Insulation coating technologies for bearings are now very important. This is because machines face more electrical damage today. More than 40% of motor failures happen because of bearing problems. Electrical erosion is becoming a bigger problem. Insulation coating materials like advanced ceramics and composites are popular now. They help stop bearing currents and make machines work better. The global market for these coatings was almost USD 780 million in 2024. People want more energy efficiency and better protection from electrical failure. Ceramic coatings give the best insulation. But not all materials or coatings work the same way.

Key Takeaways

- Insulation coatings on bearings keep bad electricity away. This stops damage and helps machines last longer. Machines also work better with these coatings.

- Ceramic materials like alumina block electricity very well. They also protect from heat. Polymers and composites make the coating bend and last longer.

- There are different ways to put on coatings. Plasma spraying and vapor deposition are two ways. These change how thick, strong, and costly the coating is.

- Insulated bearings stop stray currents that hurt bearings. This keeps away pitting and wear. It also makes machines quieter and stops them from breaking. The bearing size does not change.

- Picking the right bearing material and coating is important. It depends on how hot, heavy, or electric the machine is. This helps the bearing last and keeps it safe.

Insulation Coating Materials Overview

Ceramic Materials

Ceramic materials are very important for insulation coating materials for bearings. These materials stop electricity from passing through. They also handle heat and do not rust easily. Alumina (Al2O3) is the most used ceramic for insulation coatings. It keeps its properties even when it gets hot or worn down. Mullite and spinel are also used, but alumina is picked most because it works well and does not cost too much.

| Ceramic Material | Usage in Bearings Insulation Coatings | Electrical Properties / Notes |

|---|---|---|

| Alumina (Al2O3) | Widely used, applied by thermal spraying | High electrical resistance; commonly used |

| Mullite (3Al2O3·2SiO2) | Used for thermally sprayed insulation coatings | Slightly higher impedance than alumina |

| Spinel | Promising oxide ceramic for insulation | Less common than alumina and mullite |

| Yttria (Y2O3) | Used in composites for improved insulation | High resistance and thermal stability |

Alumina coatings can block electricity up to 10^12 ohms at room temperature. This helps protect the bearing from stray electricity. Ceramic coatings also stop wear and rust. This makes them good for places with lots of heat or chemicals.

Polymer and Composite Materials

Polymer and composite bearing materials are now popular for insulation coating materials. PTFE, polyimide, and Vespel® are top choices. PTFE, also called Teflon®, is slippery and handles heat well. Polyimide is strong in heat, keeps its shape, and does not get damaged by chemicals. Vespel® mixes polyimide with things like graphite or PTFE to make it last longer and slide better.

| Material | Key Properties Relevant to Insulation Coatings in Bearings | Supporting Applications and Notes |

|---|---|---|

| Vespel® Polyimide | Exceptional wear resistance, low friction, dimensional stability, chemical resistance, low outgassing, maintains mechanical properties over wide temperature range (cryogenic to elevated temps) | Used in aerospace, semiconductor, vacuum, and scientific instrumentation bearings; grades with fillers (graphite, PTFE, MoS2) enhance wear resistance and friction reduction |

PTFE (Teflon®) | Low coefficient of friction, contributes to wear resistance when combined with polyimide composites (e.g., Vespel® SP-211) | Incorporated as filler in Vespel® SP-211 to achieve lowest friction and excellent wear resistance up to 300°F |

| Polyimide | High temperature resistance, creep resistance, low thermal expansion, chemical resistance, dimensional stability | Ideal for demanding bearing applications requiring thermal and mechanical stability |

Composite bearing materials mix ceramics, polymers, and sometimes metal fibers. This makes them tough and long-lasting. These materials are stiff and hard like ceramics. They are also flexible and can fix small damage like polymers. Composites can keep out rust even if they get scratched. Pure ceramics cannot do this. That is why composites are used when both strength and protection are needed.

| Material Type | Advantages | Disadvantages |

|---|---|---|

| Pure Ceramics | Excellent corrosion and wear resistance, high stiffness, thermal stability, heat resistance | Brittle, low fracture toughness, low tensile strength, susceptible to fracture |

| Composite Materials | Improved mechanical strength, fracture toughness, fatigue resistance, combine unique properties | Complex manufacturing, interface issues, performance depends on phase integration |

| Polymers | Flexibility, self-healing, corrosion protection, easy application, heat resistance | Lower mechanical strength, less suitable for high-load or high-heat applications |

Tip: Composite bearing materials can give the best parts of ceramics and polymers. They resist heat and rust but are not as easy to break.

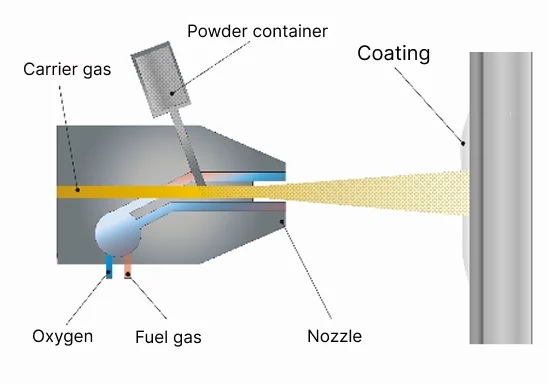

Application Methods

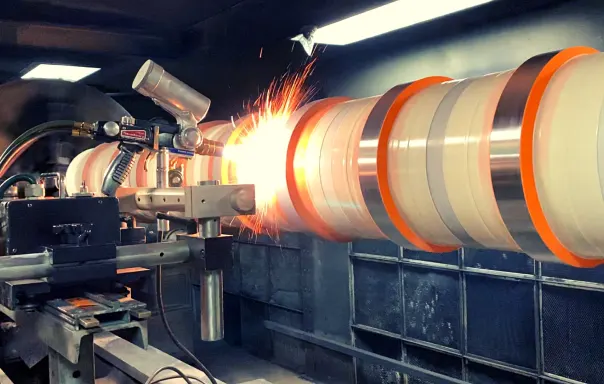

Manufacturers use different ways to put insulation coating materials on bearings. The way they do it changes how thick, strong, and costly the coating is. Plasma spraying and thermal spraying are the main ways for ceramic coatings. These methods let people control how thick the coating is. They also make the coating stick well to the bearing. Plasma spraying can put alumina coatings as thin as 50 to 120 micrometers. This is enough to stop electricity without making the bearing bigger.

| Coating Method | Typical Thickness Range | Notes |

|---|---|---|

| Arc and Flame Thermal Spray (metallic alloys) | Up to ~0.25 inches (6.35 mm) | Suitable for thicker coatings, dimensional restoration |

| HVOF or Plasma Spraying (cermets, carbides, ceramics) | Up to 0.020 inches (0.51 mm) | Typical for ceramics and cermets |

| HVAF Thermal Spray | Up to 0.050 inches (1.27 mm) or more | Exceptionally thicker coatings possible |

Spray coating is often used for polymer coatings. It is cheap and simple to use. Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD) are special ways to make thin, hard coatings. These coatings last a long time and handle heat well. These methods cost more but work best for tough jobs.

| Application Method | Typical Coating Materials | Cost Considerations | Effectiveness / Advantages |

|---|---|---|---|

| Physical Vapor Deposition (PVD) | Metallic, Ceramic coatings | More costly, advanced technology | Produces hard, wear-resistant coatings; suitable for thin films |

| Chemical Vapor Deposition (CVD) | Diamond-Like Carbon (DLC) coatings | Likely higher cost, complex process | Excellent hardness, wear resistance, and low friction |

| Electroplating | Metallic coatings (e.g., Chromium) | Moderate cost | Good hardness and corrosion resistance |

| Spray Coating | Polymer coatings (e.g., PTFE, Polyimide) | Generally economical and user-friendly | Provides low friction, good wear resistance, easier application |

Plasma spraying is great for putting on strong alumina coatings, like those in INSOCOAT bearings. These coatings can handle up to 3,000 V DC and still work well in heat and wear. Dipping and electrochemical deposition are also used for some polymer and composite coatings. These ways help cover the whole bearing evenly.

Note: The way you put on the coating depends on the bearing material, how thick you want the coating, the cost, and what you need for wear, heat, and rust protection.

How Insulated Bearings Work

Electrical Insulation Function

Insulated bearings have a special layer that stops electricity. This layer is made from ceramic or polymer. It covers the bearing rings or sometimes the rolling parts. The insulation has very high resistance to electricity. This high resistance blocks stray currents during machine use.

| Aspect | Explanation |

|---|---|

| Insulation Material | Ceramic or special polymer coatings are put on as thin layers. These go on bearing rings and sometimes rolling parts. They have high resistance and block stray currents. |

| Mechanism | The coating acts like a wall that stops electricity. It keeps current from moving through the bearing parts. This stops current from passing through raceways and rolling parts. |

| Electrical Protection | Insulation can block thousands of volts DC. This stops damage like pitting, fluting, and oil breakdown from electrical currents. |

| Durability | Coatings keep working even with heat and moisture. They give good protection without changing the machine. |

| Bearing Types | There are coated insulated bearings with ceramic or polymer layers. Hybrid bearings use ceramic rolling parts for better insulation and strength. |

| Benefits | These bearings lower electrical damage and last longer. They need less fixing and help machines work better, especially in motors with variable frequency drives. |

| Comparison to Standard Bearings | Insulated bearings have much higher resistance, often over 200 MΩ. They fight electrical damage better and last longer without changing the machine design. |

The insulation layer works like a shield. It stops electricity from moving between the shaft and the housing. This is important in motors with variable frequency drives. These drives can make stray currents that hurt the bearing. Using a high-resistance material, the bearing can block up to 3,000 volts DC. The insulation keeps working even with heat, water, or chemicals. This means the bearing works well in tough places and still protects.

Current-insulated bearings use these coatings to keep the bearing apart from the rest of the machine. The insulation does not change the size or shape of the bearing. This makes it easy to swap out old bearings. The insulation, like aluminum oxide or special polymers, helps the bearing handle both electric and mechanical stress.

Protection Against Damage

Insulated bearings protect against many kinds of electrical damage. If electricity goes through a normal bearing, it can cause pitting, fluting, scoring, and grooves. These problems happen because of electrical sparks inside the bearing.

- Pitting: Small holes or craters form on the bearing.

- Fluting: Wavy grooves show up from repeated sparks.

- Scoring: Scratches or lines appear on the raceways.

- Grooves: Deep channels form, causing more wear and noise.

These damages often happen in motors with bad grounding or variable frequency drives. The insulation layer blocks the path for electricity. This stops sparks and keeps the bearing surface smooth.

Insulated bearings also lower noise, vibration, and sudden failures. By stopping electrical damage, they help the bearing last longer and make machines more reliable. The insulation acts like a shield, even during cold starts or low oil pressure. Experts say coated bearings last longer and wear out less in tough jobs. The coating’s anti-friction layer protects the bearing when oil is missing. This means less damage at engine start and fewer costly fixes.

Current-insulating coatings on bearing rings keep the bearing safe from electricity. These coatings can handle up to 3,000 volts. They let the bearing keep the same fit as regular bearings. This makes them easy to use as replacements. By stopping electrical damage, insulation coatings lower bearing failure. Machines with insulated bearings last longer and break down less.

Tip: Insulated bearings are great for big motors and machines with variable frequency drives. They help stop early failure and keep machines running well.

Bearing Material Selection

Choosing the Right Material

Picking the best bearing material is very important. It helps the bearing work well and last longer. Engineers look at how each material handles heat, rust, wear, and shocks. Ceramic materials like silicon nitride, zirconia, and alumina block electricity and handle heat well. These materials also fight rust and wear, so they work in tough places. Composite bearing materials mix ceramics and polymers. This makes them better at handling shocks and staying strong. Polymer-based bearing materials, such as polyimide and PTFE, cost less and stop rust. But they do not handle heat or wear as well as ceramics.

| Criteria | Ceramic Materials (e.g., silicon nitride, zirconia, alumina) | Resin Materials (e.g., epoxy, polyimide) |

|---|---|---|

| Electrical Insulation | Excellent, extreme resistance to electrical breakdown | Good, can be enhanced with additives |

| Temperature Stability | High, suitable for high-temperature environments | Moderate, less stable at high temperatures |

| Hardness and Strength | High hardness and fracture toughness | Lower hardness, less durable under heavy loads |

| Corrosion Resistance | High, especially ceramics like alumina | Moderate, depends on resin formulation |

| Cost | Higher due to material and processing complexity | Lower, more cost-effective |

| Service Life and Maintenance | Longer service life, lower maintenance costs | Shorter service life, potentially higher maintenance |

Composite bearing materials give a good mix of price, strength, and how well they work. Engineers need to think about the size and type of bearing. They also look at how much weight it will hold, how fast it spins, and if there is electricity nearby. The right material lets the bearing handle heat, rust, and wear. It also helps the bearing take shocks and stay strong.

Application Considerations

The way the bearing is used matters a lot when picking the material. Electric motors with variable frequency drives make high-frequency currents. These currents can hurt bearings if they are not insulated. Ceramic hybrid bearings use ceramic balls that do not let electricity pass. This keeps the bearing safe and lowers wear. These bearings also make less friction and heat, so they last longer. Composite bearing materials are picked because they handle shocks, heat, and rust.

Things like temperature, wetness, and chemicals can change how well the bearing works. High heat can break down insulation. Cold can make materials crack. If the place is full of chemicals, you need bearings that do not rust, like stainless steel or composites with PTFE or epoxy coatings. Good seals and real-life tests help make sure the bearing stays strong and works well.

- Think about voltage, frequency, bearing size, weight, speed, heat, and price.

- Make sure insulation can handle the voltages it will face.

- Pick a bearing material that can take heat, rust, wear, and shocks.

- Use composite bearing materials if you need both strength and flexibility.

- Test the bearing and its coating in fake real-world settings to check how well it works.

Tip: Always check insulation resistance after putting in the bearing. This helps make sure there are no short circuits. Handle and install bearings carefully to keep the material and coatings safe.

Benefits of Insulated Bearings

Electrical Damage Prevention

Insulated bearings help keep machines safe from electrical damage. Motors with variable frequency drives can make stray currents. These currents sometimes go through the bearing and cause sparks. Sparks can wear away the bearing surface and make it fail early. Insulation coatings on the bearing act like a wall. They stop the current from moving through the bearing. This keeps the bearing safe from pitting, fluting, and other damage.

- Shaft currents can move through the bearing in some motors.

- Sparks from these currents hurt the bearing and make it wear out faster.

- Big motors often have insulation on one end of the bearing.

- Small motors may need both bearings insulated or extra grounding.

- Insulation coatings stop current and help bearings last longer.

A thin ceramic or polymer layer gives this electrical insulation. Polyimide-based coatings, like Vespel, can handle heat and last a long time. These coatings also help protect against high-frequency voltage spikes. But ceramic coatings can break easily, and some polymer coatings may wear out if not picked right. Using shaft grounding rings with bearing insulation gives even more protection.

Note: Insulated bearings do not protect other parts of the machine. If not managed, currents can still go through other paths.

Extended Service Life

Insulated bearings help machines last longer. The insulation layer protects the bearing from both electrical and physical damage. This means the bearing can work longer, even in places with heat, water, or chemicals. Picking the right bearing material, like ceramic or composite, makes it even stronger. These materials fight heat and wear, so the bearing is more dependable.

| Benefit | Description |

|---|---|

| Longer Bearing Life | Insulation stops electrical damage, so bearings last longer. |

| Less Maintenance | Machines need fewer fixes and new parts. |

| Better Durability | The bearing fights heat, wear, and rust. |

| Stable Performance | The bearing keeps working well, even with heat or heavy loads. |

The right bearing material helps the bearing take shocks and spin fast. Polyimide-based insulation is strong and handles heat well. This makes it a good pick for tough jobs. Insulated bearings help companies save money by lowering repair costs and downtime. They also help machines run smoothly for a longer time.

Tip: Always pick a bearing material that fits the machine’s needs for heat, strength, and electrical safety.

Insulation coating technologies have made bearings work better in today’s machines. Studies show some important things:

- Aluminum oxide coatings put on by plasma spraying help stop electrical damage in motors and generators.

- New graphene coatings make bearings last longer and block electricity better.

- Coated bearings need less fixing and help machines run longer, which saves money.

- Different ways to coat bearings work best for certain jobs, like PVD for fast-moving or dry bearings.

Experts say you should pick the right coating for each job:

| Coating Type | Key Properties | Recommended Applications |

|---|---|---|

| Polymer | Low friction, wear resistance | Engines, compressors, pumps |

| Ceramic | High hardness, heat tolerance | Aerospace, food processing |

| DLC | Low friction, high hardness | Automotive, high-performance |

Choosing the best bearing material and insulation helps machines work well, last longer, and stay safe. If you need help picking the right one, contact us at TFL Bearings for advice.

FAQ

What is the main purpose of insulation coatings on bearings?

Insulation coatings keep electricity from going through the bearing. This helps stop damage like small holes and grooves. Machines with these coatings last longer and break less often.

How do engineers choose the right insulation coating for a bearing?

Engineers check the machine’s voltage, heat, and where it will be used. They pick a coating that fits what the bearing needs. Ceramic and composite coatings are good for high heat and strong electrical safety.

Can insulated bearings replace standard bearings without design changes?

Yes. Insulated bearings are the same size as regular ones. They fit into machines without any changes. This makes it easy and cheap to upgrade.

How should users maintain insulated bearings?

Users should keep bearings clean and dry. They should check for wear or coating damage often. Putting them in the right way also keeps the insulation safe.

Are insulated bearings suitable for all types of machines?

Insulated bearings work best in motors, generators, and pumps. Machines with high voltage or changing power need them most. Some machines with low voltage may not need this kind of protection.