Knowledge Center

The Core of High-Precision Applications: Balancing Speed, Precision, Fits, and Clearance

In the world of precision engineering, it’s easy to fall into a common trap: chasing the highest precision grade, the fastest speed, or the tightest fit, believing that extreme specifications equal peak performance. However, the result is often the opposite: increased vibration, thermal runaway, and premature system failure.

This is because limiting speed, precision, fits, and clearance are not independent variables. Instead, they form a “performance quadrilateral” where each parameter influences and constrains the others. Pulling too hard on any one corner will distort the entire shape. True expert design isn’t about pushing one parameter to its limit; it’s about understanding these interdependencies to find the unique “sweet spot” for your specific application.

Section Navigation

How to Choose the Right Bearing

- P0: The 8-Step Practical Guide to Systematic Bearing Selection

- C1: A Guide to Correctly Select a Bearing Type Based on Load, Direction, and Space

- C2: Bearing Arrangements: A Guide to Locating-Non-locating and Paired Mounting

- C3: How to Verify Bearing Size and Accurately Assess Its Lifespan

- C4: The Core of High-Precision: Balancing Speed, Precision, Fits, and Clearance

- C5: A Guide to Bearing Preload and System Rigidity Design

- C6: Choosing the Optimal Lubrication Strategy for Your Bearings

- C7: Key Design Points for Bearing-Related Components (Shaft, Housing, and Seals)

- C8: Smart Mounting and Efficient Dismounting of Bearings

Element 1: Limiting Speed – How Fast Can a Bearing Go?

Definition: The limiting speed is not an absolute red line. It is a reference speed at which a bearing can operate continuously without failing due to excessive heat generation.

Key Influencing Factors:

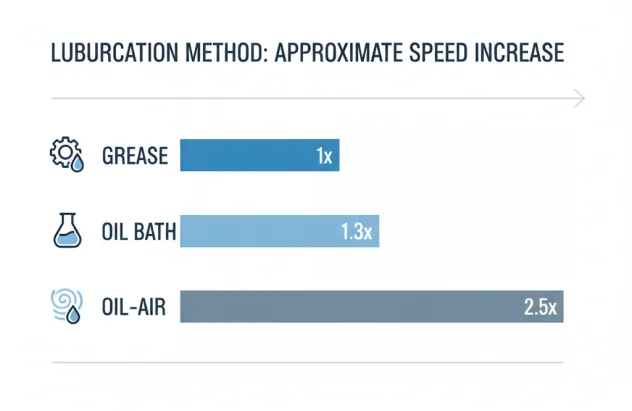

- Lubrication (The Deciding Factor): Lubrication is the lifeline of speed control. Good lubrication removes frictional heat, which is essential for high-speed operation.

- Grease Lubrication: Provides a baseline speed.

- Oil Lubrication (Oil Bath/Circulation): Can increase speed by 30%-50%.

- Oil-Air / Oil-Jet Lubrication: The ultimate solution, providing precise cooling to each rolling element. Can increase speed by 2-3 times or more.

- Bearing Type and Size: Ball bearings > Roller bearings; light series > heavy series.

- Cage Material and Design: Cages made of synthetic resin (Nylon/PEEK) are lightweight and self-lubricating, allowing for much higher speeds than steel or brass cages.

- Load and Precision: Higher loads generate more heat, reducing the permissible speed. Higher precision grades allow for smoother, more stable rotation, thus enabling higher speeds.

Element 2: Precision Grade – The Bearing’s “Accuracy”

Decoding the Standards: International standards (ISO) classify bearing precision from lowest to highest as P0 (Normal), P6, P5, P4, and P2 (High Precision).

What Does Precision Actually Mean?

- Dimensional Tolerance: Higher-grade bearings are manufactured with smaller errors in their bore, outer diameter, and width.

- Rotational Accuracy (The Core Value): This is what truly matters in precision applications. It means the bearing has less radial run-out and axial run-out. In simple terms, the shaft’s axis of rotation deviates less, resulting in a smoother, more precise motion.

When Do You Need Higher Precision?

- High-Speed Applications: To minimize vibration caused by imbalance.

- High-Positioning-Accuracy Applications: For machine tool tables or optical scanners, where rotational accuracy directly affects product quality.

- Low-Noise, Low-Vibration Applications: For precision motors or medical equipment.

Element 3: Fit – The “Marriage” of Bearing to Shaft and Housing

Purpose: To prevent the bearing rings from slipping or “creeping” relative to the shaft or housing, ensuring that loads are transferred effectively.

The Three Types of Fits:

- Interference Fit: The shaft is slightly larger than the bearing bore. It requires pressure to be installed.

- Clearance Fit: The shaft is slightly smaller than the bearing bore. It slides in easily.

- Transition Fit: In between the two; could result in either a tight or loose fit.

The Golden Rule: “Interference fit for the rotating ring, clearance fit for the stationary ring.” For example, if the inner ring rotates with the shaft, use an interference fit on the shaft. If the outer ring is stationary in the housing, use a clearance fit in the housing.

Warning: An excessive interference fit is a double-edged sword. It will “squeeze” the bearing’s inner ring, causing it to expand and drastically reduce the bearing’s internal clearance, sometimes even creating a negative clearance (preload). This is a common cause of overheating and early failure.

Element 4: Internal Clearance – The “Breathing Room”

Understanding the Concept: A bearing’s clearance is dynamic.

- Initial Clearance: The clearance of the bearing as it comes from the factory (e.g., C2-small, CN-normal, C3-large, C4-larger).

- Mounted Clearance: The Initial Clearance minus the reduction caused by the “squeeze” of an interference fit.

- Operating Clearance: The Mounted Clearance minus the reduction caused by the temperature difference during operation (the inner ring usually gets hotter and expands more than the outer ring).

Why Operating Clearance is All That Matters: The ideal operating clearance is a value that is slightly positive or slightly negative. In this state, the load is distributed most evenly across the rolling elements, and the bearing’s life, rigidity, and performance are optimized. Too much clearance reduces accuracy; too little reduces life.

The Core: The Art of Balance – Case Studies

Case 1: High-Speed Electric Spindle (Goal: High Speed + High Precision)

- Speed Requirement (Very High) → Oil-air lubrication is mandatory. Hybrid ceramic bearings are chosen to further increase speed.

- Precision Requirement (Very High) → P4 or higher precision grade is necessary.

- Clearance Selection: High speed means high heat and significant inner ring expansion. Therefore, a larger initial clearance (e.g., C3) is needed to provide “room” for this expansion. Alternatively, preload is applied to precisely control the operating clearance to a slight negative value for maximum rigidity.

- Fit Selection: A tight interference fit on the shaft is required to maintain rigidity and prevent creep.

- The Balancing Act: The engineer’s key task is to precisely calculate the sum of “clearance lost to the fit” and “clearance lost to heat.” The goal is to ensure that after starting with a larger initial clearance, the final operating clearance falls within the ideal, slightly negative range.

Case 2: General Precision Motor (Goal: Low Noise + Long Life)

- Speed Requirement (Medium-High) → Grease lubrication is sufficient, but a high-speed, low-noise grease should be used.

- Precision Requirement (High) → P6 grade provides a great balance of performance and cost.

- Clearance Selection: To minimize noise while accommodating normal heat, C3 clearance is the industry-standard choice, offering the best trade-off.

- Fit Selection: The fits should not be overly tight, as this can create internal stress, increasing friction and noise.

- The Balancing Act: This is a balance of performance versus cost. The classic combination of P6 precision + C3 clearance + appropriate fits achieves the best equilibrium between noise, life, and performance within a controlled budget.

Selection Checklist and Conclusion

| Consideration Factor | Decision Point | Related Impact On… |

| Speed (dn value) | What is the magnitude? | Lubrication method, Precision grade, Clearance |

| Positioning Accuracy | What is required? (µm) | Precision grade, Fits, Rigidity (Preload) |

| Load Type | Which ring rotates? | Choice of fit (Interference/Clearance) |

| Operating Temp. | Is there a large temp. diff? | Initial clearance selection |

Conclusion

Bearing selection in high-precision applications is never about choosing isolated parameters; it is a systematic engineering decision. Understanding the “art of balance” between speed, precision, fits, and clearance is the essential path to becoming an expert in bearing selection and designing stable, reliable, and long-lasting high-performance systems.

Not finding what you need?

If you have enquiries about our product or solutionservice, please contact us via email.