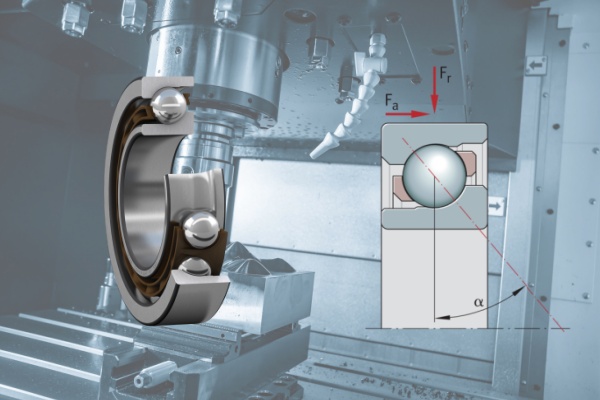

Angular Contact Ball Bearings: Features, Benefits, and Best Applications

This article explores the design, functionality, and benefits of angular contact ball bearings, highlighting their ability to handle combined loads in high-speed industrial applications like robotics and automotive systems.