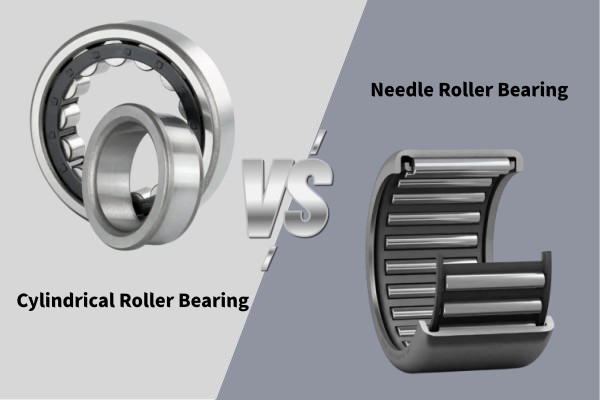

Choosing the right roller bearing directly impacts machine reliability, efficiency, and lifespan. Among radial roller bearings, engineers and procurement teams frequently compare cylindrical vs needle roller bearings because both are designed to handle high radial loads, yet they serve very different design goals.

While cylindrical roller bearings are known for strength, stiffness, and durability in heavy-duty machinery, needle roller bearings are valued for their extremely compact form and space-saving advantages. Understanding how these two bearing types differ in structure, performance, and application helps avoid incorrect selection and costly redesigns.

Understanding Cylindrical Roller Bearings

Cylindrical roller bearings use relatively large cylindrical rollers that maintain line contact with the raceways. This design allows them to support very high radial loads while keeping friction relatively low. The rollers are guided by ribs on the inner or outer ring, which provide stability during operation and help control roller movement at higher speeds.

These bearings are commonly supplied with both inner and outer rings and are available in multiple configurations. Some designs allow axial displacement between the shaft and housing, making cylindrical roller bearings suitable for applications where thermal expansion or slight misalignment may occur. Their robust construction makes them a preferred choice in industrial environments where reliability and long service life are critical.

SDTFL Factory Insight: Need high-rigidity solutions? We manufacture premium Cylindrical Roller Bearings (N, NU, NJ, NUP series) designed for heavy radial loads. Request our Factory Specification Sheet.

Understanding Needle Roller Bearings

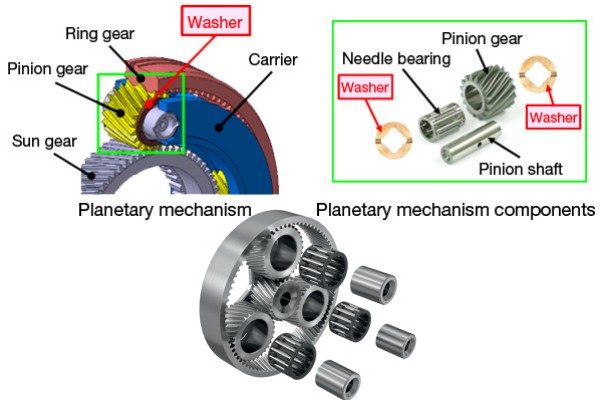

Needle roller bearings are a compact variation of cylindrical roller bearings, distinguished by their long, thin rollers. These needle-shaped rollers allow the bearing to carry relatively high radial loads while occupying minimal radial space. This makes needle roller bearings especially useful in compact machinery where standard bearings cannot fit.

In many designs, needle roller bearings operate without an inner ring, using the shaft surface directly as a raceway. While this reduces bearing size and weight, it places greater demands on shaft hardness, surface finish, and alignment. Needle roller bearings are therefore highly efficient but more sensitive to installation and operating conditions.

Compact Design Solutions: SDTFL produces high-precision needle roller bearings that meet strict tolerance standards, perfect for automotive and textile machinery. Explore our Needle Bearing Catalog.

Key Structural Differences

The most important difference in cylindrical vs needle roller bearings lies in their geometry. Cylindrical roller bearings have a thicker cross-section and larger rollers, resulting in higher stiffness and structural rigidity. Needle roller bearings, on the other hand, sacrifice thickness for compactness, using slender rollers to minimize space requirements.

Because of this structural difference, cylindrical roller bearings are more forgiving regarding mounting accuracy and shaft deflection. Needle roller bearings require tighter tolerances and better shaft preparation to achieve comparable service life.

Load Handling Characteristics

Cylindrical roller bearings are designed to support very high radial loads and are often chosen for heavy-duty uses. Their larger rollers spread the load evenly across the raceways, reducing stress points and enhancing fatigue resistance. Needle roller bearings also carry high radial loads relative to their size, but their total load capacity is usually lower. Because the rollers are thinner, they are more vulnerable to surface fatigue if loads go beyond the design limits. Therefore, needle roller bearings are best for moderate-load situations where space savings are more important than maximum load capacity.

Speed and Operating Performance

Speed capability is another important factor when comparing cylindrical vs needle roller bearings. Cylindrical roller bearings generally perform better at medium to high speeds due to stable roller guidance and controlled friction.

Needle roller bearings are typically used at lower to moderate speeds. At higher speeds, the long rollers can generate increased friction and heat, which may limit performance. For applications involving continuous high-speed rotation, cylindrical roller bearings are usually the safer and more reliable choice.

Sensitivity to Alignment and Shaft Quality

Cylindrical roller bearings are relatively tolerant of minor misalignment and shaft deflection, especially in designs that allow axial movement. This makes them suitable for large machines and systems where perfect alignment is difficult to maintain.

Needle roller bearings are much more sensitive to alignment errors. When used without an inner ring, the shaft must be precisely hardened and ground to act as a raceway. Any deviation in surface finish or alignment can significantly reduce bearing life. This sensitivity must be carefully considered during design and installation.

Typical Applications for Cylindrical Roller Bearings

Cylindrical roller bearings are widely used in heavy industrial equipment where load capacity and durability are top priorities. Common applications include gearboxes, electric motors, pumps, compressors, rolling mills, wind turbine gear systems, and machine tool spindles.

Their ability to handle high loads, resist fatigue, and operate reliably over long periods makes them ideal for continuous-duty and high-stress environments.

Typical Applications for Needle Roller Bearings

Needle roller bearings are commonly used in compact machinery and automotive systems where space is limited. Typical applications include transmissions, planetary gear sets, small compressors, construction tools, agricultural machinery, and lightweight industrial equipment.

They are also widely used in automation systems and mechanisms where designers need to reduce housing size and overall machine weight without sacrificing load capacity.

Cost and Design Trade-Offs

From a design perspective, needle roller bearings often offer cost and space savings, especially when eliminating the inner ring allows simpler housing designs. However, additional costs may arise from shaft hardening and precision machining requirements.

Cylindrical roller bearings usually have a higher upfront cost due to their larger size and robust construction. In return, they offer longer service life, higher reliability, and lower sensitivity to installation conditions, which can reduce total lifecycle cost in demanding applications.

Direct Factory Pricing: Cut out the middleman. SDTFL offers competitive factory-direct pricing for bulk orders of both bearing types. Get a Quick Quote Today.

How to Choose the Right Bearing Type

Selecting between cylindrical vs needle roller bearings depends on balancing load requirements, available space, operating speed, and installation conditions. Cylindrical roller bearings are the better choice when load capacity, stiffness, and durability are critical.

Needle roller bearings are ideal when space constraints dominate the design and loads are moderate. Engineers must also consider shaft quality, alignment accuracy, and expected service life before finalizing their selection.

Quick Reference: SDTFL Bearing Series Selection

To help you finalize your design, here are the corresponding series we manufacture:

- For Heavy Loads (Cylindrical):

- NU/N Series: Allows axial displacement, ideal for motors.

- NJ/NF Series: Handles unidirectional axial loads.

- NUP Series: Used for locating bearings.

- For Limited Space (Needle):

- HK Series: Drawn cup needle roller bearings (open ends).

- NK/NKI Series: Machined ring needle roller bearings (heavy duty).

- K Series: Needle roller and cage assemblies (requires hardened shaft).

Selection Assistance: Still undecided? Send your technical drawings to info@sdtflbearing.com and let our experts recommend the perfect series.

Common Selection Mistakes

A frequent mistake is choosing needle roller bearings in applications where shaft surface quality is inadequate, leading to rapid wear. Another common issue is oversizing cylindrical roller bearings in compact designs, which increases cost and weight unnecessarily.

Careful evaluation of operating conditions and design constraints helps avoid these issues and ensures optimal bearing performance.

Both cylindrical and needle roller bearings play important roles in modern machinery, but they serve different engineering priorities. Cylindrical roller bearings offer superior load capacity, stiffness, and speed capability, making them ideal for heavy-duty industrial applications. Needle roller bearings provide exceptional space efficiency and are best suited for compact designs with controlled operating conditions.

By understanding the differences between cylindrical vs needle roller bearings and aligning selection with machine requirements, engineers and buyers can achieve reliable performance, efficient design, and long-term cost savings.

Partner with SDTFL Bearings for the Perfect Fit

Whether your machinery demands the brute strength of Cylindrical Roller Bearings or the precision compactness of Needle Roller Bearings, making the right choice is crucial. At SDTFL Bearings, we are more than just a supplier—we are a dedicated factory manufacturer committed to producing high-performance bearings for the global market.

We understand the unique challenges of both heavy-duty and space-constrained applications. By sourcing directly from us, you gain access to expert engineering support, consistent quality control, and competitive B2B pricing.

Ready to optimize your machinery?

- Get a Factory Quote: Email us at info@sdtflbearing.com

- Technical Consultation: Call our experts at +86 15806631151.

- Start Your Order: Click here to view Our Full Product Catalog.

Let SDTFL Bearings provide the reliability and efficiency your business deserves. Contact SDTFL today!