Knowledge Center

What Are the Differences Between Bearings? A Guide to the Bearing Family

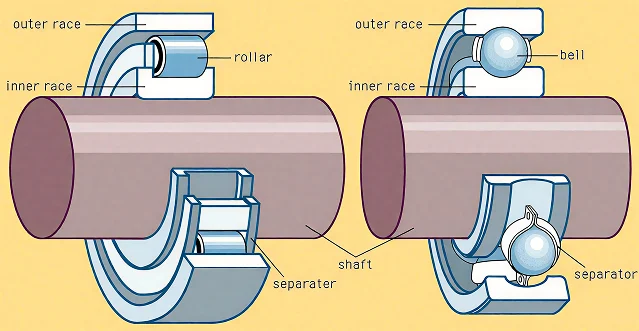

Bearings may look similar from the outside, but inside, they are very different. Think of vehicles: some are sports cars built for speed, others are trucks built for power. In the same way, bearings are divided into two main families based on their “rolling elements”: Ball Bearings and Roller Bearings.

Today, let’s explore these two families and see what each member is good at.

Section Navigation

#1 What is a Bearing?

#2 Bearing Knowledge for Beginners

#3 Operation Guide for Bearings After Arrival

The Core Difference: “Sprinters” vs. “Weightlifters”

Before we dive deep, let’s understand the most important difference:

Ball Bearing

The rolling elements are balls. The ball makes “point contact” with the raceway, like a single marble on a flat surface.

- Pros: Small contact point means less friction. This allows for very high speeds and quiet operation.

- Cons: Small contact point means it can only support limited loads.

- Analogy: They are the “sprinters” of the bearing family, built for speed.

Roller Bearing

The rolling elements are various types of rollers (cylindrical, tapered, needle, etc.). The roller makes “line contact” with the raceway, like a soda can lying on a table.

- Pros: Long contact line means it can support much heavier loads. They are very strong.

- Cons: Larger contact area creates more friction. Their maximum speed is usually lower than ball bearings.

- Analogy: They are the “weightlifters,” born to handle heavy duties.

With this key difference in mind, let’s meet the star members of each family.

The Ball Bearing Family: Representatives of Speed and Agility

Deep Groove Ball Bearing

- Features: It has the simplest structure and is the most widely used type. It’s the “all-rounder” of bearings. The deep grooves on its rings hold the balls well.

- Best for: High-speed rotation. It can handle radial loads (from the side) and some axial loads (from the ends) in both directions.

- Applications: Electric motors, home appliances (washing machines, fans), skateboards.

Angular Contact Ball Bearing

- Features: Its inner and outer raceways are specially designed with a “contact angle.” This makes it ideal for supporting combined loads.

- Best for: Handling both radial loads and axial loads in a single direction. They are often used in pairs to support axial loads from two directions.

- Applications: Spindles of precision machine tools, high-frequency motors.

Self-aligning Ball Bearing

- Features: It has two rows of balls and a spherical outer raceway. This smart design gives it a “self-alignment” ability.

- Best for: Situations where the shaft might bend or there is an alignment error during installation. It can adjust itself to run smoothly.

- Applications: Agricultural machinery, textile machines, conveyor belts.

The Roller Bearing Family: Symbols of Strength and Durability

Cylindrical Roller Bearing

- Features: The rollers are perfectly cylindrical.

- Best for: Supporting very heavy radial loads. Its radial load capacity is among the highest of all bearing types. It typically cannot handle axial loads (unless specially designed).

- Applications: Large motors, gearboxes, and machine tool spindles.

Tapered Roller Bearing

- Features: Both the rollers and the raceways are cone-shaped (tapered).

- Best for: Handling heavy “combined” loads. This means it can support large radial loads and large axial loads at the same time.

- Applications: Car wheel hubs, industrial gear reducers, steel rolling mills.

Spherical Roller Bearing

- Features: The rollers are barrel-shaped, and the outer raceway is spherical. It combines the benefits of “self-alignment” and “super-high load capacity.”

- Best for: The heaviest loads and severe misalignment. It is one of the toughest and strongest members of the b

- earing family.

- Applications: Mining machinery, paper mills, and vibrating screens where conditions are extremely harsh.

Needle Roller Bearing

- Features: The rollers are very thin and long, like needles.

- Best for: Providing a very high load capacity in a very small space. It has the smallest cross-section of all roller bearings.

- Applications: Automotive transmissions, motorcycle engines, and power tools where space is limited.

Choose the Right Tool for the Job

There is no “best” bearing, only the “most suitable” one. The choice between a ball bearing and a roller bearing depends on whether your machine needs more speed or more strength. The specific type you choose depends on factors like load direction, available space, and alignment requirements. By understanding their features, you can find the perfect rotating partner for your equipment.

Not finding what you need?

If you have enquiries about our product or solutionservice, please contact us via email.