Modern electric motors are increasingly exposed to electrical stresses caused by variable frequency drives, high switching frequencies, and complex power systems. While these technologies improve energy efficiency and speed control, they also introduce unwanted electrical currents that can damage internal motor components. One of the most vulnerable parts of a motor is the bearing system. This is where insulated bearings for motors play a critical role.

Electrically insulated bearings are designed to prevent stray electrical currents from passing through the bearing, thereby protecting it from electrical erosion and premature failure. Their use has become essential in many industrial, transportation, and power-generation applications where motor reliability and long service life are critical.

Looking for factory-direct solutions? At SDTFL, we specialize in manufacturing high-resistance insulated bearings that meet international standards. Check our Manufacturing Capabilities to see how we ensure quality at the source.

What Are Electrically Insulated Bearings

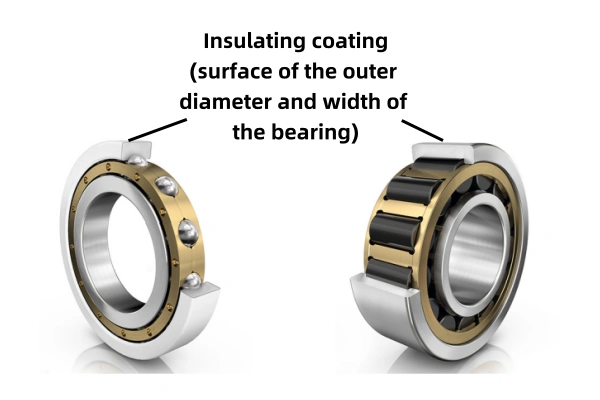

Electrically insulated bearings are rolling bearings designed with an insulating layer that prevents electrical current from passing between the inner and outer rings. This insulation breaks the electrical path that would otherwise allow current to flow through the bearing during motor operation.

The insulation is typically applied to the outer ring, inner ring, or both, depending on the application. Common insulation methods include ceramic coatings and hybrid designs that use ceramic rolling elements. These bearings are specifically engineered to maintain mechanical performance while providing high electrical resistance.

Why Electrical Currents Are a Problem in Motors

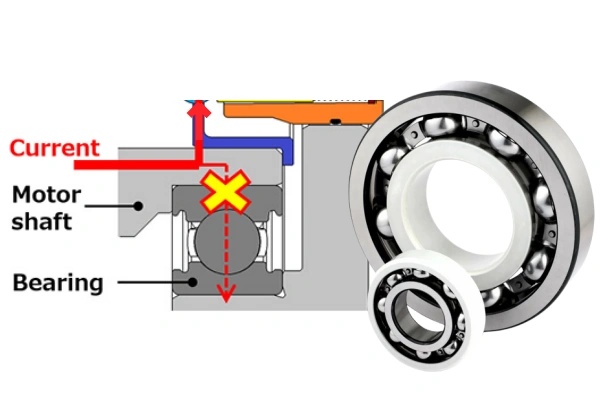

In electric motors, stray electrical currents can be generated due to voltage differences between the shaft and housing. These currents often result from inverter-driven systems, electromagnetic induction, or grounding issues. When such currents pass through a bearing, they can cause serious damage.

Electrical discharge through the bearing leads to a phenomenon known as electrical erosion. This process creates microscopic craters on the raceways and rolling elements. Over time, these craters develop into fluting patterns, increased vibration, noise, and ultimately bearing failure. Insulated bearings for motors are specifically designed to prevent this destructive process.

How Insulated Bearings for Motors Work

The key function of insulated bearings is to interrupt the electrical circuit between the motor shaft and the housing. This is achieved by applying a non-conductive layer to one or more bearing components.

Ceramic coatings, such as aluminum oxide, are commonly used because they offer high electrical resistance while maintaining good mechanical strength. Hybrid insulated bearings use ceramic rolling elements, which are naturally non-conductive, combined with steel rings. These design approaches effectively block current flow while allowing the bearing to function normally under mechanical loads.

Types of Electrically Insulated Bearings

Electrically insulated bearings are available in several configurations to suit different motor designs and operating conditions. Bearings with coated outer rings are commonly used because they are easy to install and effectively isolate the bearing from the housing.

Bearings with coated inner rings are used when shaft insulation is required. Hybrid bearings with ceramic rolling elements provide both electrical insulation and improved performance characteristics such as reduced friction and higher speed capability. Selecting the appropriate type depends on motor design, electrical environment, and load requirements.

Recommended Insulated Bearing Series for Your Motors

To ensure maximum protection, choose from our specialized product lines designed for variable frequency drives and high-voltage motors:

- Deep Groove Ball Bearings (Insulated Series): 6200, 6300 Series (VL0241/VL2071 Coatings). Ideal for standard electric motors and pumps.

- Cylindrical Roller Bearings (Insulated Series): NU, NJ, NUP Series. Designed for heavy radial loads in traction motors and wind energy generators.

- Hybrid Ceramic Bearings: Steel rings with Si3N4 ceramic balls. The ultimate solution for high-speed and extreme insulation requirements.

Need a specific size? As a manufacturer, we can customize insulation properties to fit your unique motor specs. View Our Full Product Catalog Here.

Key Benefits of Using Insulated Bearings for Motors

One of the primary benefits of insulated bearings for motors is protection against electrical corrosion. By preventing current flow through the bearing, these bearings significantly reduce the risk of raceway damage, fluting, and surface pitting.

Insulated bearings also extend bearing service life, which reduces maintenance frequency and downtime. They help maintain smoother motor operation by minimizing vibration and noise caused by electrical damage. In critical applications, this improved reliability translates directly into lower operating costs and increased equipment availability.

Invest in reliability. By sourcing directly from the SDTFL factory, you get premium electrical protection without the distributor markup. Request a Competitive Quote Today.

Applications That Require Electrically Insulated Bearings

Insulated bearings for motors are widely used in applications where electrical currents are present or likely to occur. AC motors driven by variable-frequency drives are among the most common use cases, as VFDs generate high-frequency voltage pulses that can induce shaft currents.

Traction motors used in railways, electric vehicles, and industrial transport systems also rely heavily on insulated bearings. In these applications, electrical isolation is essential to prevent damage caused by high operating voltages and regenerative braking systems.

Industrial power systems, wind turbines, pumps, compressors, and large generators also benefit from electrically insulated bearings. In these environments, insulated bearings help ensure long-term reliability under demanding electrical and mechanical conditions.

Electrically Insulated Bearings vs Standard Bearings

Standard bearings are designed purely for mechanical performance and offer no protection against electrical currents. When used in electrically active environments, they are highly susceptible to electrical erosion and premature failure.

Insulated bearings for motors provide the same mechanical load capacity and precision as standard bearings while adding electrical protection. Although insulated bearings may have a higher initial cost, they often deliver significantly better value by preventing early failures and reducing maintenance-related expenses.

Installation and Handling Considerations

Proper installation is essential to ensure the effectiveness of electrically insulated bearings. Care must be taken to avoid damaging the insulating layer during mounting. Scratches, cracks, or improper handling can compromise insulation performance and allow current leakage.

It is also important to ensure that only one electrical path exists within the motor system. If insulation is applied incorrectly or bypassed through other conductive components, the benefits of insulated bearings may be reduced. Following correct installation procedures helps maximize the effectiveness of insulated bearings for motors.

Need installation support? Our technical support team provides guidance on proper mounting to preserve insulation integrity. Call us at +86 15806631151 for immediate assistance.

Maintenance and Monitoring

While insulated bearings reduce electrical damage, they still require standard mechanical maintenance. Proper lubrication, contamination control, and alignment remain essential for long-term performance. Condition monitoring techniques such as vibration analysis and temperature monitoring can help detect early signs of mechanical wear.

In motors equipped with insulated bearings, monitoring helps verify that electrical erosion has been successfully eliminated and that the bearing is operating within acceptable parameters.

Cost Considerations and Long-Term Value

Although insulated bearings for motors typically cost more than standard bearings, their long-term benefits often outweigh the initial investment. Preventing electrical damage reduces the likelihood of unexpected failures, secondary component damage, and unplanned downtime.

For motors operating in inverter-driven or high-voltage environments, insulated bearings are often a necessary preventive solution rather than an optional upgrade. Their use supports higher reliability, improved performance stability, and lower total cost of ownership.

Electrically insulated bearings play a vital role in protecting motors from electrical corrosion and premature bearing failure. By preventing stray electrical currents from passing through the bearing, insulated bearings help maintain smooth operation, reduce vibration, and extend service life.

As inverter-driven systems and advanced motor technologies continue to evolve, the importance of insulated bearings for motors will only increase. Selecting the right insulated bearing solution is a key step toward achieving reliable, efficient, and long-lasting motor performance in modern industrial and power applications

Protect Your Motors with SDTFL Insulated Bearings

At SDTFL Bearings, we understand that motor reliability is the heart of your operation. We are not just a supplier; we are a dedicated manufacturer committed to solving the challenge of electrical erosion in modern machinery. Our electrically insulated bearings are engineered to withstand the harshest electrical environments, ensuring your VFDs and generators run smoother, longer.

Don’t let stray currents compromise your equipment. Partner with us for factory-direct quality and technical expertise that keeps your business moving.

- Ready to upgrade? Click here to browse our Insulated Bearing Inventory.

- Need a custom solution? Fill out our inquiry form and our engineers will design the perfect fit for your motor.

- Have urgent questions? Email us directly at info@sdtflbearing.com or call +86 15806631151.

Secure your motor’s future with SDTFL today.