A spherical roller bearing has rollers shaped like barrels. These rollers help lower friction and support spinning shafts. This bearing can adjust itself if the shaft is not straight. It still works well even if the shaft is misaligned. Many industries use this design to handle heavy loads. It also helps with shock and vibration in hard conditions. The worldwide market for spherical roller bearings was $5.32 billion in 2024. The market keeps growing because more wind turbines, electric vehicles, and machines need them.

Key Takeaways

- Spherical roller bearings have rollers shaped like barrels. The outer ring is curved. This helps them adjust if the shaft is not straight.

- They can hold heavy loads very well. They also lower friction. This helps machines work better and last longer.

- The two rows of rollers spread the load out. This makes the bearing strong and steady in hard situations.

- These bearings are good for machines with shocks and vibrations. They also help when things do not line up right, like in wind turbines and big machines.

- Picking the right type, seals, and grease is important. This helps spherical roller bearings work well and last a long time.

What Is a Spherical Roller Bearing

Definition

A spherical roller bearing is a kind of rolling-element bearing. The outer ring has a curved inside surface. There are two rows of rollers shaped like barrels between the rings. These rollers are thick in the middle and thin at the ends. This shape lets the bearing hold both radial and axial loads. The bearing can also adjust if the shaft is not straight. Groups like ISO and ANSI set rules for spherical roller bearings. They describe the special shape and how the bearing can handle misalignment.

Spherical roller bearings can deal with shaft changes and misalignment because of the curved outer ring. They have two rows of barrel-shaped rollers set at different angles. The rollers move on separate tracks inside and one curved track outside. This design helps the bearing hold heavy loads and stay steady even if the shaft is not straight.

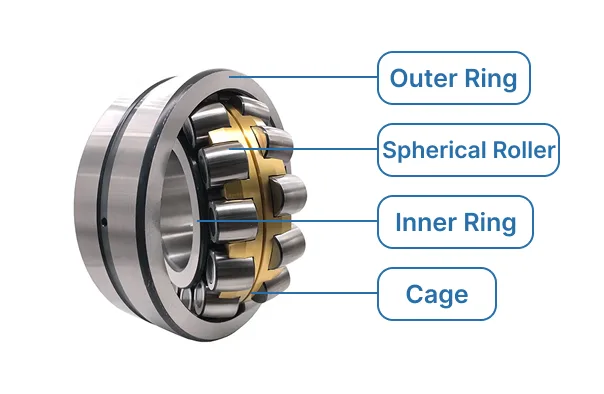

The main parts of a spherical roller bearing are:

- Inner and outer rings: These are made from strong steel. The rings have curved tracks for self-alignment and strength.

- Rollers: These are barrel-shaped and set in two rows. They are made from tough steel or ceramic to last longer.

- Cage: This part holds and guides the rollers. It can be made from steel, brass, or polyamide.

How It Works

Spherical roller bearings work because they can align themselves. The curved outer ring lets the inner ring and rollers tilt. This means the bearing can adjust if the shaft bends or moves. The barrel-shaped rollers roll smoothly on the curved track. This lets the bearing handle both still and moving misalignment.

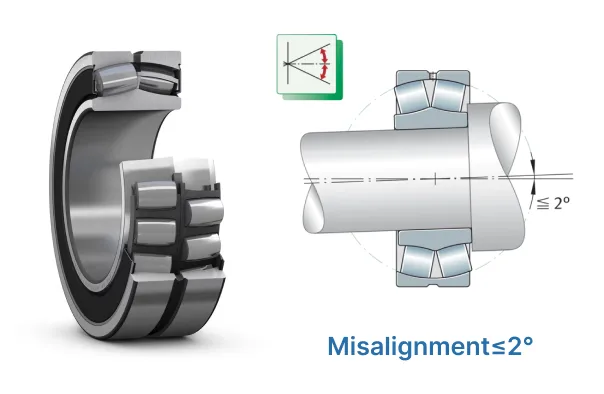

Most spherical roller bearings can handle about ±2 degrees of misalignment. This is better than other bearings like tapered roller bearings, which need perfect alignment. The self-aligning feature makes spherical roller bearings good for machines where perfect alignment is hard.

The two rows of rollers help the bearing carry big radial loads and some axial loads both ways. The rollers move on different tracks inside and share one curved track outside. This spreads the load and lowers wear.

The self-aligning system works like a ball-and-socket joint. It lets the bearing turn and tilt at the same time. This helps the bearing last longer and work well in tough places.

Spherical roller bearings are special because they hold heavy loads, lower friction, and keep working even if the shaft is not straight. Their self-aligning feature and strong build make them useful in many industries.

Key Features of Spherical Roller Bearings

Dual-Row Design

Spherical roller bearings have two rows of barrel-shaped rollers. These rollers sit between an inner ring and a curved outer ring. The two rows help the bearing hold both radial and axial loads. Flanges or guide rings keep the rollers in the right spot. This setup spreads the load over more rollers. It makes the bearing stronger and more stable. The cage keeps the rollers in place. It also lets oil or grease reach all parts for smooth movement. Most rings and rollers are made from high-grade chromium steel. The cages can be brass, steel, or polymer. Some bearings have a groove and holes for better lubrication. This design helps the bearing carry heavy loads and last longer.

Misalignment Handling

Spherical roller bearings can handle misalignment better than most bearings. The curved outer ring lets the inner ring and rollers tilt if the shaft bends. Most bearings in this group can adjust for misalignment from 1 to 2.5 degrees. This helps the bearing work well even if the shaft or housing is not perfect. The self-aligning shape spreads the load and lowers stress. This means the bearing can keep running smoothly, even if the machine frame twists. The ability to handle misalignment helps stop early failure and keeps machines working longer.

Spherical roller bearings keep working even when the shaft or housing changes shape. This makes them a top choice for machines that face tough conditions.

Load Capacity

Spherical roller bearings are made to support high loads. The two rows of barrel-shaped rollers let the bearing carry heavy loads in both directions. The load spreads evenly across all rollers. This increases stability and lowers wear. These bearings can also absorb shocks and vibrations better than cylindrical roller bearings. The strong design and special roller shape help the bearing last longer, even in harsh places. Spherical roller bearings often work where machines face heavy impacts or need to hold high loads every day. Their load carrying ability makes them great for mining, construction, and heavy industry.

Benefits of This Bearing

Reduced Friction

Spherical roller bearings help machines move with less friction. The barrel-shaped rollers roll easily between the rings. This shape keeps friction low, even if the shaft is bent. The coefficient of friction is about 0.0020, which is very low.

| Bearing Type | Coefficient of Friction (μ) |

|---|---|

| Spherical Roller Bearing | Approximately 0.0020 |

Most rolling bearings have friction from 0.0010 to 0.0050. These numbers show that spherical roller bearings help machines use less energy. Machines with these bearings spin smoothly and quietly. Less friction means less heat and less damage. This helps the bearing work better and last longer.

Spherical roller bearings lower friction, so less energy is wasted. This also means less fixing is needed and machines last longer.

Durability

Spherical roller bearings can last a long time, even in hard places. With good care, they can work up to 100,000 hours under heavy loads.

| Operating Condition | Minimum L10 Life (Hours) |

|---|---|

| Continuous 24 hour operation | ~60,000 |

| Continuous 24 hour operation, reliability important | ~100,000 |

Many things make these bearings strong. The self-aligning design lowers friction and stress inside. Strong materials and coatings protect from heat, dust, and water. The rollers spread force evenly, so the bearing lasts longer. These features help the bearing work well in tough places.

Self-aligning design lowers wear.

Strong materials stop shock and shaking.

Special coatings keep out rust and dirt.

Even force helps the bearing last longer.

Comparison with Other Bearings

Spherical roller bearings are better than many other types. They lower friction more, even if the shaft is bent. The table below shows how they compare to other bearings.

| Feature | Spherical Roller Bearings | Tapered Roller Bearings | Ball Bearings |

|---|---|---|---|

| Radial Load Capacity | Very high | High | Lower |

| Axial Load Capacity | Moderate | High | Moderate |

| Misalignment Tolerance | High | Low | Low |

| Friction | Low | Moderate | Very low |

| Durability | High | High | Moderate |

Spherical roller bearings lower friction and hold heavy loads. They also work well if the shaft is not straight. Ball bearings have less friction but cannot hold heavy loads or handle misalignment. Tapered roller bearings need the shaft to be straight and do not lower friction as much. For machines that need to work well and last long, spherical roller bearings are often the best pick.

Types of Spherical Roller Bearings

Standard Types

Standard spherical roller bearings are used in many big machines. They have two rows of barrel-shaped rollers inside. The open design lets people check and add grease easily. Most standard bearings have a cylindrical or tapered bore. These bearings can hold big radial loads and some axial loads. Factories use them in mining, steel plants, and paper machines. Some types have just one row for lighter loads. Others have two rows and a center flange for better work.

- Typical applications:

- Mining machinery

- Steel mills

- Wind turbines

- Paper processing equipment

Standard spherical roller bearings are good for machines that carry heavy loads and need to handle some shaft misalignment.

Sealed and Split Types

Sealed spherical roller bearings have strong rubber seals. These seals keep out dirt and water. The seals also help keep grease inside the bearing. This means less work is needed to take care of them. Sealed bearings can run faster and stay cooler than open ones. They last longer in dirty or wet places like farms or building sites.

Split spherical roller bearings come in two parts. This makes them easy to put in or take out. Workers do not have to take apart the whole machine to change the bearing. Big presses and conveyors often use split bearings.

- Benefits of sealed and split types:

- Less maintenance

- Longer service life

- Easier installation

Application-Specific Types

Some spherical roller bearings are made for special uses. These bearings have features for certain jobs or machines. Some have extra-strong inner rings for hot cylinders. Others have special coatings to stop rust or dirt. Spherical roller thrust bearings can hold higher thrust loads and keep alignment.

- Common uses:

- Crushers and vibrating screens

- Large industrial fans

- Wind turbine main shafts and gearboxes

- Marine propulsion systems

- Automotive suspension and steering

Application-specific bearings help machines work better in tough or special places. Engineers pick these bearings to fix special problems in their fields.

Applications of Spherical Roller Bearings

Heavy Machinery

Many industries use these bearings in big machines. Crushers, conveyors, and rolling mills need them for heavy loads. These bearings help absorb shock and keep machines running. The dual-row design spreads force over many rollers. This helps machines work smoothly, even if the load changes. Factories pick these bearings because they last long and need less fixing. In mining and construction, machines face dust, dirt, and hard hits. The strong build helps these bearings keep working in tough places.

Heavy machines need bearings that can take high pressure and sudden shocks. Spherical roller bearings do this with their strong build and ability to adjust if things are not lined up.

Main Shafts

Main shafts in wind turbines and gearboxes face high loads. These shafts can bend or move, which is hard for other bearings. Spherical roller bearings work well because they handle misalignment and keep the shaft steady. The table below shows how different bearings work for main shafts:

| Feature | Spherical Roller Bearings | Ball Bearings | Cylindrical Roller Bearings | Tapered Roller Bearings |

|---|---|---|---|---|

| Load Capacity | High radial and axial | Lower | High radial, lower axial | High radial and axial |

| Misalignment Handling | Excellent | Poor | Limited | Fair |

| Durability | Very durable | Less durable | Durable (radial only) | Very durable |

| Axial Load Handling | Effective | Limited | Limited | Excellent |

| Friction | Moderate | Low | Moderate | Moderate |

| Common Use Cases | Wind turbines, crushers | Motors, fans | Gearboxes, pumps | Automotive, axles |

Wind turbines need bearings that can take thrust and bending. Spherical roller bearings do this, even if the load is not even. New types, like asymmetric bearings, help share the load and lower heat. These changes help the bearing last longer and make the turbine work better.

Harsh Environments

Bearings often work where there is dust, water, or heat. Spherical roller bearings have a tough design to keep working in these places. Special seals and coatings protect them from dirt and water. Some bearings use strong steel or molded-oil seals to block dust and water. These features help the bearing last longer in mining, cement, or steel plants.

To keep bearings working in tough places, workers should follow these steps:

- Use seals to block dust and water.

- Pick stainless steel or ceramic bearings for wet places.

- Use the right grease for the job.

- Clean the bearing before putting it in.

- Do not use too much grease.

Spherical roller bearings can last up to ten times longer in dirty or wet places if they have the right seals and materials. This saves money and keeps factories running longer.

Spherical roller bearings are special because they can hold heavy loads. They also adjust if things are not lined up right. These bearings help machines work longer with less fixing. This saves money in hard places like factories or mines. When picking a bearing, people should think about the weight it must hold. They should also check how fast it will spin and where it will be used. Seals and grease are important to keep the bearing safe and smooth.

If you want to learn more, you can look at rules like ABMA 20 and ISO 492. You can also check catalogs from companies like SKF or Timken for help choosing the best bearing.

FAQ

What makes a spherical roller bearing different from other bearings?

A spherical roller bearing has rollers shaped like barrels. It also has a curved outer ring. This special shape lets it line up by itself. It can handle when the shaft is not straight. It also holds heavy loads better than many other bearings.

How does the self-aligning feature help in machines?

The self-aligning feature lets the bearing move if the shaft bends. It can also adjust if the shaft shifts. This helps the bearing work well for a long time. It lowers the chance of breaking early. Machines can keep working even if the shaft is not straight.

Why do industries choose spherical roller bearings for heavy loads?

Industries use spherical roller bearings because they hold heavy loads. The two rows of rollers help spread the weight. These bearings lower friction and work well in hard jobs. That is why they are picked for tough work.

Can spherical roller bearings reduce friction in harsh environments?

Yes. Spherical roller bearings lower friction with their rolling parts. The self-aligning design helps them work in dust or water. This keeps machines running longer. It also means less fixing is needed.

What should engineers consider for optimal performance?

Engineers should look at the load, speed, and where it will be used. They need to pick the right bearing type. They should use good seals and the right grease. This helps the bearing work well and last a long time.