Selecting the correct bearing is critical for machine reliability, performance, and service life. However, one of the biggest challenges engineers and buyers face is understanding bearing identification codes. At first glance, bearing codes may appear complex, consisting of numbers and letters with no obvious meaning. In reality, these codes follow standardized rules that clearly describe the bearing’s size, type, design, and special features.

This bearing code guide explains how to read bearing codes and practically. By understanding these codes, engineers can ensure proper technical selection, while procurement teams can avoid costly ordering mistakes and compatibility issues.

Table: Typical Bearing Code Components and Their Meaning

| Code Element | What It Indicates |

| Bearing type number | Basic bearing design |

| Series number | Load capacity and cross-section |

| Bore code | Shaft diameter |

| Prefix | Special design or application |

| Suffix | Internal design, clearance, sealing |

What Is a Bearing Code

A bearing code is a standardized identification system used by bearing manufacturers to describe a bearing’s characteristics. The code typically includes information about the bearing type, series, bore size, internal design, cage type, sealing, and special features.

While different manufacturers may use slightly different formats, most bearing codes follow international standards such as ISO and DIN. Learning how to interpret these codes allows users to quickly identify whether a bearing is suitable for a specific application without relying solely on catalogs or datasheets.

SDTFL Factory Insight: Confused by a specific manufacturer’s code? As a direct factory, we can cross-reference any global brand code to our equivalent high-precision series. Contact SDTFL for a Cross-Reference Check.

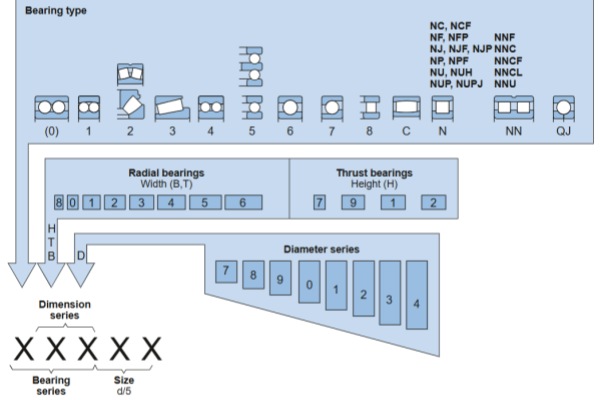

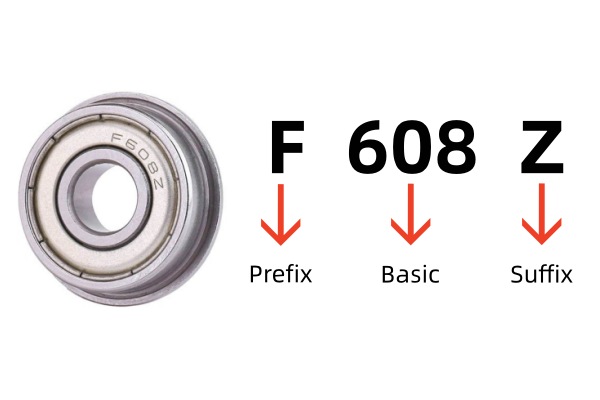

Basic Structure of a Bearing Code

Most bearing codes consist of three main parts: a basic designation, optional prefixes, and optional suffixes. The basic designation usually includes the bearing type, size series, and bore diameter. Prefixes and suffixes provide additional information about design variations, materials, or special performance features.

Understanding this structure is the foundation of any effective bearing code guide. Once the logic is clear, even long bearing codes become easy to interpret.

Need a Custom Designation? We don’t just read codes; we create them. SDTFL offers OEM manufacturing services where we can mark bearings with your specific branding and coding requirements. Discuss OEM Solutions with Us.

Bearing Type Identification

The first part of a bearing code often indicates the bearing type. This section tells you whether the bearing is a deep groove ball bearing, angular contact bearing, roller bearing, or another design.

For example, single-digit or double-digit numbers at the beginning of the code are commonly used to represent ball bearings, while different number patterns indicate cylindrical, tapered, or spherical roller bearings. This information helps engineers quickly determine whether the bearing is suitable for radial loads, axial loads, or combined loading conditions.

Browse by Type: Now that you know the type codes, explore our extensive manufacturing catalog:

- Deep Groove Ball Bearings (6000 Series)

- Spherical Roller Bearings (22000 Series)

- Tapered Roller Bearings (30000 Series)

- Angular Contact Ball Bearings (7000 Series)

Understanding the Bearing Series

The bearing series provides information about the bearing’s robustness and load capacity. It reflects the relationship between the outer diameter, width, and bore size. Bearings with a heavier series generally have thicker rings and higher load capacity, while lighter series bearings are more compact.

Series numbers are especially important when space constraints or load requirements are critical. Choosing the correct series ensures the bearing can support operational loads without unnecessary size or weight.

Bore Size Code Explained

One of the most important elements in a bearing code is the bore size designation. For bearings with bore diameters of 20 mm and above, the bore code is typically represented by the last two digits of the basic designation. These digits must be multiplied by five to determine the actual bore size in millimeters.

For example, a bore code of 04 represents a 20 mm bore, while a code of 10 represents a 50 mm bore. Smaller bore sizes usually follow special coding rules, which are defined by bearing standards. Understanding bore size coding helps ensure proper shaft fit and prevents installation problems.

Common Bearing Code Elements Explained

Prefixes in Bearing Codes

Prefixes appear before the basic bearing designation and are used less frequently than suffixes. When present, they usually indicate special bearing designs or application-specific features. Examples include bearings manufactured for matched sets, special accuracy classes, or non-standard dimensions.

While prefixes are not always required for everyday applications, understanding them is important when dealing with high-precision machinery or customized bearing solutions.

Precision Manufacturing: SDTFL’s production lines are equipped to handle P5 and P4 precision classes often indicated by special prefixes. Learn about our Quality Control Standards.

Suffixes and Their Importance

Suffixes are extremely common and provide detailed information about bearing design features. They may indicate internal clearance, cage material, sealing type, lubrication, or heat treatment. For example, a suffix may show that a bearing has increased internal clearance for high-temperature operation or that it includes seals for contamination protection.

Suffixes are particularly important for procurement teams, as ordering a bearing without the correct suffix can result in performance issues or premature failure, even if the basic bearing size is correct.

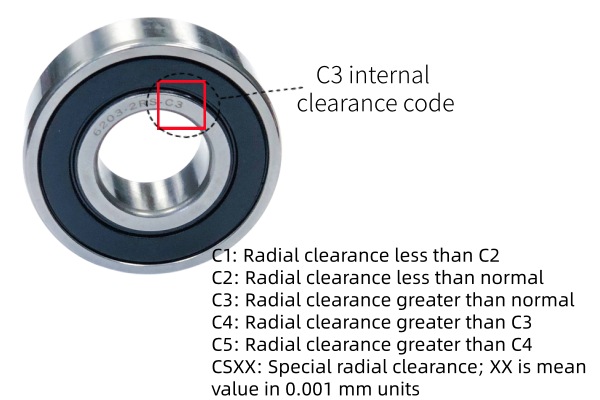

Internal Clearance Codes

Internal clearance refers to the amount of internal play between rolling elements and raceways. Clearance is critical because it affects bearing temperature, noise, and load distribution during operation.

Bearing codes often include suffixes that specify clearance class. Selecting the correct clearance ensures that the bearing performs correctly under operating loads and temperatures. Incorrect clearance selection is a common cause of early bearing failure.

Sealing and Shielding Codes

Bearing codes frequently include suffixes that describe sealing or shielding arrangements. Sealed bearings are designed to prevent contamination and retain lubrication, while shielded bearings offer partial protection with lower friction.

Understanding sealing codes is essential when bearings are used in dusty, wet, or contaminated environments. Proper sealing selection reduces maintenance requirements and extends service life.

Cage and Material Codes

Some bearing codes include suffixes that identify the cage material or special materials used in the bearing. Cage material affects speed capability, temperature resistance, and durability.

Steel cages are commonly used for general applications, while brass or polymer cages may be selected for higher speeds or special operating conditions. In advanced applications, hybrid bearings with ceramic rolling elements may also be identified through specific code suffixes.

Why Bearing Code Knowledge Matters for Buyers

For procurement teams, understanding bearing codes reduces the risk of ordering incorrect components. A single incorrect suffix can result in receiving a bearing that does not meet application requirements, leading to delays and additional costs.

This bearing code guide helps buyers communicate more effectively with suppliers, compare equivalent bearings across brands, and ensure consistent quality across purchases.

Common Mistakes When Reading Bearing Codes

One common mistake is focusing only on bore size and ignoring suffixes. While size compatibility is important, design features such as clearance and sealing are equally critical. Another mistake is assuming that bearing codes are identical across all brands. Although standards exist, some manufacturer-specific variations may apply.

Failing to verify bearing codes against application requirements can result in reduced performance or premature failure. Careful interpretation avoids these issues.

Avoid Costly Returns: Our sales engineers double-check every order against your application data to ensure zero mistakes. Email Us Your Requirements.

Practical Tips for Using Bearing Codes

Always confirm the full bearing code, including prefixes and suffixes, before placing an order. Cross-check bearing codes with technical datasheets when selecting bearings for critical applications. When replacing bearings, ensure the new bearing code matches the original specification unless a design change is intentional.

For complex or high-value equipment, consulting technical experts can help ensure correct bearing selection and long-term reliability.

Understanding how to read bearing codes is an essential skill for engineers, maintenance professionals, and procurement teams. A clear bearing code guide simplifies the selection process, reduces errors, and ensures that the right bearing is chosen for the job.

By learning how bearing type, series, bore size, prefixes, and suffixes work together, users can make informed decisions that improve machine performance, reliability, and service life. Mastering bearing codes ultimately saves time, reduces costs, and supports efficient equipment operation.

Let SDTFL Bearings Decode Your Needs

At SDTFL Bearings, we know that a single digit in a bearing code can make the difference between smooth operation and unexpected downtime. We are not just a supplier; we are a dedicated factory manufacturer committed to precision and reliability. Whether you need help interpreting a complex code, finding a direct replacement for a discontinued part, or manufacturing a custom bearing solution, our engineering team is ready to support you.

Don’t leave your machinery’s performance to chance. Partner with us for factory-direct quality and expert guidance.

- Need a Quick Price Check? Send us your bearing codes at info@sdtflbearing.com

- Require Technical Verification? Call our experts directly at +86 15806631151

- Ready to Order? Click here to browse Our Full Product Catalog and find your exact match.

We ensure you get the right bearing, every time. Contact SDTFL today.