Key Polymer Materials for Bearing Seals

Key polymer materials for bearing seals include NBR, FKM, PTFE, silicone, and polyurethane, each offering unique protection and durability.

Key polymer materials for bearing seals include NBR, FKM, PTFE, silicone, and polyurethane, each offering unique protection and durability.

Choose the right angular contact bearings for 5-axis CNC machines by matching load, speed, and precision needs to boost accuracy and extend machine life.

Ever wondered what makes heavy equipment glide effortlessly? It’s often the humble roller ball caster! Dive into the mechanics of these small but mighty components that enable seamless multidirectional movement.

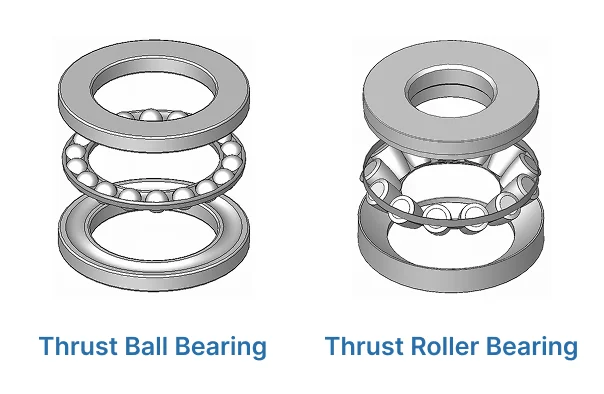

Thrust bearings and washers boost machine speed, load, and lifespan by up to 50% by reducing friction, wear, and heat for reliable, efficient operation.

High-temperature failure in machinery bearings can halt harvests. See how a Brazilian farmer solved this issue and learn prevention strategies for your farm.

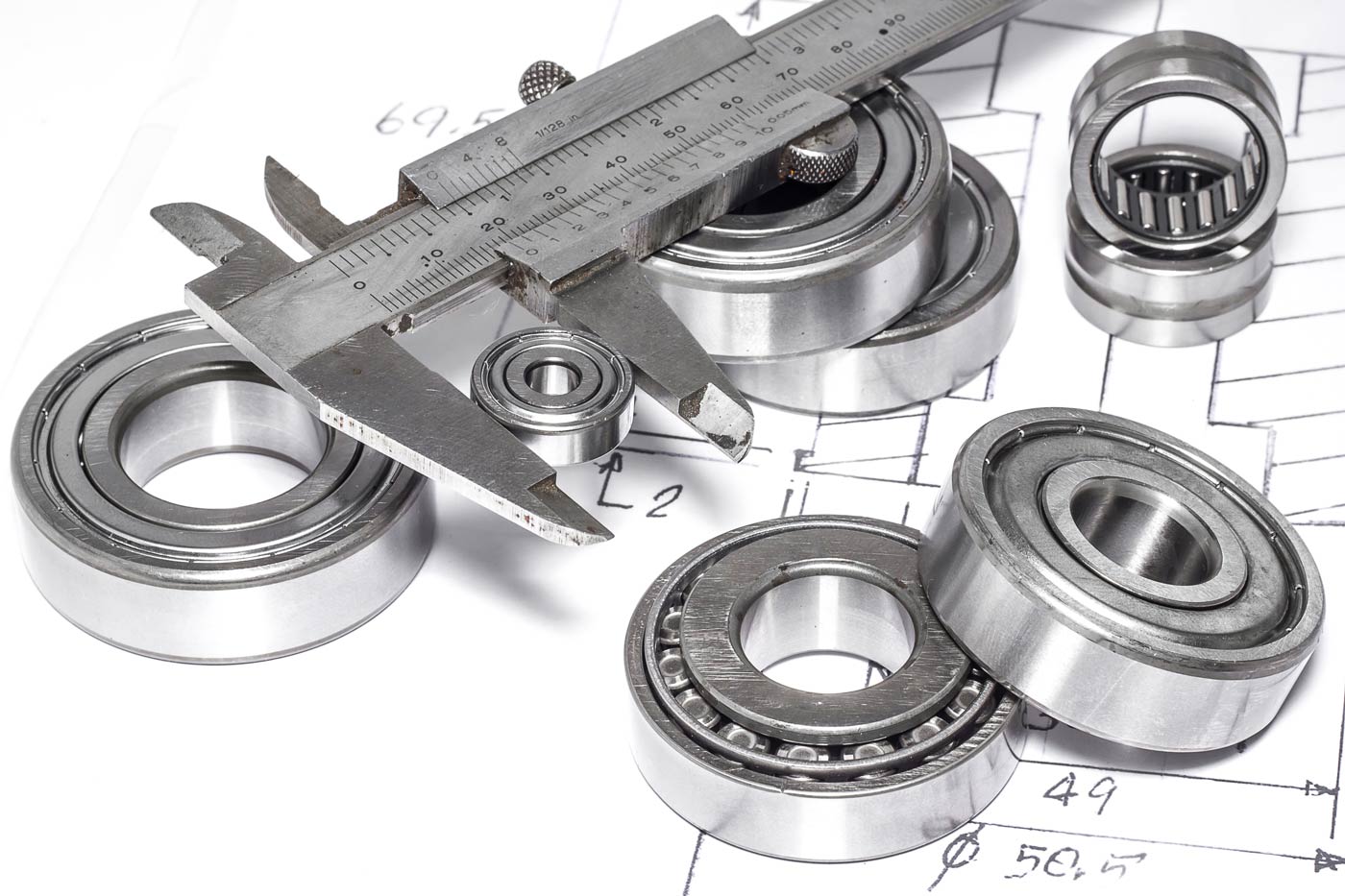

Compare roller bearing vs ball bearing to see which suits heavy loads or high speeds. Find key differences and best uses for your machinery needs.

High precision ball bearings offer tighter tolerances, longer life, and lower vibration than standard types—worth the cost for demanding applications.

3D printing bearings enable custom designs, rapid prototyping, and cost savings, but face material limits. See trends, benefits, and industry adoption insights.