Knowledge Center

Enhancing Serviceability: Smart Mounting and Efficient Dismounting of Bearings

Here’s an alarming fact: approximately 16% of all premature bearing failures are not caused by quality or selection issues, but by improper mounting. Using a hammer to brutally strike a bearing can not only cause internal damage to a costly precision component in an instant, but it also plants a hidden seed for future equipment failure.

The shift from “brute-force hammering” to “professional procedures” reflects a deeper understanding of equipment reliability. This article introduces modern mounting and dismounting methods that not only protect the bearing but also enhance the serviceability of your equipment throughout its entire lifecycle.

Section Navigation

How to Choose the Right Bearing

- P0: The 8-Step Practical Guide to Systematic Bearing Selection

- C1: A Guide to Correctly Select a Bearing Type Based on Load, Direction, and Space

- C2: Bearing Arrangements: A Guide to Locating-Non-locating and Paired Mounting

- C3: How to Verify Bearing Size and Accurately Assess Its Lifespan

- C4: The Core of High-Precision: Balancing Speed, Precision, Fits, and Clearance

- C5: A Guide to Bearing Preload and System Rigidity Design

- C6: Choosing the Optimal Lubrication Strategy for Your Bearings

- C7: Key Design Points for Bearing-Related Components (Shaft, Housing, and Seals)

- C8: Smart Mounting and Efficient Dismounting of Bearings

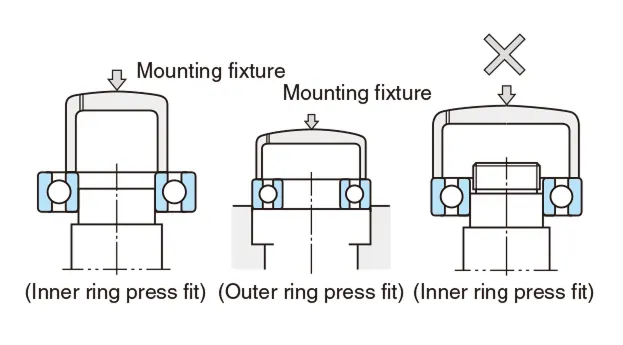

The Core Principle: Apply Force Only to the Ring Being Fitted

This is the golden rule that must be followed in all mounting operations, regardless of the tool you use.

- When mounting the inner ring, apply force to the inner ring.

- When mounting the outer ring, apply force to the outer ring.

- When mounting both rings simultaneously, apply force evenly to the faces of both rings.

Why? Imagine you apply force to the outer ring while trying to press-fit the inner ring onto a shaft. The mounting force will be transmitted through the rolling elements. This will create permanent dents (brinelling) on the delicate raceways. From the very first rotation, this damage will be a source of vibration and noise, leading to rapid premature failure.

Modern Mounting Techniques: Goodbye, Hammer

Cold Mounting (Mechanical Methods)

- Fitting Tool Kits (Sleeves & Impact Rings): These are the most basic and essential professional tools. They ensure that the mounting force is applied evenly and perpendicularly to the correct ring face. Perfect for small to medium-sized bearings.

- Hydraulic Press: Provides smooth, controllable pressure, making it the ideal choice for achieving a perfect interference fit.

Hot Mounting (Thermal Expansion Method)

This is the most common method for mounting medium to large bearings, utilizing the principle of thermal expansion.

- Induction Heaters: The highly recommended, first-choice solution! They act like a “specialized induction cooktop for bearings,” providing uniform, fast, and clean heating with precise temperature control to prevent the bearing from being overheated and damaged.

- Comparison: Why are oil baths being phased out? Oil baths not only contaminate the bearing and the environment but also pose a safety hazard (risk of burns) and make it difficult to control the temperature evenly.

Safety Tip: The heating temperature should generally not exceed 120°C (250°F). Always wear proper heat-resistant gloves during handling.

Hydraulic Method

This is the “heavy artillery” for mounting large and extra-large bearings. High-pressure oil is injected between the mating surfaces, causing the inner ring to “expand” and allowing it to be effortlessly pushed onto a tapered shaft journal.

Dismounting Techniques: Avoiding Damage on the Way Out

The goal of dismounting is to remove the bearing safely without damaging the shaft and housing—which are often expensive components.

Mechanical Pullers

- Two/Three-Jaw Pullers: The most common dismounting tools. The key to using them correctly is to ensure the puller’s jaws are applied to the ring that has the interference fit. For example, when removing a bearing that is tight on the shaft, the jaws must pull on the inner ring, not the outer ring.

- Internal / Blind Hole Pullers: Specialized tools for removing bearings fitted in blind housings.

Hydraulic-Assisted Techniques

For large bearings with a tight fit, purely mechanical pulling can be strenuous and dangerous. Using hydraulic nuts or hydraulic pullers applies immense, steady force, making the dismounting process easy and safe.

Hot Dismounting

The reverse of hot mounting. Specialized heating rings or induction heaters are used to rapidly heat the bearing outer ring (if it has an interference fit in the housing), causing it to expand and disengage.

Designing for Serviceability from Day One

The most advanced maintenance begins in the earliest design phase. A great designer always considers future maintenance scenarios.

- Provide Space for Dismounting: Design shallow grooves or slots behind the shaft shoulder or on the housing end cover. This provides a secure grip for a puller’s jaws. A small design feature can save a maintenance technician hours of work.

- Use Tapered Bore Bearings with Adapter/Withdrawal Sleeves: This is the “golden combination” for mounting and dismounting medium-to-large bearings. By simply tightening or loosening a nut, the bearing can be easily secured or released, dramatically simplifying fieldwork.

- Choose Split Housings or Split Bearings: For hard-to-reach locations, these designs allow a bearing to be replaced without having to dismount the entire shaft, significantly reducing downtime.

Professional Mounting and Maintenance is the Best Investment in Reliability

Whether a bearing achieves its full design life comes down to the critical “last mile” of proper mounting and dismounting. Integrating serviceability into the design and insisting on using professional tools and correct procedures are not just about protecting the bearing—they are smart investments in the long-term reliability of your equipment and in lowering its total lifecycle cost (LCC).

Not finding what you need?

If you have enquiries about our product or solutionservice, please contact us via email.