You need to pick angular contact bearings that fit the load, speed, and precision your machine needs. When you choose the right angular contact ball bearings, your machine works better and lasts longer. Studies show that picking the right bearing, with the correct preload and clearance, helps your machine cut more accurately and last longer. If you pick the wrong bearing, your machine may not work well, lose accuracy, and stop working, which can cost a lot. You should think about all the things your machine needs to work well and stay reliable. The right angular contact ball bearings help your machine work better and last longer.

Key Takeaways

- Pick angular contact bearings that fit your machine’s load size, direction, and speed. This helps your machine work better and last longer.

- Double-row bearings can hold more weight and are stiffer. They are good for strong CNC machines that do not have much space.

- Choose the best contact angle and preload for your needs. This helps balance speed, how much weight it can hold, and how accurate it is. Your machine will run smoothly and work well.

- Use high-precision bearings and the right oil or grease. This lowers friction, heat, and wear. Your machine can go faster and last longer.

- Put in and line up bearings with care. Use the right tools and keep things clean. This stops early wear, noise, and loss of accuracy.

Bearing Selection Basics

Load Direction and Size

When picking a bearing for a 5-axis CNC machine, you need to check the load’s direction and size. The load can push sideways, straight, or both ways at once. Each kind of load changes how the bearing works. You must pick a bearing that matches your machine’s load so it can handle the forces when running.

- The load’s size tells you what dynamic and static load ratings you need. If your machine gets bigger loads, you need a bearing with a higher load rating and maybe a bigger size.

- The contact angle is important. A bigger contact angle helps with more straight-line loads. This matters because CNC machines often get mixed loads.

- You can pick single-row or double-row bearings. Double-row bearings can take bigger and two-way straight-line loads. They also make your machine stiffer.

- The bearing’s size should fit the load, speed, and space you have. If the bearing is too big, it can slow the machine down because of more friction.

- The static load rating (C₀) checks if the bearing can hold loads when not moving. The dynamic load rating (C) checks if the bearing works well when running.

- How you put in and pair bearings changes how the load spreads and how long the bearing lasts.

You should always look at your machine’s load needs before picking a bearing. This helps stop too much load and early breakage.

Installation Space

You also need to think about the space for putting in the bearing. In 5-axis CNC machines, the spindle area is often small. This means you need a bearing that fits tight but still works well.

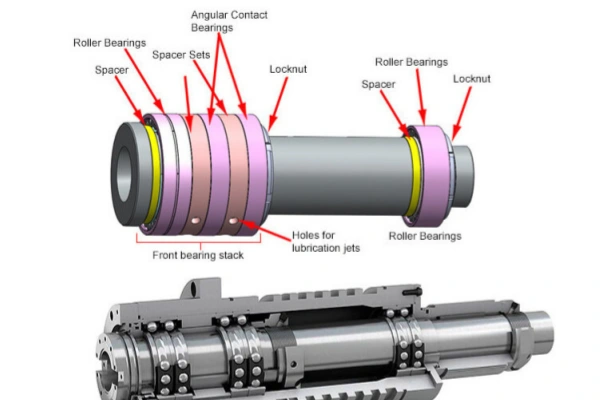

Small bearing designs, like double-row angular contact bearings, save space and keep high load strength and stiffness. These bearings work well in tight spots, like gearboxes and machine tool spindles. The design lets the bearing take both sideways and straight loads, which is needed in small spaces.

When you put a bearing in a small space, you must keep things clean and use the right tools. A press fit on the shaft and a slip fit in the housing help hold the bearing in place. You should use special lock nuts to keep the preload steady and help move the load. These steps make sure the bearing is put in right and lasts longer.

Tip: Always check if the spindle housing is round and straight before putting in the bearing. Clean and lightly grease both the spindle and housing to stop stress and bending.

Small spaces often mean you need a small, high-precision bearing with the right preload and contact angle. This helps balance load strength, stiffness, and how long your CNC machine lasts.

Angular Contact Bearings Types

Single Row vs. Double Row

There are two main types of angular contact ball bearings for CNC machines. These are single-row and double-row angular contact ball bearings. Each type is made for a different job. The table below shows how they are not the same:

| Feature | Single Row Angular Contact Bearings | Double Row Angular Contact Bearings |

|---|---|---|

| Design | One row of balls; simple construction | Two rows of balls; more contact area and stability |

| Load Capacity | Lower axial and radial load; for lighter loads | Higher axial and radial load; for heavy loads, including CNC machines |

| Operating Speed | Higher speeds possible | Slightly lower speed, but less friction and heat |

| Application Suitability | Used in motors, pumps, lighter load applications | Preferred in CNC machines and heavy machinery |

| Special Notes | Limited axial load; best for tight spaces | Handles both radial and axial loads; high static load ratings |

Single-row angular contact ball bearings are good for high speed and small spaces. Double-row angular contact ball bearings are better for CNC machines. They make the machine stronger and can hold bigger loads. These bearings also last longer when the work is hard.

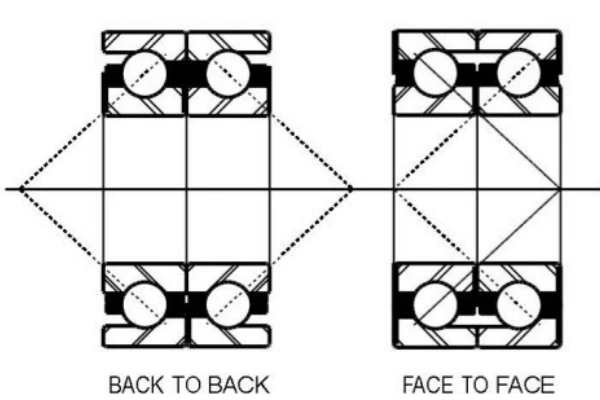

Paired Sets and Arrangements

Many 5-axis CNC machines need more than one angular contact ball bearing. You can use paired sets to keep the ball screw in place. This stops the ball screw from moving the wrong way. Paired angular contact ball bearings can be set up face-to-face or back-to-back. The face-to-face setup is good for CNC machines. It helps if the parts are not lined up just right. This setup keeps the ball screw steady and stops backlash. It also helps the machine move smoothly. You should use paired angular contact ball bearings when you need high precision and no backlash. They also give strong support to the ball screw.

Crossed Roller Alternatives

Some CNC machines need even more strength and accuracy. Crossed roller bearings are good for these jobs. These bearings have rollers that cross each other. This makes them very stiff and accurate. Crossed roller bearings can hold both radial and axial loads at once. Their small size fits well in tight spaces. You should use crossed roller bearings when you need the most precision and strength. They are great for advanced CNC machines or when space is very small. Most people use angular contact ball bearings, but crossed roller bearings work better for special jobs.

Tip: Sealed angular contact ball bearings keep out dust and hold in grease. This helps your bearings last longer in tough CNC jobs.

Key Performance Factors

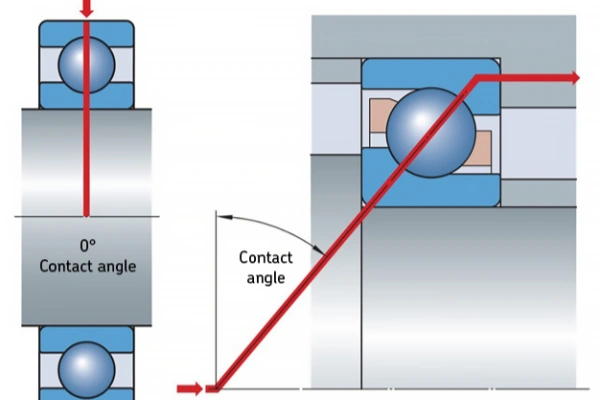

Contact Angle Selection

When you pick an angular contact ball bearing, you should check the contact angle. The contact angle is the space between where the ball touches the raceways and a line that goes straight up from the bearing’s center. This angle helps decide how much force the bearing can take from the side. Most angular contact ball bearings have contact angles of 15°, 25°, or 40°.

If the contact angle is bigger, the bearing can hold more force from the side. A smaller contact angle is better if you want the bearing to spin fast and don’t need it to hold much side force. The table below shows how the contact angle changes what the bearing can do and where you might use it:

| Contact Angle (°) | Axial Load Capacity | Typical Application |

|---|---|---|

| 15 | Lower axial load capacity | High-speed applications with small axial loads |

| 25 | Medium axial load capacity | Applications needing moderate axial load capacity |

| 40 | Higher axial load capacity | Applications needing high axial load capacity |

A 15° contact angle is good for spindles that need to go fast. If your machine needs to handle more force from the side, you should pick a 25° or 40° contact angle. When the contact angle gets bigger, the bearing can’t handle as much force from above, but it can take more from the side. You need to balance these things so your CNC machine works well and stays efficient.

Precision Grade

Precision is very important for fast or super-precise angular contact ball bearings. You will see grades like ABEC-5, ABEC-7, and ABEC-9. These match ISO classes P5, P4, and P2. Higher numbers mean the bearing is made more carefully and is more accurate. The table below shows how the grades compare and where you might use them:

| Precision Grade | Corresponding ISO Class | Typical Applications |

|---|---|---|

| ABEC-5 | ISO P5 | High precision uses such as machine tools and robotics |

| ABEC-7 | ISO P4 | Super precision applications including aerospace and medical |

| ABEC-9 | ISO P2 | Ultra precision uses like optical instruments and high-speed spindles |

CNC spindles need high precision grades like ABEC-7 or ABEC-9. These bearings help your machine cut better and make less noise. They also help your tools last longer. High precision makes your machine work better at fast speeds and keeps it steady. If you use the right grade, your bearing will work well and last longer in every job.

Material and Thermal Resistance

The material of your angular contact ball bearing changes how it works and how long it lasts. Most bearings are made of steel, but some use ceramic balls. Ceramic balls are used in super-precision angular contact ball bearings for fast CNC spindles. The table below compares steel and ceramic bearings:

| Performance Aspect | Steel Bearings | Ceramic Bearings (Silicon Nitride) |

|---|---|---|

| Density | 100% (baseline) | ~40% of steel (lighter mass) |

| Thermal Expansion | 100% (baseline) | ~29% of steel (smaller expansion) |

| Modulus of Elasticity | 100% (baseline) | ~151% of steel (higher stiffness) |

| Hardness (HV10 at 20°C) | ~700 | ~1700 (greater hardness) |

| Centrifugal Load at 15,000 rpm | 174 N (for 12.7 mm ball diameter) | 71 N (same size ball), 32 N (smaller ceramic ball) |

| Dynamic Load Rating | 100% (baseline) | ~70% of steel (lower rating but offset by other factors) |

| Stiffness at 40,000 rpm | Reduced to 61% of static stiffness | Reduced to 70% of static stiffness (better retention) |

| Temperature Sensitivity | Higher preload increase due to thermal expansion | Less sensitive; preload increase smaller or may decrease |

| Service Life | Baseline | Longer service life under grease lubrication |

Ceramic balls are lighter, harder, and stiffer than steel balls. This means they make less friction and heat. They also last longer. Ceramic bearings keep their tightness better when things get hot. This helps your machine stay accurate, even when it runs fast. If you want the best results, pick super-precision angular contact ball bearings with ceramic balls for your spindle.

It is also important that the bearing can handle heat. If the bearing gets too hot and cannot take it, it will change shape and get weaker. This can make your machine shake and not cut as well. Good thermal resistance keeps your machine working right, even when it runs fast for a long time. Always pick a bearing material that matches your machine’s speed, force, and heat needs.

Lubrication Needs

Lubrication is very important for angular contact ball bearings. It helps stop friction, keeps the bearing cool, and stops it from wearing out. You can use grease or oil. Each one is good for different jobs. Grease-packed bearings do not need much care and work well in slow, closed places. Oil-air lubrication is best for fast, moving spindles because it cools the bearing and keeps dirt away.

| Lubrication System Type | Description | Advantages | Disadvantages |

|---|---|---|---|

| Permanent Grease-Packed Bearings | Bearings sealed with grease for life, no grease replacement possible. | Low maintenance, contaminant-free, cost-effective, proven technology. | Limited to slower speeds, grease cannot be replaced or refreshed. |

| Oil-Air Bearing Lubrication | Uses oil mixed with air (oil mist or oil injection) delivered continuously to bearings. | Supports higher speeds, extends bearing life, actively cools and clears contamination. | Higher initial cost, requires monitoring and maintenance of oil delivery system. |

For fast angular contact ball bearings, synthetic grease or special lithium grease works well. These greases can take heat, water, and do not break down easily. They help the bearing run smoothly and stop rust. Oil mist or oil injection is best for super-precision angular contact ball bearings in fast CNC spindles. You must keep all oil lines clean so dirt does not get in.

Tip: Sealed angular contact ball bearings keep grease inside and dirt outside. This means you do not have to fix them as much and they last longer.

If you use the wrong lubricant or not enough, the bearing will get hot and wear out faster. This can make the bearing break early. Always use the right thickness of lubricant for your bearing’s speed and heat. If your machine runs fast or carries heavy loads, you should add new lubricant often. Good lubrication and sealing help your bearing work better and last longer in every job.

Matching Bearings to Application

Speed and Rigidity

You have to pick the right angular contact ball bearings for your machine’s speed and how stiff it needs to be. In 5-axis CNC machines, spindle speed and stiffness are very important. They help your machine cut well and last longer. Angular contact ball bearings work well for high-speed jobs. They can handle both side and straight forces with great accuracy. These bearings often spin faster than 20,000 RPM. That is much faster than other bearing types.

| Bearing Type | Typical Maximum Spindle Speed (RPM) | Key Characteristics |

|---|---|---|

| Angular Contact Ball Bearings (ACBB) | Often exceed 20,000 RPM | High rigidity, reduced friction, compact size, suitable for high-speed precision spindles |

| Tapered Roller Bearings | Up to 7,000 RPM | Supports heavy radial and axial loads, used in high torque applications |

| Needle Bearings | Up to 10,000 RPM | Compact, sturdy, used in high-speed moving parts like tool changers and feed mechanisms |

Ultra-high speed bearings are best for fast spindles. They keep your spindle steady and accurate, even when spinning fast. High rigidity in angular contact ball bearings helps stop shaking. Less shaking means smoother surfaces and better accuracy. Rigid bearings also protect your tools and machine parts from wearing out too soon.

Shaking can make your machine work badly. It can make rough surfaces and mistakes in your parts. Angular contact ball bearings with high rigidity help stop these problems. You get better stability, so your machine stays steady at high speeds. This is important for good results and accuracy every time.

Preload Options

Preload is the force that keeps the bearing parts tight together. You need to pick the right preload for your job. Preload takes away gaps inside the bearing. This makes the bearing stiffer and more exact. If you use too little preload, the bearing will shake and make noise. If you use too much, it will get hot and wear out faster.

Here are the main preload choices for angular contact ball bearings in CNC spindles:

- Light Preload:

Use this for very fast jobs. It lowers friction and noise. Your machine runs smoother and quicker. - Medium Preload:

This is good for medium loads. It balances speed and strength. It keeps the bearing stiff enough. - Heavy Preload:

Pick this for the most stiffness. It is best for heavy loads but can slow down your spindle.

There are also different ways to set preload:

- Rigid preload (solid preload):

You use spacers or threads to lock the preload in place. This gives the most stiffness. It works best in shops where the temperature does not change much. - Spring preload:

You use springs to keep the pressure steady, even if it gets hotter or colder. This helps in fast jobs. - Hydraulic preload:

You use oil pressure to change the preload while the spindle runs. You can use less preload at high speeds and more when cutting.

Note: Preload changes the bearing’s temperature. Too much preload makes it hot and can make it wear out faster. Too little preload lets it shake and wear out. Always check the temperature when running fast.

Preload also changes how your machine sounds and feels. The right preload makes your machine quieter and more exact. Duplex bearings with built-in preload, like back-to-back or tandem sets, give more stiffness and less shaking. These setups help you get the best from your ultra-high speed bearings.

Mounting and Alignment

You must mount and line up your angular contact ball bearings carefully. Good mounting spreads the load evenly and helps the bearing last longer. If you do not line up the bearing right, it can wear unevenly, shake more, and lose accuracy. This can make the bearing fail early and hurt other machine parts.

| Aspect | Effect of Improper Mounting or Misalignment on Angular Contact Bearings in CNC Machines |

|---|---|

| Difficulty in Mounting | If not lined up, bearings are hard to install; forcing them can damage the rollers or raceways, making them wear out before you even use them. |

| Incorrect Pre-loading | Bad alignment messes up preload, so some rollers get too much force and wear out fast, while others get too little and cause shaking. |

| Increased Friction & Heat | Rollers slide instead of rolling, which makes more friction and heat, breaks down the lubricant, and causes more wear. |

| Uneven Load Distribution | Some rollers get too much force and can crack or break, lowering how much the bearing can hold and risking sudden failure. |

| Reduced Rotational Accuracy | Bad alignment makes the bearing spin unevenly, causing shaking, noise, and mistakes in CNC work. |

| Overall Consequence | All these problems together can make the bearing fail early and damage other machine parts, making your CNC machine less reliable and less accurate. |

Always use the right tools and steps when putting in angular contact ball bearings. Keep your work area clean and handle the bearings gently. Check the alignment before you finish. If you hear noise, feel shaking, or notice heat, check the bearing right away.

Tip: Check your bearings often and use good lubricant to help them last longer. Work with trusted suppliers for help with installation and preload.

Good mounting and alignment help your bearings work their best. You keep your machine working well and accurately every time. Ultra-high speed bearings need extra care when you put them in and set preload so they can work their best in fast jobs.

When you pick angular contact ball bearings for your 5-axis CNC machine, you must make sure the bearing fits your job. First, look at how much weight your machine will carry, how fast it will go, and how exact it needs to be. Choose the best contact angle and preload to help your machine work better. Use high-precision bearings and put them in the right way to keep your machine working well and making accurate parts.

If you want help, TFL Bearings can give you advice. Our team can help you find the best angular contact ball bearings for your needs. We will help you get the right bearing so your machine works well and lasts a long time.

FAQ

What is an angular contact bearing?

An angular contact bearing is a type of ball bearing. It supports both side (axial) and up-and-down (radial) loads. You often use it in machines that need high speed and accuracy, like 5-axis CNC machines.

What does the contact angle mean in a bearing?

The contact angle shows how the bearing handles force. A bigger angle lets the bearing take more side force. You pick the angle based on your machine’s speed and load needs.

What happens if you use the wrong preload?

If you use too much preload, the bearing gets hot and wears out fast. Too little preload lets the bearing shake and lose accuracy. You must choose the right preload for your machine.

What is the difference between single-row and double-row angular contact bearings?

| Type | What It Does |

|---|---|

| Single-row | Handles lighter loads and higher speed |

| Double-row | Handles heavier loads and more force |

You pick the type based on your machine’s load and space.