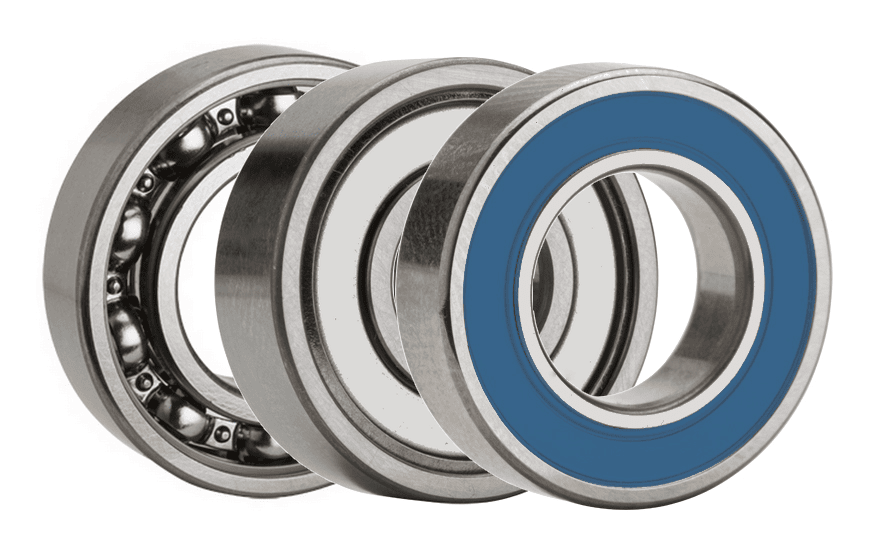

A Quick Comparison Table – Ball Bearing Material Types

| Part | Material | Strengths | Best For | Notes |

| Rings (Inner/Outer) | Chrome Steel (GCr15 / AISI 52100) | Very hard, wear-resistant, low cost | Motors, cars, general machines | Needs rust protection (oil/seal) |

| Stainless Steel (440C) | Rust-resistant, good in wet/humid areas | Food tools, marine use | Slightly softer than chrome steel | |

| Ceramic (Si₃N₄) | Light, fast, no rust, handles heat | High-speed, clean rooms | Expensive, brittle | |

| M50 / Cronidur 30 | Heat and corrosion resistant | Jet engines, wet high-load spots | Specialty materials | |

| Balls | Chrome Steel | Hard, long life, affordable | Most uses | Best all-around choice |

| Stainless Steel | Corrosion resistant | Moist or food-related use | Lower load ratings | |

| Ceramic (Si₃N₄ / ZrO₂) | Ultra-smooth, low friction, rust-proof | High speed, chemicals | High cost, ZrO₂ weaker at high heat | |

| Tungsten Carbide (WC) | Very strong, handles heavy loads | Heavy machinery | Rare, expensive | |

| Cage | Steel | Strong | General purpose | May rust |

| Brass | Durable, corrosion-resistant | High-speed bearings | Good at resisting friction | |

| Stainless Steel | Corrosion/heat resistant | Harsh environments | Longer life | |

| Nylon (PA66) | Lightweight, low friction | Moderate speed/load | Not for very hot places | |

| PTFE (Teflon) | High temp, no oil needed | Dry or chemical uses | Softer | |

| PEEK | Very high temp resistance | High-speed, industrial setups | Expensive | |

| Seals/Shields | Rubber Seals | Full protection, blocks dirt & water | Outdoor, wet or dusty work | Slight drag on speed |

| Metal Shields | Basic protection, high-speed ready | Clean/dry machines | Not waterproof | |

| PTFE Seals | Handles heat & chemicals | Food, lab, or chemical setups | Specialized use |

Introduction

Imagine a race car speeding on a hot track, a boat motor splashing through salty waves, or a food factory where machines need to stay super clean.

Each of these needs ball bearings, but not the same kind! Ceramic ball bearings handle the heat and speed of racing, stainless steel ball bearings fight rust in wet boat engines, and plastic ball bearings keep things light and clean in food plants.

The material in a ball bearing makes all the difference for how it works. In this article, you’ll learn about the main types of ball bearing materials and where they shine. Let’s check them out!

Inner and Outer Ring Common Materials

The rings in a bearing hold everything together. They take on the pressure from spinning and keep the balls in place. Because of this, the material needs to be super strong and stable.

What They Need To Do:

- Handle both side and up-down pressure

- Stay strong under spinning and heat

- Keep their shape over time

Strong and Reliable Steel for Rings

Steel is the most common stuff for these rings.

A very popular choice is high carbon chrome steel ball bearings, known as GCr15 in China or AISI 52100 in other places.

This steel is super strong! It gets its strength from having a good amount of carbon in it, plus about 1.5% of the metal chrome.

This mix makes it a great all-around steel for bearings. It helps them last a long time and handle loads well when they’re rolling and working hard.

This kind of ball bearing steel is used in tons of places like electric motors, power tools, car parts, and big factory machines. They’re strong and last long, which is great. These are the classic chrome ball bearings you see often.

The main thing to remember is that this material doesn’t like getting wet. It needs oil or some kind of protection to stop it from rusting, especially if it’s going to be around moisture.

There are also special steel rings for tough jobs. For example, for places that get really hot, like in airplane engines, special high-temperature steels like M50 are used because they stay strong even in extreme heat.

And for places that are wet but maybe not as harsh as needing full stainless steel rings, there’s a type of stainless bearing steel like Cronidur 30 that offers good rust fighting while still being strong.

Stainless Steel Rings (Like AISI 440C)

What if the rings need to work where they might get wet or be around chemicals that cause rust? That’s when stainless steel ball bearings rings are needed.

Steels like AISI 440C are popular for this. They have a lot of chrome (about 18%) which is great at fighting rust and corrosion in places with high humidity or even some mild chemicals.

These rings are used in equipment near the sea, in food factories, and in clean rooms.

While stainless steel rings like 440C are a little less hard than 52100 chrome steel rings, their ability to resist rust is a huge advantage. This means they handle slightly less load, but they work great in wet or corrosive spots.

So, if you see ss ball bearing or stainless ball bearings used for the rings, you know they’re built to handle challenging environments.

Ceramic Rings (Like Si₃N₄)

For the most extreme jobs, the bearing rings might be made of ceramic, like Silicon Nitride (Si₃N₄). These rings are incredibly hard and smooth.

They are perfect for situations needing super high speeds. They also work well in places that get extremely hot or need no lubrication.

Ceramic rings are much lighter than steel. They resist wear and corrosion extremely well. Plus, they don’t conduct electricity or get affected by magnets.

This makes them great for high-speed motors, aerospace stuff, and very precise tools.

The downsides are they cost a lot more than steel rings. They can also be brittle, meaning they might crack if hit hard.

You’ll often find ceramic rings in very demanding applications. Sometimes you’ll see a hybrid where ceramic rings are used with different balls, like in some ceramic angular contact bearings.

Carbon Steel Ball Bearings for Simple Jobs

For very simple, low-cost bearings used in things like toys or light carts, you might find parts made from basic carbon steel ball bearings.

This steel is less processed than the special bearing steels we talked about. It’s okay for light weight and basic rolling.

However, it’s not very hard, wears out faster, and rusts very easily if it gets wet.

You’ll only see this kind of basic metal ball bearing material in applications where performance isn’t critical and cost is the main focus.

Plastic Ball Bearings for Special Needs

Yep, the rings and balls can also be made from plastic! Materials like Nylon or PTFE (often called Teflon) are used.

Plastic ball bearings are super useful because they are very light. They don’t need much (or any) grease sometimes.

Importantly, they don’t rust at all and can resist many chemicals. They also don’t conduct electricity and aren’t magnetic.

They can’t handle as much weight or speed as metal or ceramic. So, you’ll find them in lighter-duty jobs. They are great for places where chemicals, water, or electricity are present, and metal isn’t suitable.

Ball Materials: The Rolling Part

The balls take on all the movement. They need to be smooth, strong, and long-lasting.

What They Need To Do:

- Keep friction low

- Stay tough under pressure

- Resist wear over time

What Are Ball Bearing Balls Made Of?

The balls are made from materials similar to the rings, chosen for their specific job:

Steel Balls

The most common are made from high-quality ball bearing steel like 52100 chrome steel. These are hard and strong for general use.

For fighting rust, stainless steel ball bearings (like 440C) are used as balls in bearings for wet or corrosive spots. They are slightly less hard than 52100 but resist rust much better.

Ceramic Balls

Balls made of ceramic, usually Silicon Nitride (Si₃N₄) or sometimes Zirconia (ZrO₂), are used for demanding jobs. Si₃N₄ balls are amazing for super high speeds, resisting heat, and not conducting electricity or rusting. ZrO₂ balls are very strong, but not quite as good at high temperatures as Si₃N₄. Ceramic balls have lower density, which helps at high speeds by reducing force pushing outwards. They are often used in hybrid bearings with steel or stainless rings, like in stainless steel angular contact bearings with ceramic balls.

Tungsten Carbide Balls

For situations with extremely heavy loads, like in some big industrial machines, balls made of Tungsten Carbide might be used. This material is incredibly hard and strong, perfect for very high load tasks, but it costs a lot more.

Plastic Balls

Used in full plastic bearings for light loads where non-metal features are needed.

The material of the ball is key to how well the bearing rolls, how fast it can spin, and how much weight it can handle smoothly. It also affects if it can work in special conditions like high heat or wetness.

Cage Materials – What Holds the Balls in Place

The cage is the part that sits between the inner and outer rings. It keeps the ball bearing balls separated evenly.

This job is important for smooth running and longer bearing life, especially at higher speeds. Cages need to be relatively light and resist wear from touching the balls.

Metal Cages

Cages can be made from different metals. Pressed steel cages are very common.

They are strong, reliable, and not too expensive. They are good for many general uses at moderate speeds.

For higher speeds or places with vibration, cages made of brass (a copper alloy) are often used. Brass is tougher and wears better in these conditions, though it costs more.

Stainless steel cages are also used in corrosive or high-temperature environments to match the rings or balls in stainless steel ball bearings.

These various metal ball bearings use metal cages suitable for their intended use.

Engineered Plastic Cages

Many bearings, especially those in electric tools or household appliances, use cages made from strong plastics called engineered plastics.

Polyamide (like Nylon 66) is a common one. It’s light, has low friction, and works well for medium loads and speeds. It often helps make the bearing quieter.

PTFE (Teflon) cages can handle high temperatures and are used in bearings that don’t use grease or oil.

For very high speeds and temperatures, a plastic called PEEK is used for cages.

Plastic cages are great because they are light and have low friction against the balls. But they have temperature limits compared to metal or ceramic. The cage material is one of the things that can vary, especially in custom ball bearings.

Seals and Shields – Protecting What’s Inside

To keep dirt, dust, and water out of a bearing and keep the good stuff like grease or oil in, bearings often have seals or shields on the sides.

Rubber Seals (NBR, Viton)

These are flexible rings, often made from types of rubber like NBR or Viton. They fit snugly against the inner ring, creating a good seal.

Rubber seals are excellent for protecting the inside of the bearing from water, dust, and dirt. This makes them great for use in messy or wet environments.

They are great at keeping water, dust, and dirt out, and keeping the lubrication inside.

Metal Shields

Metal shields are thin pieces of metal fitted into the outer ring. They sit very close to the inner ring but usually don’t touch it.

They act like a barrier to keep out larger dirt or dust particles in cleaner environments.

Since they don’t rub, metal shields allow the bearing to spin faster than seals. But they don’t offer as complete protection against liquids or fine dust.

PTFE (Teflon) Seals

Seals made from PTFE (often called Teflon) are used in special situations.

This material can handle much higher temperatures. It also resists harsh chemicals that would damage other seal materials.

You’ll find these in specific industrial bearings dealing with extreme heat or corrosive substances

How to Choose the Right Ball Bearing Material

So, with all these different materials for the rings, balls, cages, and seals, how do you figure out which ball bearing you need for your project?

It really comes down to thinking about the specific conditions where the bearing will work. Ask yourself:

- Will it be exposed to water, chemicals, or dirt? (Think stainless steel, plastic, special seals)

- How fast will it spin, and how much weight will it carry? (Think steel, ceramic, Tungsten Carbide for balls, specific cage materials)

- What will the temperature be? (Think special high-temp steels, ceramics, PEEK plastic)

- Does it need to not conduct electricity or be non-magnetic? (Think ceramic, plastic)

- Does it need to run quietly or without much lubrication? (Think plastic cages, certain materials)

Often, the best bearing is a combination of materials. For example, a stainless steel bearing with rubber seals for a wet environment. Or a hybrid bearing with ceramic balls for speed in a steel ring.

Looking at a ball bearing types chart can be helpful to see the different types and their typical materials and uses side-by-side.

If your needs are very specific, don’t worry! You can often get custom ball bearings made with just the right mix of materials for your unique situation.

Get the Right Bearing from TFL

Picking the right material for your ball bearing bearings is a big step. It helps make sure your machine or product works smoothly, lasts a long time, and performs correctly in its specific environment.

The materials used for the rings, balls, cage, and seals all affect the bearing’s strength, speed ability, how well it handles heat or water, and even its cost.

It might seem like a lot to think about, but you don’t have to figure it out alone! We at TFL Bearings make all sorts of high-quality ball bearings using the materials we’ve talked about, including custom ball bearings.

We understand how important it is to have the perfect fit for your needs.

Ready to find the best ball bearing for your project? Have questions about which material is right? Check out our website to see our range and learn more! Or, just contact us directly – we’re experts in bearing materials and applications, and we’re here to help you choose the perfect bearing and even create custom solutions for you!

Questions About Ball Bearing Materials

Why are ceramic ball bearings often used for very high speeds?

Ceramic materials like Silicon Nitride are much lighter and harder than steel. This helps them spin faster with less force pushing outwards and less rubbing.

What’s the main difference between 52100 chrome steel and 440C stainless steel for bearings?

The biggest difference is fighting rust. 440C stainless steel has a lot more chrome than 52100 steel. This makes 440C much better at resisting rust and corrosion, especially in wet places.

When would you need a plastic ball bearing?

Plastic bearings are useful when you need something very light, that won’t rust at all, doesn’t carry electricity, resists chemicals, or needs little grease. They are for lighter jobs than metal bearings.

Are the balls always made of the same material as the rings in a bearing?

Not always! Sometimes bearings mix materials, like ceramic balls in steel rings. This is done to combine benefits, like getting high speed from the ceramic balls with the strength of steel rings.

Why are there different materials for the cage?

The cage material depends on how fast the bearing spins, the temperature, and the place it’s used. Metal cages are strong. Plastic cages are lighter and quieter but have temperature limits. Ceramic cages are for extreme heat and speed.