In modern industrial machinery, the demand for higher speeds, greater accuracy, and improved reliability continues to grow. Bearings play a central role in meeting these demands, particularly in applications where both radial and axial loads must be handled simultaneously. Among advanced bearing solutions, angular contact ball bearings stand out for their ability to deliver high precision, excellent stiffness, and stable performance at elevated speeds.

Angular contact ball bearings are widely used in machine tools, electric motors, automotive systems, and precision equipment, where standard ball bearings are insufficient. This article explains how angular contact ball bearings work, their key features and benefits, and where they perform best across different industries.

What Are Angular Contact Ball Bearings

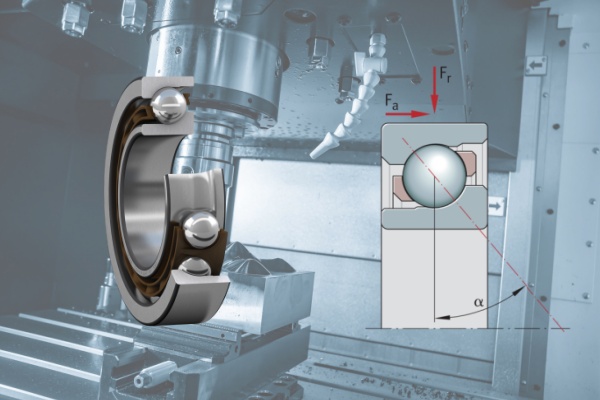

Angular contact ball bearings are rolling bearings designed so that the contact angle between the balls and raceways allows them to support combined radial and axial loads. Unlike deep-groove ball bearings, which primarily handle radial loads, angular contact bearings are optimized for applications where axial forces are significant.

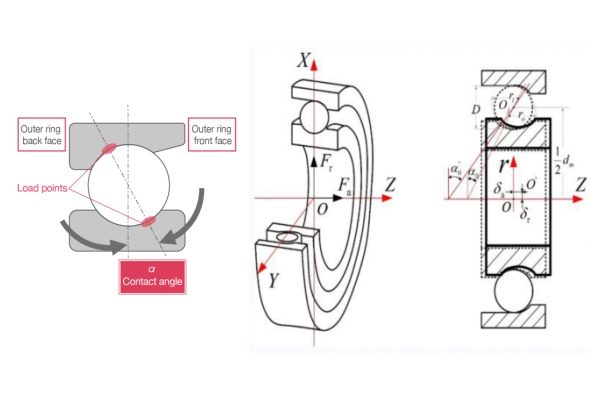

The contact angle is the defining feature of this bearing type. It determines how loads are transmitted through the bearing and directly influences load capacity, speed capability, and stiffness. Because of this design, angular contact ball bearings are essential in applications requiring precise shaft positioning and stable rotational performance.

How Angular Contact Ball Bearings Work

In angular contact ball bearings, the raceways of the inner and outer rings are offset relative to each other along the bearing axis. This offset creates an angle at which the load is transmitted from the balls to the raceways. As a result, the bearing can support axial loads in one direction in addition to radial loads.

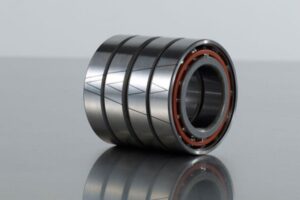

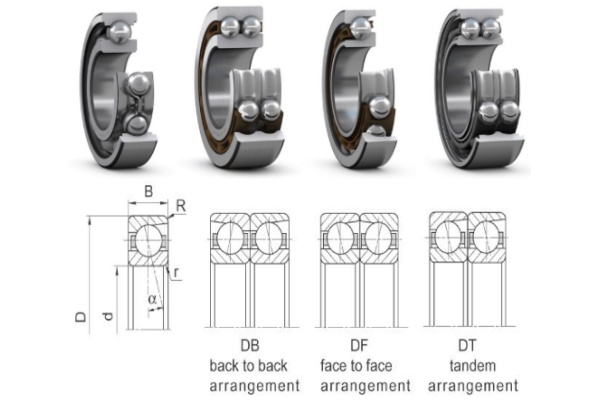

To handle axial loads in both directions, angular contact ball bearings are often mounted in pairs or sets. Common arrangements include back-to-back, face-to-face, and tandem configurations. These arrangements improve load capacity, rigidity, and alignment accuracy, making them ideal for high-precision machinery.

Proper arrangement is key to performance. At SDTFL Bearings, we provide matched sets (DB, DF, DT) pre-adjusted for optimal preload. [Get a quote] for our matched angular contact sets today.

Key Features of Angular Contact Ball Bearings

One of the most important features of angular contact ball bearings is their ability to operate at high speeds while maintaining precise motion control. Their internal geometry minimizes friction and allows smooth rolling even under combined loading conditions.

These bearings also offer high axial stiffness, which is critical in applications where shaft deflection must be minimized. Precision manufacturing ensures tight tolerances, reduced vibration, and consistent performance. Depending on application needs, angular contact ball bearings are available in single-row, double-row, and matched set designs.

Benefits of Using Angular Contact Ball Bearings

The primary benefit of angular contact ball bearings is their capability to handle combined loads efficiently. This makes them superior to standard ball bearings in applications involving axial forces. Their high stiffness improves positional accuracy, which is essential in precision equipment.

Angular contact ball bearings also support high rotational speeds, making them suitable for motors and machine tool spindles. Reduced vibration and improved thermal stability contribute to longer service life and consistent performance. These advantages translate into lower maintenance requirements and enhanced operational efficiency.

Single-Row vs Double-Row Angular Contact Bearings

Single-row angular contact ball bearings are designed to support axial loads in one direction and are typically used in paired arrangements. They are ideal for high-speed and high-precision applications where flexibility in bearing arrangement is required.

Double-row angular contact ball bearings can support axial loads in both directions within a single bearing unit. They provide higher load capacity and rigidity, but are generally larger and less flexible in mounting. The choice between single-row and double-row designs depends on load requirements, space constraints, and design complexity.

Best Applications for Angular Contact Ball Bearings

Angular contact ball bearings are widely used in machine tools, particularly in spindles where accuracy and speed are critical. Their ability to maintain precise shaft alignment under load makes them ideal for milling machines, lathes, and grinding equipment.

In electric motors, angular contact ball bearings support axial forces generated during operation, especially in high-speed and high-power motor designs. They are also commonly used in pumps and compressors where combined loads are present.

Automotive applications include transmissions, gearboxes, and performance-critical rotating assemblies. In these systems, angular contact ball bearings contribute to smooth power transmission and long-term reliability.

Angular Contact Ball Bearings in High-Precision Industries

High-precision industries such as robotics, automation, aerospace, and medical equipment rely heavily on angular contact ball bearings. In robotic joints and automation systems, these bearings provide the stiffness and accuracy required for controlled motion and repeatability.

In aerospace and medical applications, where safety and precision are paramount, angular contact ball bearings ensure stable operation under demanding conditions. Their predictable performance and high manufacturing standards make them suitable for critical systems.

Popular Angular Contact Bearing Series

Selecting the correct series is vital for optimizing machine performance. Below are the most common Angular Contact Ball Bearing series we manufacture at SDTFL, designed to meet international ISO standards:

- 7000 Series (High Precision): Ultra-light series, ideal for high-speed precision spindles where space is limited.

- 7200 Series (Standard & Insulated Options): The industry standard for pumps and motors, balancing size with high load capacity.

- 7300 Series (Heavy Duty): Designed with thicker cross-sections to support heavier combined loads in demanding industrial equipment.

- 3200 / 5200 Series (Double Row): Equivalent to two single-row bearings in a back-to-back arrangement, perfect for gearboxes requiring rigid axial guidance.

- QJ Series (Four-Point Contact): A specialized design capable of handling axial loads in both directions with a split inner ring, often used in compressors.

Note: SDTFL Bearings offers these series in various cage materials (Brass, Polyamide, Steel) and precision classes. [View our full catalog] for detailed dimensional data.

Material Options and Design Considerations

Angular contact ball bearings are commonly manufactured from high-quality bearing steel for strength and fatigue resistance. For specialized applications, stainless steel or hybrid designs using ceramic balls may be used to improve corrosion resistance or reduce friction.

Design considerations include contact angle selection, internal clearance, cage material, and lubrication method. Each factor influences performance characteristics such as speed capability, load capacity, and thermal behavior. Proper selection ensures optimal performance and extended service life.

Role of Angular Contact Ball Bearings in OEM Manufacturing

For OEMs, selecting the right bearing is essential for product performance and reliability. Angular contact ball bearings are often chosen in OEM designs where standard bearings cannot meet load or precision requirements.

Custom configurations, matched bearing sets, and application-specific designs allow OEMs to optimize machinery performance. Working with an experienced bearing manufacturer ensures that angular contact ball bearings are tailored to exact operational needs.

Partnering with the right factory makes all the difference. SDTFL Bearings supports OEMs with private labeling, custom packaging, and just-in-time delivery. [Start your partnership] with us today.

TFL Bearings’ Expertise in Advanced Bearing Solutions

TFL Bearings strongly focuses on delivering high-quality bearing solutions across multiple categories, including ball bearings, roller bearings, thin-section and miniature bearings, electric motor bearings, automotive bearings, and custom OEM manufacturing.

With a strong emphasis on precision engineering and consistent quality, TFL Bearings supplies angular contact ball bearings designed to meet the demands of high-speed, high-accuracy applications. The company’s capability in both standard and customized bearing solutions allows it to support diverse industries and complex engineering requirements.

Through advanced manufacturing processes and strict quality control, TFL Bearings ensures that its angular contact ball bearings deliver reliable performance, long service life, and excellent value for industrial customers worldwide.

Angular contact ball bearings play a vital role in modern machinery by supporting combined loads, enabling high-speed operation, and maintaining precise shaft alignment. Their unique design makes them indispensable in industries where accuracy, reliability, and efficiency are essential.

From machine tools and electric motors to automotive systems and advanced OEM applications, angular contact ball bearings provide performance advantages that standard bearings cannot achieve. With strong expertise in ball bearings, roller bearings, and custom OEM solutions, TFL Bearings continues to support high-precision industries with dependable and engineered bearing solutions.

Partner with SDTFL Bearings for Precision and Reliability

At SDTFL Bearings, we know that selecting the right angular contact ball bearing is critical for the longevity of your machinery. We are more than just a supplier; we are a manufacturing partner dedicated to providing high-quality, factory-direct bearing solutions that fit your budget and technical specifications.

Whether you need a custom OEM order, a specific matched set for a spindle, or a bulk supply of standard series bearings, we have the production capacity and engineering expertise to support your business.

Ready to upgrade your supply chain?

- Request a Fast Quote: Send your requirements directly to info@sdtflbearing.com

- Speak to an Engineer: Call us at +86 15806631151

- Get Instant Access: [Click here to fill out our inquiry form] or hit the “Contact Us” button on the sidebar.

Let’s keep your world moving—reach out to us today!