Knowledge Center

Bearing Storage Skills: How to Manage Bearings and Protect Your Investment

A spare bearing is like an insurance policy for your equipment, a critical investment for unexpected breakdowns. But have you ever thought about what would happen if that “insurance” was already rusted, contaminated, or damaged when you needed it most? Improper storage can cause your spare bearings to fail before they even start.

Today, let’s learn how to store and manage your spare bearings like a professional.

Section Navigation

#1 What is a Bearing?

#2 Bearing Knowledge for Beginners

#3 Operation Guide for Bearings After Arrival

Why is Proper Storage So Important? The Dangers of Bad Storage

Bearings are precision components and are very sensitive to their environment. Improper storage can directly lead to the following problems:

- Corrosion: This is the most common killer. Moisture in the air can get through damaged packaging and create rust spots on the bearing surfaces. These spots can lead to cracks and cause the bearing to fail very quickly after it starts running.

- Contamination: Tiny particles like dust and dirt are a bearing’s worst enemy. If they get inside, they act like sandpaper, constantly wearing down the raceways and rolling elements.

- Grease Degradation: For sealed bearings, the grease inside has a shelf life. In hot, humid, or overly long storage conditions, the grease can oxidize, harden, or separate. This means it loses its ability to lubricate.

- Physical Damage: Improper stacking, impacts, or vibration can create tiny dents on the bearing surfaces. These dents are often invisible but can become a source of noise and vibration later.

The Golden Rules – Universal Standards for All Bearings

No matter the type, all bearings should be stored according to these basic principles:

- Keep in Original Packaging: Never open the original package until you are ready to install the bearing. The factory packaging offers the best protection against rust and dust.

- The Right Environment:

- Humidity: Store bearings in a clean, dry area with a relative humidity below 60%.

- Temperature: Maintain a stable room temperature. Avoid extreme temperature changes and direct sunlight.

- Cleanliness: Keep them away from dust, chemicals, and corrosive gases.

- Store Horizontally: Bearings (especially medium to large ones) should be stored flat (horizontally) on a shelf. Do not store them upright (vertically) or hang them. This prevents their own weight from causing permanent deformation.

- Away from Vibration: Do not store bearings near equipment that creates vibrations, such as large motors or compressors. Constant, small vibrations can also create dents on the raceways.

Specific Care for Different Bearing Types

In addition to the general rules, different types of bearings need some special attention:

- Sealed/Shielded Bearings:

- Key Point: Pay attention to the shelf life of the grease inside.

- Tip: For long-term storage (over a year), it is recommended to rotate the bearing (in its package) a few times every 6-12 months. A simple quarter turn is enough. This helps redistribute the grease inside and prevents it from separating due to gravity.

- Large Roller Bearings:

- Key Point: They are heavy and can be easily damaged by improper placement.

- Tip: You must strictly follow the horizontal storage rule. The shelves must be strong enough to support their weight. Do not stack heavy objects on top of them. Use proper lifting equipment when moving them.

- Open Bearings:

- Key Point: They are the most sensitive to the external environment.

- Tip: It is critical to keep their original packaging and anti-rust coating intact. If the package is accidentally damaged, inspect the bearing and re-apply a rust preventive before repackaging it properly.

Pro-Tips for Smart Management

- Know the Anti-Rust Period:

The factory-applied rust preventive is not permanent. Under standard storage conditions, it typically lasts for 1 year. For stock older than this, a careful inspection is needed before use.

- Regular Inspection:

Make it a habit to regularly check the packaging of your stored bearings (e.g., every few months). Look for any damage, water spots, or oil stains (a sign that grease is separating).

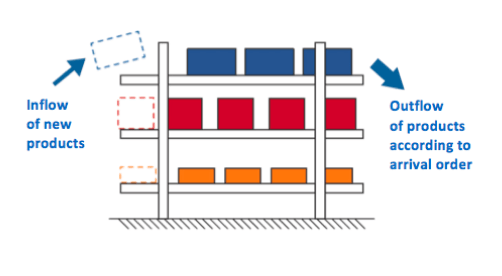

- Follow the “First-In, First-Out” (FIFO) Rule:

This is a simple inventory management principle: use the oldest stock first. This ensures your inventory is always “fresh” and helps prevent problems like expired grease or ineffective rust protection from long-term storage.

Taking Care of Your Spares is Taking Care of Your Equipment

Proper storage management is not a chore; it is a critical part of your maintenance process. It ensures that every dollar you invest is protected. It guarantees that when you need it most, your spare bearing is in 100% perfect condition, ready to protect and support your equipment.

Not finding what you need?

If you have enquiries about our product or solutionservice, please contact us via email.