As modern machinery continues to evolve toward lighter, more compact, and more efficient designs, engineers face increasing challenges in managing space without sacrificing performance. Bearings, which play a critical role in load support and motion control, must adapt to these constraints. This is where thin-section bearings have become an essential solution.

Thin-section bearings are specifically engineered to provide reliable rotational performance while occupying minimal space. Their unique geometry allows designers to reduce weight, save space, and maintain precision, making them ideal for advanced mechanical systems where traditional bearings are too bulky. This article explores what thin-section bearings are, their advantages, available designs, and the best use cases in space-saving machinery.

What Are Thin-Section Bearings

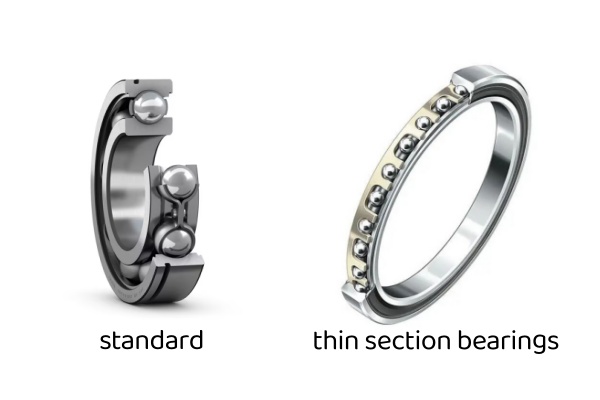

Thin-section bearings are rolling bearings characterized by a very slim cross-sectional profile relative to their bore diameter. Unlike standard bearings, where cross-section increases as bore size increases, thin-section bearings maintain a consistent cross-section across different diameters.

This design allows thin-section bearings to fit into tight spaces while still providing accurate rotational motion and load support. They are commonly manufactured with ball rolling elements and are available in various configurations depending on load direction and application requirements.

Key Design Characteristics of Thin-Section Bearings

One defining feature of thin-section bearings is their constant cross-section. This allows designers to scale bearing diameter without increasing radial or axial space requirements. As a result, machine layouts can be simplified and overall system weight reduced.

Thin-section bearings are typically manufactured with high precision to ensure smooth motion, minimal runout, and consistent performance. Because of their slim profile, material selection, heat treatment, and raceway geometry are carefully optimized to balance strength and durability.

Advantages of Thin-Section Bearings

One of the biggest advantages of thin-section bearings is space efficiency. Their slim profile allows them to fit into compact assemblies where traditional bearings cannot, enabling more flexible and innovative machine designs. Weight reduction is another major benefit. Thin-section bearings help create lighter overall systems, which is especially crucial in applications where inertia, energy use, or dynamic performance matter. Lighter bearings also improve responsiveness in moving systems. Additionally, thin-section bearings provide excellent rotational accuracy. Their precise manufacturing makes them suitable for applications requiring smooth motion, low torque, and low vibration. The combination of compactness, light weight, and accuracy makes them very valuable in advanced engineering projects.

Load Capacity and Performance Considerations

Thin-section bearings are designed to handle moderate loads relative to their size. While they may not match the load capacity of larger, heavier bearings, they perform exceptionally well when loads are properly distributed and aligned.

Because of their thin raceways, these bearings are more sensitive to mounting accuracy and housing rigidity. Proper support and alignment are essential to ensure even load distribution and to prevent localized stress. When used correctly, thin-section bearings provide reliable performance with minimal friction and wear.

Types of Thin-Section Bearings

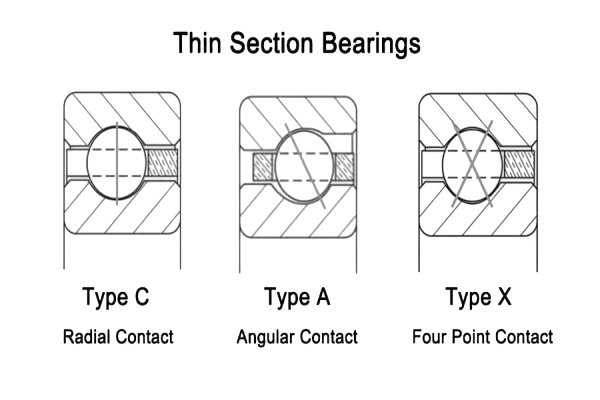

Thin-section bearings are available in several designs to accommodate different load conditions. Radial contact thin-section bearings are suitable for applications with primarily radial loads. Angular contact thin-section bearings can handle combined radial and axial loads and are often used in pairs for added stability.

Four-point contact thin-section bearings are designed to support axial loads in both directions and radial loads. This makes them particularly useful in applications where space constraints prevent the use of multiple bearing arrangements.

Each design offers unique advantages, and selecting the correct type depends on load direction, stiffness requirements, and operating conditions.

Recommended SDTFL Thin-Section Series for Your Machinery

To help you select the right component, here are the most popular series we manufacture for space-constrained applications:

- 6700, 6800, 6900 Series (Metric): The industry standard for metric thin-section needs. Available in Open, ZZ (Shielded), and 2RS (Sealed) variations.

- KAA to KG Series (Inch): Constant section bearings ideal for aviation and US-standard equipment.

- Type C (Radial Contact): Optimized for pure radial loads with deep grooves.

- Type A (Angular Contact): Perfect for combined loads and high-precision assemblies.

- Type X (Four-Point Contact): The ultimate space-saver, handling radial, axial, and moment loads in a single bearing.

View Full Catalog: See detailed specifications for Type C, A, and X bearings on our Product Series Page.

Thin Section Bearings vs Standard Bearings

Compared to standard bearings, thin-section bearings offer superior space and weight efficiency. Standard bearings increase in size and weight as bore diameter increases, which can limit design flexibility. Thin-section bearings eliminate this limitation by maintaining a constant cross-section.

However, thin-section bearings generally require more precise installation and support. Their slim structure means they rely more heavily on housing stiffness and shaft accuracy. When these factors are properly controlled, thin-section bearings can outperform standard bearings in compact systems.

Best Use-Cases for Thin Section Bearings

Thin-section bearings are widely used in applications where space and weight savings are critical. Robotics and automation systems frequently rely on thin-section bearings to achieve compact joint designs and smooth motion. In these systems, reduced inertia improves speed, accuracy, and energy efficiency.

Medical equipment is another key area where thin-section bearings excel. Imaging devices, diagnostic machines, and surgical equipment benefit from compact designs and precise motion control. Thin-section bearings help meet these requirements while maintaining reliability.

Aerospace and defense applications also extensively use thin-section bearings. In aircraft systems, satellites, and uncrewed vehicles, minimizing weight while maintaining performance is essential. Thin-section bearings contribute to lighter structures and improved system efficiency.

Industrial equipment such as rotary tables, indexing systems, and packaging machinery also benefits from thin-section bearings. Their ability to support precise rotation in confined spaces allows for more efficient machine layouts and improved productivity.

Role of Thin Section Bearings in Space-Saving Machinery

In space-saving machinery, every component must contribute to compactness without compromising function. Thin-section bearings enable designers to reduce housing size, eliminate unnecessary elements, and integrate motion systems more efficiently.

Their slim profile also allows for larger shaft diameters within the same envelope, thereby improving shaft stiffness and overall system stability. This combination of compact bearing design and enhanced structural performance makes thin-section bearings a preferred choice in modern machinery.

Optimize Your Design: Don’t let bulky bearings dictate your machine’s size. Collaborate with SDTFL to achieve the ultimate compact design. Reach out via WhatsApp/WeChat: +86 15806631151.

Installation and Handling Considerations

Due to their precision and thin structure, thin-section bearings must be handled with care during installation. Improper mounting or uneven housing support can lead to distortion, increased friction, and reduced bearing life.

It is essential to ensure that shafts and housings meet specified tolerances and that mounting surfaces are clean and properly aligned. Using appropriate tools and following recommended installation procedures helps preserve bearing performance and longevity.

Maintenance and Service Life

Thin-section bearings typically operate with low friction and minimal wear when properly installed and lubricated. Depending on the application, they may be lubricated with grease or oil. Sealed versions are also available to reduce maintenance requirements in contaminated environments.

Routine inspection and condition monitoring help ensure continued reliability. Because thin-section bearings are often used in precision systems, early detection of wear or misalignment is particularly important.

Thin-section bearings are a vital solution for modern space-saving machinery. Their compact design, reduced weight, and high precision make them ideal for applications where traditional bearings are impractical. By enabling efficient use of space without sacrificing performance, thin-section bearings support innovation across industries such as robotics, medical technology, aerospace, and advanced industrial equipment.

Understanding their advantages, limitations, and best use-cases allows engineers and buyers to select thin-section bearings that deliver reliable, efficient, and long-lasting performance in compact mechanical systems.

Partner with SDTFL Bearings for Compact Precision

At SDTFL Bearings, we understand the challenges of modern mechanical design. Space is at a premium, and precision cannot be compromised. As a dedicated factory manufacturer, we specialize in producing high-quality thin-section bearings that empower your machinery to be lighter, faster, and more efficient.

Whether you are designing the next generation of medical robots or upgrading industrial rotary tables, we have the manufacturing capacity and engineering expertise to support your needs. By sourcing directly from our factory, you ensure consistent quality control and competitive B2B pricing.

Take the next step in optimizing your machinery:

- Get a Fast Quote: Send your requirements to info@sdtflbearing.com

- Speak to an Expert: Call us at +86 15806631151 for immediate technical assistance.

- Browse Our Solutions: Click here to view our full Thin-Section Bearing Catalog

Let’s build the future of compact machinery together. Contact Us today!