You notice the difference between ball bearings when you compare a 4mm to a 10mm bearing. Each bearing size handles a unique set of challenges. The 4mm bearing fits into small devices where space matters most. The 10mm bearing supports heavier loads and larger machines. Size affects how long a bearing lasts and how well it performs. If you pick the wrong size, your bearing may not work as expected. Knowing why size matters helps you make better choices for your projects.

Key Takeaways

- 4mm ball bearings fit small spaces and work best in light machines needing precision and smooth movement.

- 10mm ball bearings handle heavier loads and last longer, making them ideal for strong, heavy-duty machines.

- Choosing the right bearing size ensures proper fit, better performance, and longer machine life.

- Using the wrong size bearing can cause early wear, poor fit, and machine failure.

- Expert advice and tools help you pick the best bearing size for your project and avoid costly mistakes.

Difference Between Ball Bearings

Ball Bearing Size

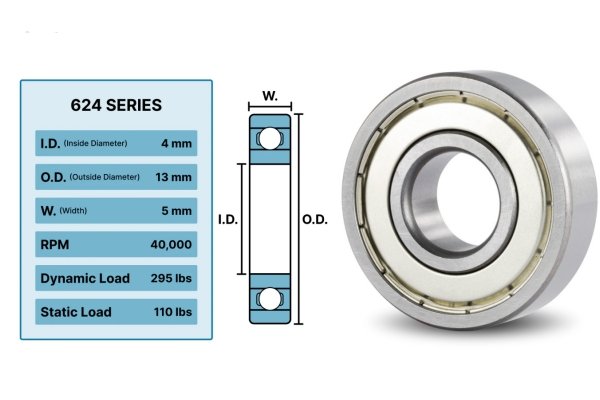

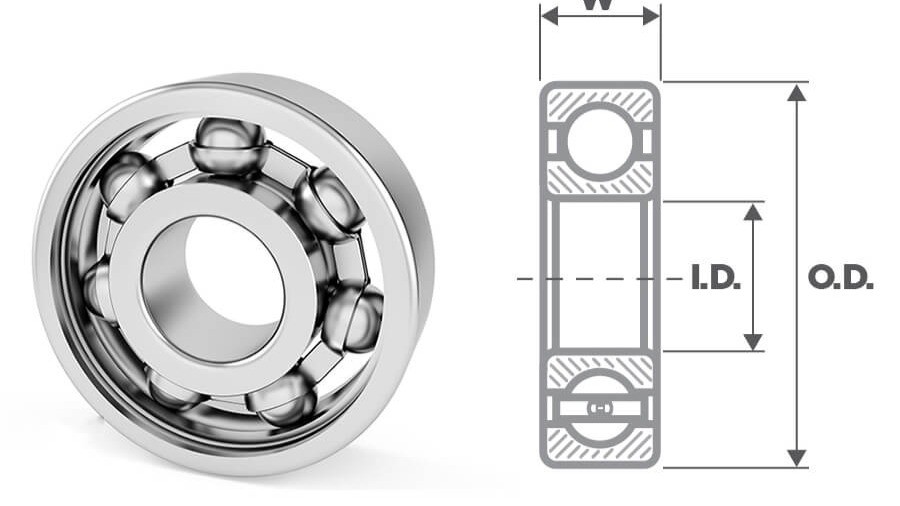

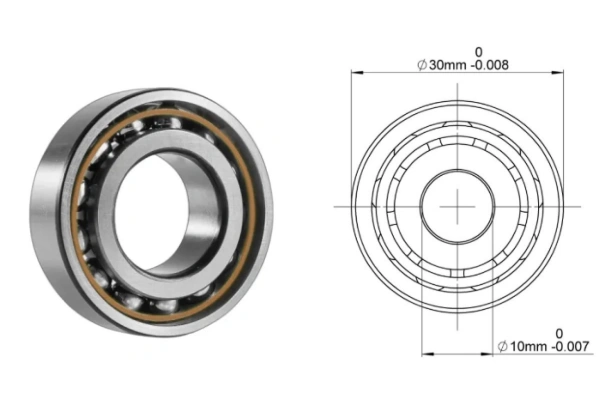

When you look at the difference between ball bearings, you first notice their size. Ball bearing size means three main measurements: the inner diameter (ID), the outer diameter (OD), and the width. You often see these numbers written as “ID x OD x W.” Manufacturers use these measurements to make sure each bearing fits its job. You can measure these with a caliper or ruler. Size charts help you match the right bearing to your needs.

Why does this matter? The size of a bearing decides where you can use it. Small bearings, like 4mm, fit into tight spaces. Large bearings, like 10mm, work in bigger machines. The difference between ball bearings in size changes how much weight they can hold and how long they last. Technical reports show that engineers spend a lot of time improving bearing design. They look at the shape, the cage, and even the coating to make sure each bearing works well for its size. You need to know the right size so your bearing fits and works as it should.

Load and Fit

The difference between ball bearings goes beyond just size. You also need to think about load and fit. Load means how much weight or force the bearing can handle. Fit means how well the bearing sits in its place. If you pick the wrong size, the bearing might not fit right or could fail under stress.

Let’s look at how size affects load capacity. Engineers use special formulas and tables to figure this out. Here is a simple table that shows how load factors change with bearing size:

Bearing Size (units) | Load Factor X | Load Factor Y |

|---|---|---|

Small (e.g., 25) | 2.30 | 0.19 |

Medium (e.g., 100) | 1.00 | 0.44 |

Large (e.g., 1000) | 1.00 | 0.44 |

You see that smaller bearings have higher load factors, which means they handle less weight before wearing out. Larger bearings can take more load and last longer. This is a key reason for the difference between ball bearings of different sizes.

Other factors that affect bearing size include the shaft and housing dimensions, the type of material, and the speed of the machine. If you use a bearing that is too small, it may deform or break under heavy load conditions. If the fit is too loose or too tight, the bearing may not spin smoothly or could wear out faster. Engineering studies show that the right fit and load are critical for bearing life and performance.

Tip: Always check the fit and load ratings before choosing a bearing. The difference between ball bearings often comes down to these details.

The difference between ball bearings is not just about how they look. It is about how they work under real-world conditions. You need to match the bearing size to the job, think about the load, and make sure the fit is correct. These are the main factors that affect bearing size and why you must pay attention to them.

4mm Ball Bearings

Applications

You often find 4mm ball bearings in places where precision matters most. These bearings work well in small devices that need smooth movement. Many engineers use them in compact machinery, robotics, and even medical tools. You see them in small motors, fans, and tiny gearboxes. Their small size lets you fit them into tight spaces where larger bearings cannot go.

A good example comes from applications that require both compact size and high precision. The Miniature Ball Bearing 624-ZZ, with its 4mm inner diameter, is commonly used in small electric motors, 3D printers, robotics joints, and precision instruments. Its double metal shields (ZZ) help protect against dust and debris while maintaining smooth rotation. These features make it ideal for tasks that demand low friction, high reliability, and consistent performance in limited space.

Benefits and Limits

You choose 4mm ball bearings when you want to save space and reduce weight. These bearings help you build lighter and more compact machines. They also spin with less resistance, which means less energy loss. If you work with electronics or small gadgets, you will notice how these bearings make everything run quietly and efficiently.

However, you must remember the limits of 4mm ball bearings. Their small size means they cannot handle heavy loads. If you put too much weight on them, they may wear out quickly or even fail. You also need to check the fit carefully. A loose or tight fit can cause the bearing to stop working as it should. In harsh environments, like those with lots of dust or moisture, these small bearings may need extra protection.

Tip: Always match the bearing size to your project’s needs. Using a 4mm bearing in the wrong place can lead to early failure or poor performance.

10mm Ball Bearings

Uses

You often see 10mm ball bearings in places where strength matters most. These bearings work well in heavy-duty equipment. You find them in power tools, industrial machines, and even in some automotive parts. When you need to move large parts or handle strong forces, you choose a 10mm bearing. This size gives you more support and stability.

Many factories use 10mm ball bearings in conveyor belts and assembly lines. These machines run for long hours and carry heavy loads. The larger bearing helps the machine run smoothly and last longer. You also see this bearing in electric motors and pumps. When you want your equipment to work without stopping, you need a bearing that can handle the job.

Note: If you work with machines that need to lift or move heavy items, you should always check if a 10mm bearing fits your needs.

Strengths and Drawbacks

A 10mm ball bearing gives you several advantages. The larger size means it can carry more weight. You get better durability and longer life from your machine. The bearing can handle more stress and heat. This makes it a good choice for tough jobs.

Here are some key strengths of 10mm ball bearings:

- High load capacity

- Strong resistance to wear

- Good performance in harsh environments

However, you should also know the drawbacks. A bigger bearing takes up more space. If your machine has limited room, the 10mm size may not fit. Larger bearings can also add extra weight to your design. Sometimes, a bigger bearing may not spin as fast as a smaller one. You need to balance speed and strength when you pick a bearing.

Tip: Always match the bearing size to your project. Using a bearing that is too large or too small can cause problems with performance and safety.

You choose a 10mm ball bearing when you want strength and durability. You must also think about space and speed. Picking the right bearing helps your machine work better and last longer.

Why Bearing Size Matters

Performance Impact

You need to understand why bearing size matters when you want your machines to work well. The size of a bearing changes how much load it can carry, how fast it can spin, and how much space it takes up. If you use a 4mm bearing, you get a compact part that fits into small devices. This small size helps you save space and reduce weight. However, a 4mm bearing cannot handle heavy loads. It works best in light-duty jobs where precision and smooth movement are important.

A 10mm bearing gives you more strength. You can use it in machines that need to carry heavy loads or run for long hours. The larger size lets the bearing handle more force and last longer. You may notice that bigger bearings sometimes spin slower than smaller ones. This happens because the extra weight and size create more friction. You must balance speed and strength when you choose a bearing.

| Bearing Size | Load Capacity | Speed | Space Needed |

|---|---|---|---|

| 4mm | Low | High | Small |

| 10mm | High | Medium | Large |

If you pick the wrong size, you risk poor performance. A bearing that is too small may wear out fast or break. A bearing that is too large may not fit or could slow down your machine. This is why bearing size matters for every project.

Choosing the Right Size

You face real risks if you do not choose the correct bearing size. Technical assessments show that the wrong size can cause loose or tight fits. These problems lead to heat, vibration, and early failure. Advanced tools, like vibration sensors and deep learning models, help experts spot these faults early. You can use manufacturer charts, calculators, and alignment tools to check your fit before you install a bearing. These steps help you avoid costly mistakes.

Tip: Always check the fit and load ratings before you install a bearing. A good fit keeps your machine running smoothly.

When you want to pick the right bearing, you should follow expert guidelines:

- Define your application and the environment where the bearing will work.

- Think about the type of load: Is it radial (sideways) or axial (straight down)?

- Check how fast the bearing needs to spin.

- Choose the right material, such as chrome steel or stainless steel, for your needs.

- Make sure the bearing fits the shaft and housing with the right tolerance.

- Use proper lubrication to keep the bearing cool and reduce wear.

- Follow best practices for installation, like cleaning the workspace and checking alignment.

You can use this checklist to help you decide:

- What is the load type and amount?

- How much space do you have for the bearing?

- What speed does your machine need?

- What environment will the bearing face (dust, water, heat)?

- What material works best for your job?

If you answer these questions, you will see why bearing size matters for your project. The right choice improves performance, saves money, and keeps your machines safe.

TFL Bearings

Product Range

You want a supplier that understands why different bearings matter for your project. TFL Bearings stands out because it offers a wide range of ball bearings for many uses. You can find both 4mm and 10mm bearings in our catalog. These bearings work well in robotics, aerospace, and medical devices. TFL Bearings designs thin-walled four-point angular contact ball bearings for high precision and reliability. You get bearings that fit tight spaces and still deliver strong performance.

- Thin section bearings are lightweight and perfect for small machines.

- High precision bearings, like the 71813 C P4, give you smooth and accurate movement.

- Special lubricants help each bearing last longer and work better in tough jobs.

- These bearings handle both radial and axial loads, so you can use them in many types of bearings.

- You get excellent running accuracy, which means less heat and less torque.

You see why TFL Bearings is trusted. The company makes sure each bearing meets strict standards. You get products that work well in demanding conditions.

Expert Support

Choosing the right bearing can be hard. TFL Bearings helps you make the best choice for your project. You get expert advice from their team. We guide you on which types of bearings fit your needs. You can ask questions and get answers fast. TFL Bearings offers:

- Professional technical support for picking the right bearing.

- Custom solutions for special projects.

- Guides and articles on bearing selection, lubrication, and maintenance.

- A large inventory for quick delivery.

- Quality control and engineering help for every order.

- Training and sales support if you need extra help.

You see why expert support matters. TFL Bearings gives you the tools and knowledge to avoid mistakes. You get help with both metric and inch sizes. If you need a special bearing, our team can help you find it. You can trust TFL Bearings to support you from start to finish.

Tip: If you feel unsure about which bearing to choose, reach out to TFL Bearings. Our experts can help you pick the right product for your job.

You now see why choosing the right size matters. The difference between 4mm and 10mm ball bearings affects how your machines work. You must think about load, fit, and where you will use each part. If you feel unsure, ask an expert for help. TFL Bearings can guide you so you make the best choice for your project.

Remember: The right size keeps your equipment safe and running well.

FAQ

Why does bearing size affect performance?

You see a direct link between bearing size and performance. A larger bearing handles more load conditions and lasts longer. A smaller bearing fits tight spaces but may wear out faster. You must match the size to your application for the best results.

Why is it important to choose the right ball bearing size?

You need the correct ball bearing size to avoid equipment failure. The wrong size can cause poor fit, extra friction, or early wear. You protect your machine and improve performance when you select the right size for your needs.

Why do different types of bearings exist?

You find many types of bearings because each one meets different load conditions and application needs. Engineers design them to handle specific speeds, loads, and environments. You must know the difference between ball bearings and other types to make the right choice.

Why do load conditions matter when selecting a bearing?

You must consider load conditions because they decide how much force your bearing will face. Heavy loads require larger or stronger bearings. Light loads allow you to use smaller bearings. You improve safety and performance by matching the bearing to the load.

Why bearing size matters for your project?

You see why bearing size matters when you look at the factors that affect bearing size. The right size ensures proper fit, smooth movement, and long life. You avoid costly repairs and downtime by choosing the correct bearing for your project.