | Chemical Resistance | Best Use |

|---|---|---|---|

| Silicone | 230°C | UV, ozone, oxygen | Aerospace, automotive |

| PTFE | 260°C | Most chemicals | Pharmaceuticals, plumbing |

| FKM | 225°C | Oils, fuels | Industrial, automotive |

Seals stop inside parts from wearing out or rusting. Experts say to read the technical data before picking a seal. It is smart to ask a specialist if the job is hard. Some seals, like PTFE or FKM, give more safety in tough jobs. Always use the right seal for the job to get the best results.

FAQ

What are the main functions of bearing seals in bearings?

Bearing seals stop dirt and water from getting in. They keep oil and grease inside the bearing. This helps the bearing last longer and work better. Good seals also stop damage and wear.

Which materials offer excellent wear resistance for bearing seals?

Polyurethane, PTFE, and bearing grade peek are very tough. These materials help seals last longer in hard jobs. High-performance polymers like torlon and pps make bearings even stronger.

Why do engineers choose high-performance polymers for bearing seals?

Engineers use high-performance polymers because they fight heat and chemicals. These materials work well in rough places. They help seals keep their shape and stop leaks in bearings.

How do lubricants interact with different seal materials?

Lubricants need to fit the seal material. Some polymers, like NBR and PTFE, work with many oils. The right match keeps seals strong and helps bearings work well.

What are the top five polymer bearing materials used in seals?

The top five polymer bearing materials are NBR, polyurethane, FKM, silicone, and PTFE. These materials protect bearings, stop wear, and help seals last a long time.