To pick a bearing for machines, you need to follow steps. First, find out the load type—radial, axial, or both. Pick the right bearing type for the load and speed. This could be heavy duty roller bearings or double row tapered roller bearing. Check the roller size, what it is made of, and how to care for it. Use a bearing guide to look at choices. If things are tricky, ask an expert for help. If you want good answers, you can contact TFL Bearings for help.

Key Takeaways

- Find out what kind of load your bearing will hold. Check how strong the load is. Pick a bearing type that fits your machine’s needs.

- Think about how fast the bearing will spin. Use the right oil or grease to stop heat and damage. This helps the bearing last longer.

- Choose bearing materials like stainless steel or ceramic for hard places. These materials stop rust and help the bearing last longer.

- Follow the right steps to put in, fit, and take care of the bearing. This stops the bearing from breaking early. It also keeps machines working well.

- Use a simple checklist to help you choose. Ask experts for help if you need it. This helps you find the best heavy duty roller bearing for your job.

Application Requirements

Load Type

First, you need to know what kind of load is on the bearing. Loads can push in different ways and change which bearing you pick.

- Radial loads push sideways to the shaft. Cylindrical roller bearings or deep groove ball bearings are good for this.

- Axial loads push along the shaft. Thrust bearings or angular contact ball bearings work best here.

- Combined loads push both ways at the same time. Angular contact bearings or tapered roller bearings, like double row tapered roller bearing, can handle these.

- Many machines, like pumps and fans, have combined loads. You must match the bearing type to the way and strength of the load to keep things safe.

Load Capacity

You need to figure out how much load the bearing must hold.

- First, measure the forces on the bearing—radial, axial, or both.

- Think about how often the machine works.

- Check if you need a bearing that can hold heavy loads.

- Use tools or software to help pick the right size.

- Do not pick a bearing that is too big, as it costs more and is heavier.

- Use the L10 life equation to guess how long the bearing will last: L10 = (C / P)^3 × 1,000,000 revolutions.

Dynamic load rating and static load capacity help you choose the right heavy duty roller bearings, double roller bearing, or double row bearing.

Tip: Always make sure the bearing can handle the forces so it does not fail early.

Speed

Speed is important when picking a bearing. High speeds make more friction and heat, which can make the bearing wear out faster. You must check the speed limits for each bearing type.

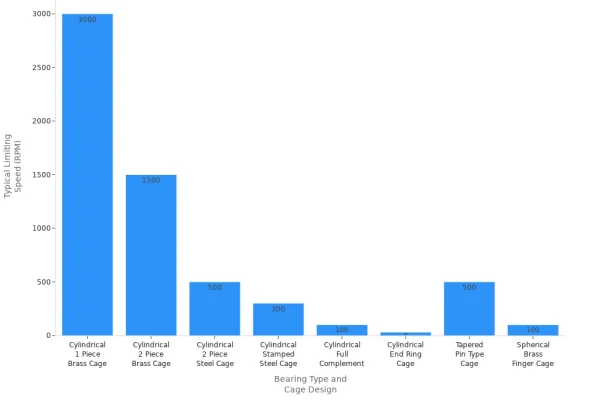

Here is a table that shows normal speed ranges for heavy duty roller bearings:

| Bearing Type and Cage Design | Typical Limiting Speed Range (RPM) | Notes on Lubrication and Load Impact |

|---|---|---|

| Cylindrical Roller, 1 Piece Brass Cage | Several hundreds to thousands | Best speed with good lubrication |

| Cylindrical Roller, 2 Piece Brass Cage | Hundreds to low thousands | Needs oil for high speeds |

| Cylindrical Roller, Full Complement | Tens to low hundreds | Lower speed, more rollers, more heat |

| Tapered Roller, Pin Type Cage | Hundreds | Can go at moderate to high speeds |

| Spherical Roller, Brass Finger Cage | Tens to low hundreds | Moderate speed limits |

You should always use the bearing within the speed range for your load and lubrication.

Environment

The place where the bearing works matters a lot. High heat makes parts grow and breaks down oil. Cold makes oil thick and causes more friction. Dust, dirt, and water can get inside and wear out the bearing. Shaking from bad alignment or moving machines adds stress and makes the bearing wear out faster.

Pick heavy duty roller bearings, heavy duty track rollers, or heavy duty rollers with bearings made for your environment. Use seals to keep out dirt and pick oil or grease that works for your temperature.

Note: Taking care of your bearing and picking the right one helps it last longer, even in hard places.

If you need help picking a bearing for heavy loads, double row bearing, or double row tapered roller bearing, you can ask TFL Bearings. We can help you find the best one for your job.

Heavy Duty Roller Bearings Types

When you pick heavy duty roller bearings, you should know the different types. Each type is good for certain jobs. Some help with misalignment. Others are best for high radial or axial loads. The table below shows a quick summary:

| Bearing Type | Roller Shape | Main Load Direction | Key Features & Applications |

|---|---|---|---|

| Spherical Roller | Barrel | Radial & Axial | Self-aligning, handles misalignment, heavy loads, used in mining, wind turbines, gearboxes |

| Tapered Roller | Cone | Radial & Thrust | Handles combined loads, adjustable preload, used in vehicles, gearboxes, construction |

| Cylindrical Thrust Roller | Cylinder | Axial | High axial load capacity, easy maintenance, used in heavy machinery, marine, turbines |

| Heavy Duty Track Rollers | Varies | Radial | Supports heavy loads, smooth movement, used in cranes, conveyors, industrial machinery |

| Double Row/Double Roller | Varies | Radial & Axial | Higher load capacity, stability, used in heavy-duty, high-load applications |

Spherical Roller Bearings

Spherical roller bearings are great for heavy loads and misaligned shafts. They have two rows of barrel-shaped rollers and a curved ring. This shape lets them take both radial and axial loads. They can handle misalignment up to about 2 degrees. This helps them last longer in tough places like mines and construction. You often find these bearings in gearboxes and wind turbines. Some new models have smart sensors to check how they work.

Tip: Pick spherical roller bearings if your shaft bends or is not straight.

Tapered Roller Bearings

Tapered roller bearings are good for both radial and thrust loads. Their cone-shaped rollers spread the load out. This lowers friction and heat. You see these bearings in car wheels and farm machines. They work well in heavy jobs at medium speeds. Double row tapered roller bearing types can hold even bigger loads. They also help cut down on shaking, so they are used in rolling mills and big trucks. Always use the right oil or grease to make them last.

- Tapered roller bearings are strong and last long in hard places.

- They do not like misalignment, so you must install them carefully.

Cylindrical Thrust Roller Bearings

If your machine has strong axial forces, use cylindrical thrust roller bearings. They have a big contact area and special roller shape. This lets them carry heavy axial loads well. You can find these bearings in motor shafts and ships. They come apart easily, so fixing them is simple. Good seals and oil keep dirt out and help them last longer.

Heavy Duty Track Rollers

Heavy duty track rollers help move and guide heavy loads in machines. You use them in cranes, gantries, and conveyor belts. These rollers make movement smooth and lower friction. They also keep things lined up right. Heavy duty rollers with bearings are made to last and hold a lot of weight. They are very important in tough work areas.

| Application Area | Function |

|---|---|

| Industrial Machinery | Smooth movement, heavy load support, precise alignment |

| Heavy Transportation Systems | Stable movement for cranes and gantries, operational safety |

| Construction Equipment | Load stability and durability for cranes, excavators, and lifting machinery |

Double Row and Double Roller Bearings

Double row bearing and double roller bearing types have two rows of rollers. This makes them stronger than single row bearings. You use these in heavy jobs where you need more strength and longer life. Double row spherical bearings can handle very hard work and spread out the stress. This helps them last longer. They are harder to put in and take care of, but they work better and last longer in factories.

Note: Double row bearings and double row tapered roller bearing types are best for jobs that need to hold a lot of weight and last a long time.

If you want help picking the right heavy duty roller bearings, you can ask TFL Bearings. We can help you choose the best one for your job.

Key Selection Factors

Material

Picking the right material helps your bearing last longer. If the bearing rusts, it can break and stop working early. Wet, salty, or chemical places need bearings that do not rust. Stainless steel makes a shield and works well in water or with chemicals. Ceramics like silicon nitride do not react with chemicals and last in tough spots. Chrome steel is strong and hard to wear out, but it needs oil or a cover to stop rust. The table below shows how each material works:

| Bearing Material | Durability Characteristics | Corrosion Resistance | Typical Applications and Notes |

|---|---|---|---|

| Carbon Steel | Strong and hard to wear out | Not good in wet or chemical places | Used for many things, but not good for wet or chemical areas |

| Stainless Steel | Strong and does not wear out fast | Very good at stopping rust | Used in places with water or chemicals, like boats or factories |

| Chromium Steel | Very hard and strong | Not great at stopping rust | Used in cars and planes, needs a cover to stop rust |

| Bronze | Cheap, smooth, and does not wear out fast | Okay at stopping rust | Used in simple bearings, sometimes mixed with other metals to stop rust |

| Composite Materials | Stops rust well, slides easily | Very good at stopping rust | Used in water or chemical places, mixes metals and plastics for less friction |

| Ceramic (Silicon Nitride, Silicon Carbide) | Does not wear out, handles heat and rust well | Very good at stopping rust | Used in fast or tough jobs, light and does not get hot easily |

Tip: For tough jobs, pick stainless steel or ceramic bearings so they last longer.

Lubrication

Lubrication keeps your bearing safe from heat and rubbing. You need to use the right oil or grease for your job. For heavy and fast work, use special oils or greases with EP additives. Lithium grease works for most heavy duty roller bearings. Calcium grease protects against bumps and shaking. Oil is best for fast bearings because it cools them down. Grease is better for heavy loads and keeps dirt out. Polyurea and synthetic greases work in hot places and last longer. Always check your bearing and add more oil or grease when needed.

- Grease is used for heavy duty track rollers and heavy duty rollers with bearings.

- Oil is best for double row bearing and double roller bearing types when they spin fast.

- Add more oil or grease if your bearing works in dirty or rough places.

Mounting and Fit

Mounting and fit help your bearing work right. The shaft and housing must be the right size. If it is too tight, the bearing gets hot. If it is too loose, the bearing moves and wears out. Use ABMA or ISO rules to pick the fit. For heavy duty roller bearings, the ring that spins with the load should fit tightly. The other ring should have a little space. When you put in the bearing, heat the inside ring to make it bigger for the shaft. Use C3 or C4 clearance for fast or heavy jobs. Always use the right fit codes, like h5, k6, or H7, for best results.

Maintenance

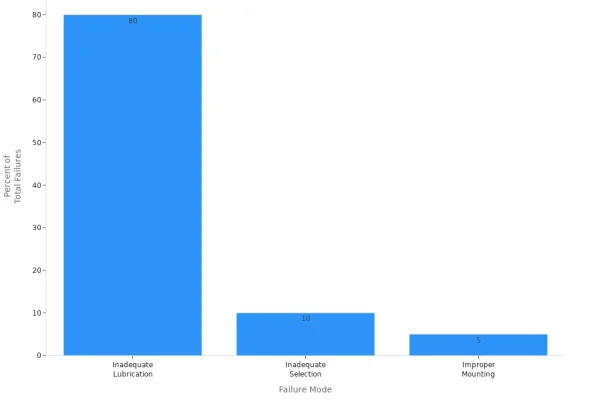

Taking care of your bearing helps it last longer. Make a plan to check and clean it often. Look for damage, rust, or dirt. Use vibration tools to find problems early. Clean the bearing with the right tools and change broken parts. Use the right oil or grease and write down what you do. Teach your team how to handle bearings the right way. The chart below shows why bearings break and how to stop it:

Note: Most bearings break because of bad oil, wrong choice, or bad mounting. Good care and picking the right bearing help stop these problems.

If you need help picking or caring for heavy duty roller bearings, double row tapered roller bearing, or double roller bearing, you can ask TFL Bearings. We can help you find the best one for your job.

Choose the Right Bearing for Your Application

Selection Checklist

Picking the right bearing means following clear steps. This checklist helps you avoid mistakes and keeps your machines working well:

- Identify Load Type and Magnitude

Find out if the load is radial, axial, or both. Measure how strong and which way the force goes. This helps you pick the right bearing. - Evaluate Dynamic and Static Load Requirements

Check the loads when the machine moves and when it stops. This makes sure the bearing will not break under pressure. - Determine Operating Speed

Learn the normal and top speeds. Make sure the bearing can handle these speeds without getting too hot or wearing out. - Assess Environmental Conditions

Look at things like heat, dust, water, and shaking. Pick heavy duty roller bearings or heavy duty rollers with bearings that can work in tough places. - Calculate Bearing Dimensions

Measure the hole size, outside size, and width. Make sure the bearing fits your shaft and housing. - Check Compatibility with Shaft and Housing

Make sure the bearing matches the shaft and housing sizes. A good fit stops misalignment and early failure. - Select Material and Design

Choose the right material, like stainless steel or ceramic, for your needs. Pick double roller bearing, double row bearing, or double row tapered roller bearing if you need extra strength. - Set Radial Clearance or Preload

Adjust the space or tightness to lower shaking and help the bearing work better. - Review Fit Tolerances and Mounting Methods

Use the right fit and way to put in the bearing. This helps stop damage during setup.

Tip: Always use the right oil or grease and follow the maker’s care tips. Bad lubrication is a big reason bearings break.

You can also use this table to check each step and what to think about:

| Step | Evaluation Criteria | Key Considerations |

|---|---|---|

| 1 | Bearing Type | Check how strong and which way the load goes; make sure it fits in the space. |

| 2 | Bearing Arrangement | Pick one or more bearings; make sure they can handle the loads and movement. |

| 3 | Dimensions and Service Life | Make sure the bearing fits and lasts as long as you need. |

| 4 | Speed, Accuracy, Fits, Clearance | Check if the bearing can go fast, run smoothly, and has the right fit and space. |

| 5 | Preload and Rigidity | Make sure the tightness keeps the bearing stiff and cuts down on shaking. |

| 6 | Lubrication and Stability | Make sure the oil or grease keeps the bearing running well for a long time. |

| 7 | Surrounding Components | Look at how the bearing works with seals, housings, and oil or grease for best results. |

| 8 | Mounting and Maintenance | Think about how easy it is to put in, take out, and check the bearing. |

Common Mistakes to Avoid

People often make mistakes when picking and putting in bearings. You can avoid these problems:

- Using the wrong oil or grease or not adding it on time.

- Not following what the maker says.

- Skipping regular checks, which lets dirt in and causes early failure.

- Using bad ways to put in or take out bearings, which can break them.

- Forgetting to check important things like load, speed, and where the bearing will work.

Note: Always check what your machine needs and use the right tools to put in the bearing. This helps you get the right bearing and makes it last longer.

When to Consult an Expert

Sometimes you need to ask a bearing expert for help. You should get advice when:

- Your machine moves slowly, rocks back and forth, or only turns partway, like in wind turbines, cranes, or gun mounts.

- You need special changes or have strict size and weight rules.

- You must meet industry rules, like API Standard 610 for oil and gas pumps.

- You need to balance design, how well it works, and cost.

- You have hard problems with load, speed, or the place where the bearing will work that normal bearings cannot solve.

Engineers and bearing experts use their skills to compare choices and do math for loads and how long the bearing will last. They can help you pick the best heavy duty track rollers, heavy duty roller bearings, or double row tapered roller bearing for your job.

When picking an expert, look for these things:

- Finished special training in bearings, how to put them in, and how to care for them.

- Real experience with heavy duty rollers with bearings and similar jobs.

- Certifications like ISO 9001 or CE marking, which show they care about quality and rules.

- Awards or training from trusted makers or industry groups.

Tip: Experts with the right training and certificates can help you pick the right bearing, stop costly breakdowns, and make sure you follow safety and quality rules.

If you need help picking a bearing or want to be sure you have the right one, ask us. At TFL Bearings, I am ready to help you find the right bearing for your job, whether you need double roller bearing, double row bearing, or heavy duty track rollers. Contact us for expert help and good answers.

Picking the right bearing means you need to know your load, speed, and where it will work. Always pick a bearing that fits your job. Use the checklist to check load, speed, fit, and what it is made of. People who work with machines say that picking and caring for bearings the right way stops them from breaking early. This also helps your machines work longer and saves money.

- For hard jobs, use bearings like heavy duty track rollers, heavy duty rollers with bearings, double roller bearing, double row bearing, or double row tapered roller bearing.

- Check your bearings often and put them in the right way so they last longer.

If you want help, you can contact TFL Bearings. I can help you find the best bearing for your job.

FAQ

What is the difference between a bearing and a roller bearing?

A bearing helps moving parts slide with less friction. A roller bearing uses rollers, like cylinders or cones, to hold heavy loads. Roller bearings are picked for machines that need to carry more weight or last longer.

When should you use heavy duty roller bearings?

Use heavy duty roller bearings when your machine has big loads or works in rough places. These bearings are good for construction, mining, and heavy machines. They last longer and can hold more weight than regular bearings.

How do you select the right bearing for high-speed applications?

Check the speed rating for each bearing type. Pick a bearing that matches your machine’s speed. Use the right oil or grease to keep it cool. For fast machines, double row bearing or double roller bearing types are often best.

What are the benefits of double row tapered roller bearing designs?

Double row tapered roller bearing designs can hold more weight and give better balance. Use them when you need to handle both sideways and end-to-end loads. These bearings help your machine run smoothly and last longer.

Where do you use heavy duty track rollers and heavy duty rollers with bearings?

Heavy duty track rollers and heavy duty rollers with bearings are used in cranes, conveyors, and big machines. These bearings help guide and support heavy loads. They make sure your equipment moves smoothly and stays lined up.

Need help picking the right bearing? At TFL Bearings, I can help you find the best answer for your job. Contact me for expert advice and help.