In high-performance systems, managing loads presents intricate issues. Because they can accommodate axial and radial forces at the same time, angular bearings offer a dependable option. They perform better in dynamic settings than conventional bearings. These bearings offer several advantages:

- Longer operating life

- Higher dynamic load carrying capacity

- Reduced friction

- Lower heat generation

Key Takeaways

- Angular bearings handle side and push forces, making them great for strong systems.

- Picking the right angle is important; small angles work for fast machines, big angles hold heavy weights.

- Taking care of bearings and adding oil makes them last longer, saving time and money.

- Angular bearings are useful in many fields like cars, planes, and green energy.

- Asking experts can help you find the best bearings for your needs.

What Are Angular Bearings?

Definition and Core Functionality

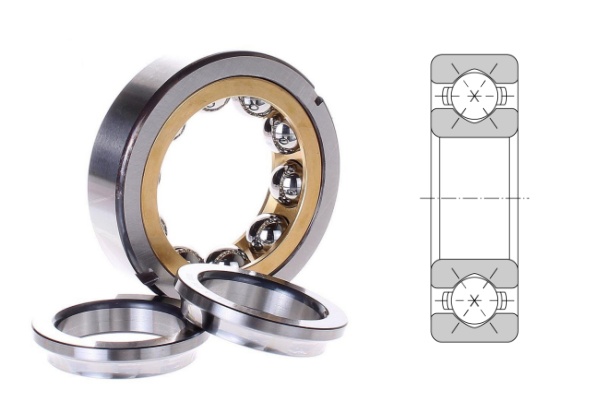

Specialized parts called angular bearings are made to control axial and radial forces at the same time. They perform exceptionally well in applications needing accuracy and stability under complicated loads, in contrast to conventional bearings. Effective load transfer from the inner race to the outer race is made possible by the balls that are positioned between the two races that make up these bearings. A key factor in how well the races and balls work is the angle of contact that forms between them. It establishes the bearing’s capacity to disperse forces and sustain precision while in use.

One characteristic that sets an angular bearing apart is its excellent torsional accuracy. For applications that need accurate movements, such machining operations, this function guarantees precise rotation. Furthermore, one property of angular bearings that increases their resistance to deflection under load is their moment stiffness.

Key Features and Variations

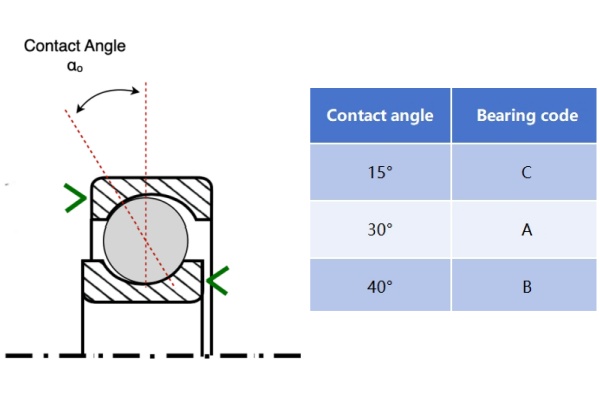

Angular bearings differ from other types of bearings in a number of important ways. They are adaptable for a range of applications due to their capacity to manage both thrust and radial loads. Their load capacity and speed performance are greatly influenced by the contact angle, which often ranges from 15° to 40°. High-speed applications are best served by bearings with a 15° contact angle, but larger loads are better supported by those with a 25° or 40° angle.

These bearings come in multiple variations to suit different needs. Applications needing accuracy and high-speed performance are best suited for single-row angular contact ball bearings. Double-row bearings provide more load capacity in a smaller package by combining two single-row bearings back-to-back. Specialized designs, such four-point contact bearings, can effectively withstand large axial stresses because of their two-piece inner ring.

Tip: When selecting angular bearings, consider the contact angle and load requirements to ensure optimal performance for your application.

Types of Angular Bearings

Angular bearings are available in several types, each tailored to specific performance needs:

| Type of Angular Bearing | Characteristics | Load Capacity | Contact Angle |

|---|---|---|---|

| Angular Contact Ball Bearing | High accuracy, good high-speed performance | Combined load | 15°, 30°, 40° |

| Matched Pairs (DB, DF, Tandem) | Configurations for load distribution | Varies | Varies |

| Double Row | Two single-row bearings matched back-to-back | Increased load capacity | Varies |

| Specialized (4-point contact) | Inner ring divided into two pieces | High load capacity | 35° |

The high shoulder on the outer ring of angular contact ball bearings, which increases their load capacity, makes them especially notable. These bearings can withstand heavier loads and reach faster speeds because to the contact angle’s intersecting lines. Flexible load distribution is offered by matched pairs, including tandem configurations, DF (face-to-face), and DB (back-to-back). Double-row bearings offer a compact solution for handling complex loads, while four-point contact bearings excel in applications requiring high axial force management.

Four-point contact bearing

How Angular Bearings Handle Complex Loads

Managing Radial and Axial Forces

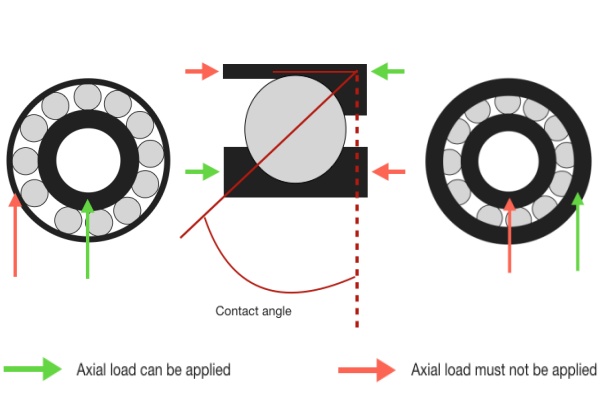

Angular bearings excel at managing both radial and axial forces, making them indispensable in high-performance systems. Axial forces line up along to the bearing’s axis, whereas radial forces act perpendicular to it. These bearings ensure balanced load distribution by transmitting axial loads through their rolling components and raceways. Even in variable conditions, its balance maximizes efficiency and reduces wear.

Single-row angular contact ball bearings handle radial forces obliquely, which means they transfer these forces at an angle relative to the bearing axis. This unique design allows them to manage combined loads effectively. However, when radial forces act on one bearing, they induce axial forces on adjacent bearings. This interaction highlights the importance of precise calculations when selecting bearings for your application.

Key performance metrics illustrate how angular bearings handle these forces:

| Metric | Definition | Relevance to Bearing Forces |

|---|---|---|

Dynamic Load Rating (C) | The load a bearing can sustain for 1 million revolutions without fatigue. | Indicates the bearing’s ability to handle varying forces during operation. |

| Static Load Rating (C0) | The maximum load a bearing can handle at rest without permanent deformation. | Crucial for applications with high static forces. |

| Equivalent Dynamic Load (P) | A calculated value combining radial and axial forces into a single load. | Ensures the bearing can handle the cumulative effect of both radial and axial forces. |

Understanding these features will assist you in selecting the ideal angular bearings for the longevity and functionality of your system.

The Importance of Contact Angles

In angular bearings, the contact angle is essential to their capacity to handle complicated loads. The distribution of forces inside the bearing is determined by this angle, which is created between the raceways and rolling elements. While bigger contact angles, like 40°, increase the bearing’s ability to withstand greater axial loads, smaller angles, like 15°, prioritize high-speed performance.

A bearing’s contact angle can be changed to maximize performance for various applications. For instance, in high-speed applications, a narrower contact angle results in smoother operation by lowering heat accumulation and friction. On the other hand, devices like rotors or turbines that must endure high axial forces benefit more from a larger contact angle. Choosing the contact angle that best meets your specific needs can significantly improve the operating efficiency of your bearing.

Studies have shown that optimal angular misalignment can extend the life of bearing-rotor systems. Additionally, a thin oil film at the ball-to-raceway interface enhances load capacity, a phenomenon known as elastohydrodynamics. These insights underscore the importance of selecting the right contact angle for your application.

| Study Title | Findings |

|---|---|

| Effect of Angular Misalignment and Axial Preload | Optimal angular misalignment extends the life of the bearing-rotor system. |

| Elastohydrodynamics (EHD Effect) | A thin oil film enhances load capacity at the ball-to-raceway interface. |

Stability and Precision in High-Stress Environments

Angular bearings are built to stay stable and accurate, even when things get tough. They don’t bend much under pressure, which keeps everything running smoothly. That’s why they’re a top choice in areas like robotics and aircraft, where everything has to work just right.

Angular bearing stability is further improved by preload methods. For example, fixed-position preload increases rigidity and decreases vibration, which makes these bearings perfect for applications requiring high speed and precision. Studies have shown that the dynamic characteristics of angular bearings are greatly influenced by elements such as inner ring interference and rotational speed.

| Study Title | Key Findings |

|---|---|

| A comparative study and stiffness analysis of angular contact ball bearings | Fixed-position preload enhances stability, while rotating speed affects dynamic properties. |

| Study on mass imbalance and wear characteristics | High-speed angular bearings maintain reliability and service life under mass imbalance conditions. |

Even under extreme conditions, angular bearings maintain their precision. Your systems will run more effectively because to this dependability, which lowers maintenance expenses and downtime. These bearings are a reliable option in a variety of industries due to their consistent performance, whether in renewable energy systems or industrial automation.

Advantages of Angular Bearings

Enhanced Load Capacity and Durability

Angular bearings are dependable for easily managing heavy loads. They are perfect for high-performance applications because of their special design, which enables them to concurrently control axial and radial forces. For example:

- The A-Type angular contact ball bearing excels in managing high axial loads. It also performs well in radial and combined radial-thrust applications.

- The load capacity of angular contact ball bearings is increased by their special structure. By reducing wear and friction, they guarantee durability even in high-speed machinery.

Angular bearings are a reliable option for systems needing long-lasting performance because of their characteristics. Their capacity to support large loads without sacrificing effectiveness guarantees that your equipment will run smoothly for extended periods of time.

Reduced Maintenance and Wear

Frequent maintenance is greatly reduced with angular bearings. Their long-lasting design reduces wear, extending service life and lowering operating expenses. Consider these statistics:

| Evidence Description | Key Benefit |

|---|---|

| They can last several times longer than traditional steel items. | This significantly reduces maintenance requirements and downtime. |

| They require less frequent maintenance than traditional steel bearings. | This leads to lower operational costs and less frequent need for lubrication. |

| Periodic inspections can help detect early signs of wear or contamination. | This proactive approach helps maintain optimal performance and extends bearing life. |

By utilizing angular bearings, you can reduce downtime and dedicate more attention to optimizing your processes. Their dependable nature guarantees consistent operation, even under tough circumstances.

Versatility Across Applications

Thanks to their ability to manage complex loads, angular bearings are used across a wide spectrum of industries.

They play a vital role in:

- High-speed operations in machine tools

- Precision-dependent aerospace components, like satellite reaction wheels

- Oil and gas drilling equipment that must endure shocks and harsh chemicals

- They’re also found in everyday technologies such as hard drives, spindles, and vehicle systems.

You’ll also find them in hard drives, motor spindles, and cars. In systems like pumps and gearboxes, where precision matters, they really shine. That’s why they’re a go-to solution for so many different applications.

Applications of Angular Bearings in Industries

Automotive: Steering and Transmission Systems

Angular contact ball bearings are an indispensable key component in automobiles, especially in the wheel hubs of the front and rear wheels. They not only support the weight of the entire vehicle, but also buffer the vibration caused by the road and the impact during braking, and provide stable support during cornering. Because they can withstand forces from multiple directions at the same time, the vehicle is safer and more stable during driving.

In the steering system, these bearings also play an important role. They connect the steering wheel and the steering rod, and can effectively deal with the lateral and axial forces when the vehicle turns, thereby reducing the shaking of the steering wheel and the deviation of the vehicle.

| Performance Benefit | Description |

|---|---|

| Low Torque | Reduces steering effort and improves fuel efficiency. |

| High Stiffness | Enhances control and responsiveness in steering and transmission systems. |

| Vibration Absorption | Dampens vibrations, ensuring quieter and more comfortable rides. |

The shift toward electric vehicles has increased the demand for high-precision bearings. These bearings support advanced technologies, ensuring durability and reliability in critical automotive applications.

Tip: Choose angular bearings with optimized load ratings and vibration tolerance for smoother vehicle performance.

Industrial Machinery: Robotics and Automation

Angular contact bearings are broadly applied across industrial machinery, including the critical fields of robotics and automation. They are frequently integrated into rotating components like electric motors, generators, and blade shafts, owing to their ability to deliver low friction and high rigidity during high-speed operation. Beyond precision automation, these bearings are also crucial for heavy-duty equipment such including cranes and excavators, designed to bear significant loads and demanding high levels of stiffness.

Tip: Select angular bearings designed for high-speed and high-precision tasks to maximize performance in robotics and automation.

Renewable Energy: Wind and Solar Systems

Angular bearings are necessary for long-term reliability and efficient operation in renewable energy systems. Even in the face of fluctuating wind conditions, these bearings maximize energy extraction by enabling the smooth rotation of wind turbine blades. Slewing ring bearings, which are used in solar panel mounting, provide precise alignment with the sun to optimize energy absorption. Bearings in solar panel gearboxes reduce friction, enhancing energy conversion efficiency and minimizing energy losses.

Renewable energy systems demand components that can withstand harsh environments and heavy loads. Bearings in these systems must resist corrosion caused by salt water and chemicals, especially in offshore wind farms. In order to maintain stability and durability over time, they must also manage heavy loads and shocks when in use.

Key Performance Metrics

Several performance indicators verify the efficacy of angular bearings in renewable energy systems:

| Performance Metric | Description |

|---|---|

| Reliability | Bearings operate stably for long periods under extreme conditions without failure. |

| Durability | High-quality bearings withstand harsh environments and heavy loads. |

| Corrosion Resistance | Bearings resist degradation from salt water and chemicals. |

| Load Capacity | Bearings handle significant loads and shocks during operation. |

| Energy Efficiency | Low friction technologies minimize energy losses and improve efficiency. |

| Ease of Maintenance | Bearings are designed for easy installation and maintenance in remote locations. |

These measurements emphasize how crucial it is to choose angular bearings that are specific to the requirements of renewable energy systems.

Why Angular Bearings Matter

You can rely on angular bearings to improve the efficiency and reliability of wind and solar systems. Their advanced design ensures smooth operation, even in challenging environments. By reducing friction and enhancing load capacity, these bearings contribute to the overall energy efficiency of renewable systems. Their durability and ease of maintenance make them an ideal choice for installations in remote or offshore locations.

Selecting the Right Angular Bearings

Factors to Consider: Load, Speed, and Environment

Environmental factors, load, and speed must all be carefully considered when selecting the appropriate angular bearings. The lifespan and performance of the bearing are directly impacted by each component.

- Load Requirements: Bearings need to be able to manage axial and radial forces efficiently. Prioritize bearings with higher dynamic load ratings (C) for dynamic applications. To avoid deformation in stationary systems, pay attention to static load ratings (C0).

- Speed Considerations: Bearings with minimal friction and optimal contact angles are necessary for high-speed operations. Ceramic materials perform well under these circumstances because they produce less heat and are resistant to wear.

- Environmental Factors: Harsh environments require bearings with corrosion-resistant materials and robust seals. For extreme temperatures, select bearings designed to maintain performance across wide temperature ranges.

| Material Type | Key Properties | Suitable Applications |

|---|---|---|

| Bearing Steel | Good hardness, toughness, and wear resistance. | Most applications. |

| Ceramic Materials | High hardness, low friction, and high corrosion resistance. | High-speed, high-temperature, or special environments. |

| Plastics and Composites | Reduced cost and weight for light-load or low-speed applications. | Light-load or low-speed applications. |

By matching the bearing’s specifications to your application’s demands, you can ensure optimal performance and durability.

Common Selection Mistakes

Avoiding common mistakes during the selection process can save you time and resources. Here are some pitfalls to watch for:

- Ignoring Lubrication Needs: Bearings in harsh environments often fail due to inadequate lubrication. For example, a mining excavator suffered a breakdown because its bearings lacked proper grease. Always choose lubrication suited to the operating conditions.

- Overlooking Maintenance: In medical devices, dirty bearings caused inconsistent results. Regular cleaning and inspections prevent contamination and extend bearing life.

- Misjudging Load Ratings: Selecting bearings without considering combined radial and axial forces leads to premature wear. Use equivalent dynamic load (P) calculations to ensure the bearing can handle cumulative forces.

Tip: Conduct periodic inspections and ensure proper lubrication to avoid costly failures.

Custom Solutions and Expert Guidance

Your particular needs might not always be satisfied by standard bearings. Tailored designs that tackle certain problems are offered by custom solutions. For instance, high-precision models improve robotic performance, and bearings with specific coatings prevent corrosion in offshore settings.

Consulting experts ensures you make informed decisions. Professionals analyze your system’s load, speed, and environmental conditions to recommend the best options. They also help you navigate performance metrics like fatigue life (L10) and temperature ranges.

| Metric | Definition | Relevance to Bearing Forces |

|---|---|---|

| Dynamic Load Rating (C) | The load a bearing can sustain for 1 million revolutions under dynamic conditions without fatigue. | Critical for assessing the bearing’s capability to handle varying and fluctuating forces during operation. |

| Fatigue Life (L10) | Expected life at which 90% of bearings will operate without failure under a specified load. | Predicts the bearing’s durability under operational forces. |

Note: Partnering with experts ensures your bearings meet industry standards and deliver reliable performance.

Thanks to their excellent precision and durability, angular contact bearings have fundamentally changed load management. Their ability to handle combined loads, operate at high speeds, and resist contamination makes them indispensable in many fields, including automotive and renewable energy, where they provide outstanding reliability and performance.

The market for angular bearings reflects their growing importance.

| Year | Market Value (Bn USD) | CAGR (%) |

|---|---|---|

| 2020 | 3.55 | N/A |

| 2027 | 5.30 | 6.9 |

Their versatility is evident when comparing leading brands.

| Feature | SKF Bearings | TIMKEN Bearings |

|---|---|---|

| Load Capacity | Exceptional load-carrying capacity for various applications. | Superior load-carrying capacity for heavy-duty applications. |

| Speed Capability | Designed for high-speed operation with optimized geometries. | Engineered for high-speed applications with stable performance. |

| Precision and Accuracy | Known for tight tolerances ensuring consistent performance. | Undergo rigorous quality control for precise tolerances. |

| Versatility | Offers a diverse range of bearings for various industries. | Provides a wide range of bearings tailored to different applications. |

Explore angular bearings to enhance your systems’ efficiency and reliability. Their proven performance ensures long-term success in any application.

FAQ

1. What makes angular bearings different from traditional bearings?

At the same time, angular bearings manage axial and radial forces. Better load distribution and accuracy are guaranteed by their special contact angle design. Conventional bearings frequently concentrate on a single force type, which reduces their adaptability in intricate applications.

2. How do I choose the right angular bearing for my system?

Examine the load, speed, and environment of your system. According to your needs, match the dynamic and static load ratings of the bearing. Smaller contact angle bearings are preferred for high-speed applications. Consult experts for tailored solutions.

3. Can angular bearings work in harsh environments?

Yes, angular bearings can operate well in harsh conditions because to sealed designs and corrosion-resistant materials. Because they can withstand contaminants like dust, water, and chemicals, they offer durability and dependability in challenging environments.

4. Are angular bearings suitable for renewable energy systems?

Absolutely! Angular bearings optimize wind turbine blade rotation and solar panel alignment. Their ability to handle heavy loads and resist corrosion makes them ideal for renewable energy applications, including offshore installations.

5. How often should angular bearings be maintained?

Inspect angular bearings periodically to detect wear or contamination. Proper lubrication extends their lifespan and ensures smooth operation. Maintenance frequency depends on the application and operating conditions.