You need to choose the right miniature ball bearings for your project to achieve precision and reliability. The correct bearing supports efficiency and boosts durability in high-precision equipment. When you choose a bearing, always check the load, speed, size, material, lubrication, and environment. These factors help you get the best performance from your bearings. High-quality bearings from TFL deliver miniature precision ball bearing solutions for demanding tasks. When you choose the right bearings, you improve reliability and durability. Trust TFL for miniature precision bearings and high precision bearings that last.

Tip: Always choose a bearing from TFL for high-quality bearings and unmatched support.

Key Takeaways

- Choose the right miniature ball bearing by checking load, speed, size, material, lubrication, and environment to ensure precision and durability.

- Match bearing types like standard, flanged, thrust, or extended inner ring to your project needs for best performance in different applications.

- Measure your shaft and housing carefully to select the correct bearing size and fit, which reduces vibration and extends bearing life.

- Use proper lubrication and maintenance to keep bearings running smoothly and prevent early failure or noise problems.

- Handle and install bearings with care, considering environmental factors like dust and moisture, to protect your equipment and improve reliability.

Types of Miniature Ball Bearings

Miniature ball bearings come in several types. Each type fits different applications. You need to know which type works best for your project.

Standard and Flanged Bearings

Standard bearings have a simple design. You can use them in many applications. These bearings have an inner ring, an outer ring, balls, and a cage. They work well in small motors, fans, and measuring tools. You often see them in scientific instruments and medical devices.

Flanged bearings have a flange on the outer ring. This flange helps you position the bearing easily. It also keeps the bearing from moving too much. Flanged bearings are common in robotics, 3D printers, and precision manufacturing. They help you get accurate results in your applications.

Note: Flanged and standard bearings support high precision and durability. Many companies use them in scientific and manufacturing applications because they last long and work well.

Extended Inner Ring and Thrust Bearings

Some bearings have an extended inner ring. This design gives extra support for axial loads. You can use these bearings when you have limited space but need strong support. Extended inner ring bearings are useful in medical pumps, lab equipment, and small gearboxes.

Thrust bearings handle loads that push along the shaft. You use them in applications where you need to support force in one direction. Thrust bearings are important in scientific tools, medical scanners, and manufacturing machines. They keep your equipment running smoothly.

Tip: Many medical devices, such as CT scanners, use special bearings. These bearings ensure quiet and precise operation. They also meet strict safety rules.

Here is a quick overview of where you might use each type:

| Bearing Type | Typical Applications |

|---|---|

| Standard | Small motors, fans, measuring tools |

| Flanged | Robotics, 3D printers, precision machines |

| Extended Inner Ring | Medical pumps, lab equipment, gearboxes |

| Thrust | Medical scanners, scientific tools, jacks |

You can find these bearings in many industries. Manufacturing, medical, and scientific fields all rely on these bearings for their applications. Companies often choose ceram ic hybrid bearings for demanding environments. These bearings last longer and resist wear.

If you want the best results for your bearing applications, choose the right type for your needs. TFL Bearings offers a wide range of miniature ball bearings for all your applications. Contact TFL Bearings to find the perfect solution for your project.

Key Factors to Choose A Miniature Ball Bearing

When you choose a bearing for your project, you need to look at several important factors. These key factors for engineers help you get the best performance, reliability, and fit for your application. This bearing selection guide will help you understand what to check before you make your decision.

Load and Speed

Load and speed are the first things you should consider in bearing selection. Load means the force your bearing will carry. You need to know if your application has a radial load (force from the side), an axial load (force along the shaft), or a combined load. Load capacity tells you how much force the bearing can handle without failing. If you use a bearing with too low a load capacity, it will wear out quickly.

Speed is just as important. High-speed applications need bearings that can spin fast without overheating or making noise. Miniature precision ball bearing designs allow for high-speed rotation with low noise and vibration. For example, you see these bearings in fan motors, spindle motors, and medical devices. Extra-miniature bearings work well in high-speed, high-precision tools like rotary encoders and dental handpieces. Flanged bearings help in high-vibration environments, such as scanner motors and card readers. Extra-thin bearings are great for places where you need minimal weight and thickness, but you must check their load capacity.

Tip: Always match the load and speed in bearing selection to your project’s needs. This ensures long life and top performance.

Size and Fit

Size and fit play a big role in how well your bearing works. You need to measure the inner diameter, outer diameter, and width of the space where you will install the bearing. Accurate measurements help you get the right fit. If the bearing is too loose or too tight, it can cause vibration, friction, and early failure.

Miniature precision bearings are made with extremely precise tolerances. This means the size is controlled down to the micrometer. When you select the correct miniature precision bearing, you make sure it fits perfectly in your shaft and housing. This perfect fit reduces friction, keeps the bearing aligned, and improves performance. Use tools like vernier calipers to measure the space. Always check the size chart from the manufacturer to match your needs.

A good fit also affects load capacity. Smaller bearings fit in tight spaces and work well in medical instruments and robotics. Larger bearings support higher loads but need more space. If you want high precision and reliability, always check the fit before you choose a bearing.

Lubrication and Maintenance

Lubrication keeps your bearing running smoothly. It forms a thin film that reduces friction, heat, and wear. You can use grease or oil, depending on your application. Grease is easy to use and seals the bearing well. Oil works better for high-speed or high-temperature bearings because it helps remove heat.

You need to follow a maintenance schedule. Over time, grease breaks down and needs to be replaced. The right schedule depends on the grease type, bearing size, speed, and environment. If you skip maintenance, your bearing may get noisy or fail early. Regular checks of temperature, vibration, and noise help you spot problems before they get worse.

Note: Abnormal noises like buzzing or screeching often mean you have the wrong lubricant or too much or too little of it. Always use the right type and amount of lubricant for your bearing.

Noise and Vibration

Noise and vibration can tell you a lot about your bearing’s health. High-speed applications need bearings that run quietly and smoothly. If you hear strange sounds, your bearing may have dirt, damage, or poor lubrication. Too much or too little lubricant can also cause problems.

You should monitor your bearing’s temperature. A stable temperature below 100°C means your bearing is working well. If the temperature rises, check the lubrication and installation. Condition monitoring helps you catch issues early and keep your bearing in top shape.

A quiet, low-vibration bearing means you have the right fit, good lubrication, and high precision. This leads to better performance and longer life for your equipment.

Remember: Choosing the right bearing, checking the fit, and keeping up with maintenance all help you get the best performance and reliability.

If you want to choose a bearing that meets your needs for load, speed, fit, and precision, trust TFL Bearings. Our miniature precision bearings and high precision bearings deliver top performance for high-speed applications. Contact TFL Bearings for expert advice and the best miniature precision bearings for your project.

Material Choices for Miniature Precision Ball Bearing

Choosing the right material for your miniature ball bearings makes a big difference in performance, durability, and high-speed operation. Each material has unique properties that help you match your bearings to your project’s needs.

Chrome Steel and Stainless Steel

You often see chrome steel and stainless steel in miniature bearings. Chrome steel offers high hardness, usually around 60 HRC, which means your bearings can handle heavy loads and high-speed rotation. This material gives you excellent performance and long durability in clean, dry environments. Chrome steel bearings work well in motors, gearboxes, and other high-speed machines.

Stainless steel bearings give you strong corrosion resistance. You can use them in wet or acidic environments, like medical devices or food processing equipment. Martensitic stainless steel reaches up to 63 HRC, so it also supports high-speed and heavy-duty tasks. Austenitic stainless steel stands out for its top corrosion resistance, making it a smart choice for harsh conditions.

Here is a quick comparison of common bearing materials:

| Material Type | Hardness (HRC) | Corrosion Resistance | Density (g/cm³) | Notes |

|---|---|---|---|---|

| Chrome Steel | ~60 | Low | ~7.8 | High hardness, best for dry environments |

| Martensitic Stainless Steel | Up to 63 | Moderate | ~7.8 | Good for medical and industrial bearings |

| Austenitic Stainless Steel | N/A | Highest | ~7.8 | Best for corrosive or wet environments |

Ceramic and Plastic Options

Ceramic bearings give you top performance in high-speed and high-temperature settings. These bearings weigh less than steel, so they spin faster and reduce friction. Ceramics resist wear and do not need much lubrication. You can use ceramic bearings in dental tools, scientific instruments, and other high-speed machines.

Plastic bearings are lightweight and resist chemicals. You can use them in low-load, low-speed applications where weight matters most. Plastic bearings do not rust, so they work well in damp or corrosive places. However, they do not match the hardness or durability of steel or ceramic bearings.

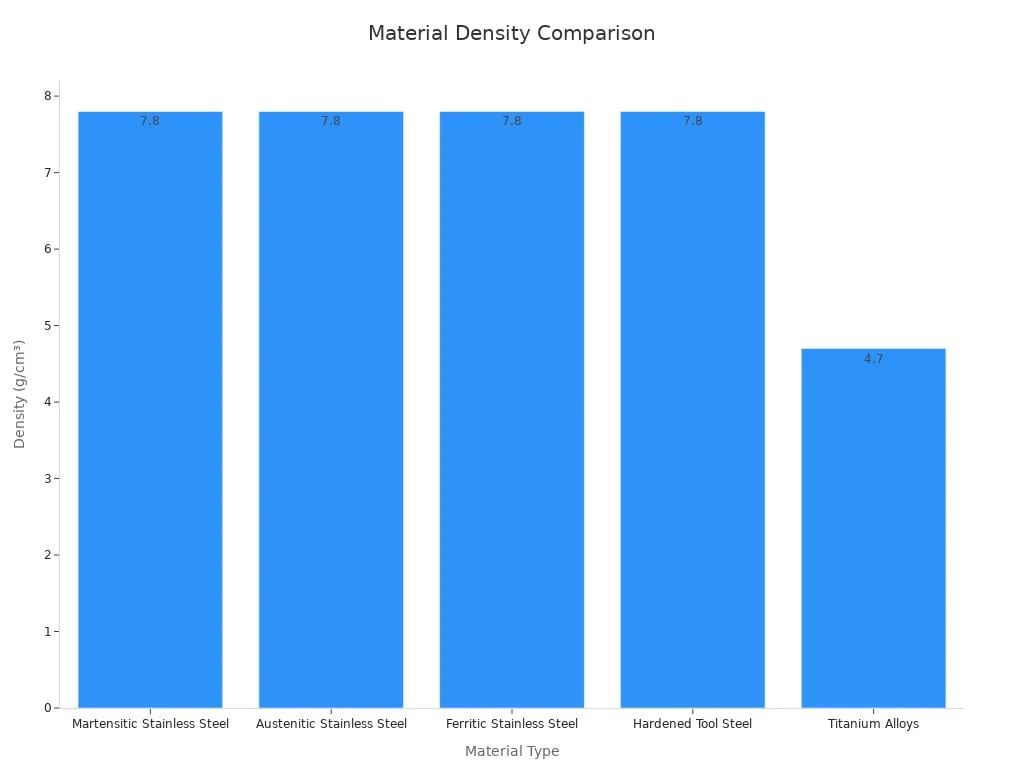

Take a look at this chart to see how the density of different materials compares:

When you choose bearings, think about your project’s environment and speed. For high-speed and heavy loads, chrome steel or ceramic bearings give you the best performance and durability. For wet or harsh environments, stainless steel or plastic bearings protect against corrosion. Always match the material to your needs to get the most from your bearings.

Tip: If you want expert advice or need help choosing the right miniature ball bearing, contact TFL Bearings for high-quality products and support.

How to Choose the Right Bearing Size

Selecting the right size for your bearings is one of the most important steps in any project. The correct size helps you get the best fit, smooth operation, and long-lasting performance. You need to look at the space in your equipment and the type of load you expect. This bearing selection guide will help you make the right choice.

3mm, 4mm, 6mm Selection

You often see 3mm, 4mm, and 6mm bearings in high-precision equipment. These sizes work well in many applications, such as robotics, medical devices, and small motors. Each size gives you a different balance of strength, speed, and fit.

- 3mm bearings: You use these when you have very limited space. They are light and allow for high-speed rotation. You often find them in small sensors, micro motors, and compact gearboxes. The small size gives you a tight fit in tiny spaces.

- 4mm bearings: These offer a good balance between strength and size. You can use them in small fans, precision tools, and lab equipment. The 4mm size gives you a secure fit and supports moderate loads.

- 6mm bearings: You choose these when you need more strength and a higher load capacity. They work well in larger motors, pumps, and scientific instruments. The 6mm size gives you a strong fit and handles more force.

Tip: Always check the space in your equipment before you pick a size. The right fit helps your bearings last longer and work better.

Here is a quick table to help you compare these common sizes:

| Bearing Size | Typical Use Cases | Fit Strength |

|---|---|---|

| 3mm | Micro motors, sensors, robotics | Tightest fit |

| 4mm | Fans, lab tools, small devices | Balanced fit |

| 6mm | Pumps, larger motors, instruments | Strongest fit |

You should always match the size of your bearings to the needs of your project. A good fit means less vibration, less noise, and longer life for your equipment.

Measuring and Matching Dimensions

You need to measure your space carefully before you choose your bearings. Use a caliper or a micrometer to get the exact inner diameter, outer diameter, and width. These tools help you find the best fit for your shaft and housing.

Follow these steps to measure and match your bearings:

- Measure the shaft diameter: Place the caliper on the shaft where the bearing will sit. Write down the number. This is your inner diameter.

- Measure the housing bore: Use the caliper to check the hole where the bearing will go. This is your outer diameter.

- Measure the width: Check the space between the two sides where the bearing will fit. This is your width.

Note: Always measure twice to make sure you get the right numbers. A small mistake can lead to a poor fit and early failure.

Once you have your measurements, look at the bearing size chart from TFL Bearings. Match your numbers to the closest standard size. If your measurements do not match a standard size, you may need a custom solution. The right fit keeps your bearings stable and reduces wear.

You should also check the tolerance of your bearings. Tolerance tells you how much the size can change during use. A tight tolerance gives you a better fit and smoother operation. Always choose bearings with the right tolerance for your project.

A good fit means your bearings will not move or slip during use. This helps your equipment run quietly and last longer. If you feel unsure, ask an expert at TFL Bearings for help. They can guide you to the best fit for your needs.

Remember: The right size and fit are key to getting the best performance from your bearings. Careful measuring and matching help you avoid problems and keep your project running smoothly.

Application and Installation Tips

Environmental Considerations

You need to match the features of your bearings to the environment of your applications. Each environment brings different challenges. Dust, moisture, and chemicals can affect how your bearings work. You should always check the temperature and humidity in your workspace. Some applications need bearings that resist corrosion. Other applications need bearings that handle high temperatures. If you use bearings in clean rooms or medical applications, you must choose bearings that meet strict standards.

You should also think about vibration and shock. Some applications create strong vibrations. These can damage your bearings if you do not select the right fit. Always review the mounting and installation considerations for your applications. This helps you avoid problems later. When you plan your bearing installation, look at the space and the type of load. A good fit keeps your bearings stable and extends their life.

Tip: For outdoor applications, pick bearings with seals to keep out dirt and water.

Proper Handling and Care

You must handle your bearings with care during installation. Clean hands and tools prevent dirt from entering your bearings. Even small particles can cause problems in sensitive applications. Always store your bearings in a dry, clean place before installation. Do not drop or hit your bearings. This can change the fit and damage the surface.

Follow these steps for bearing installation:

- Check the fit of the bearing and the shaft.

- Use the right tools for installation.

- Apply even pressure to avoid bending the bearing.

- Make sure the bearing sits flat in its place.

Routine maintenance helps your bearings last longer. You should check your bearings for noise, heat, and vibration. Clean and lubricate your bearings as needed. In many applications, regular checks prevent early failure. Good care means your bearings work better in all applications.

Remember: Careful bearing installation and regular checks keep your applications running smoothly.

You need to choose the right miniature ball bearings for your project. Start by checking the load and speed. Make sure the bearings you select can handle your applications. Measure the space to find the best fit. Use the correct size so the bearings work well. Think about the environment and pick bearings that match your needs. Clean and install the bearings with care. The right fit helps your bearings last longer. For expert advice, contact TFL. Explore the full range of miniature ball bearings at TFL Bearings for your next applications.

FAQ

What is a miniature ball bearing?

A miniature ball bearing is a small mechanical part. You use it to reduce friction between moving parts. It helps your machines run smoothly and last longer.

How do I know which bearing size to choose?

You measure the shaft and housing with a caliper. Check the inner diameter, outer diameter, and width. Pick the size that matches your equipment for the best fit.

Can I use bearings in wet or dusty environments?

Yes, you can use bearings in these environments. Choose sealed or stainless steel types. These options protect against water and dust, keeping your equipment safe.

How often should I lubricate my bearings?

You should check your bearings regularly. Lubricate them based on your equipment’s speed and environment. Clean and reapply lubricant to keep everything running well.

Where can I get expert help for my bearing selection?

You can contact TFL Bearings for expert advice. Their team helps you choose the right bearings for your project and offers support for installation and care.