Knowledge Center

The Heart of a Bearing: A Guide to Its Specialized Materials

A bearing may look simple, but it is a masterpiece of material science. Its ability to work reliably day after day under extreme pressure and speed comes from the special materials it is made of. Like a well-organized team, each part of a bearing has a unique mission. This means each part needs a very specific set of properties from its material.

Today, let’s explore what “superpowers” these components need and how engineers choose materials to give them these powers.

Section Navigation

#1 What is a Bearing?

#2 Bearing Knowledge for Beginners

#3 Operation Guide for Bearings After Arrival

Role Determines Demand – The Mission of Bearing Components

Before we look at specific materials, let’s understand the role each component plays on the “battlefield”:

- Rings & Rolling Elements: They are the frontline soldiers. All loads are transferred through them. They withstand huge pressure on very small contact areas and roll against each other at high frequencies.

- Demands:

Extreme Hardness: To resist pressure and prevent dents.

High Wear Resistance: To last long without being worn down by rolling friction.

Excellent Fatigue Strength: To endure billions of stress cycles without cracking.

Good Dimensional Stability: To keep its exact shape and size during temperature changes and long-term use.

- Cage: It is the team’s organizer. Its job is not to carry load, but to keep the rolling elements separated in an orderly way. It guides their movement and prevents them from colliding.

- Demands:

Sufficient Strength and Toughness: To handle forces from acceleration and vibration without breaking.

Low Friction Properties: To create as little friction as possible when touching the rolling elements.

Chemical Stability: To not react with lubricants.

Lightweight (especially at high speeds): To reduce centrifugal force, noise, and heat.

- Seals & Shields: They are the loyal guards. Their duty is to protect the inside of the bearing. They keep the lubricant in and keep contaminants (dust, water) out.

- Demands:

Wear Resistance (for contact seals): The seal lip must last a long time while touching the rotating ring.

Oil and Chemical Resistance: To not be damaged by lubricants or the outside environment.

Good Elasticity: To maintain a tight seal over time.

The Right Material for the Right Job – A Review of Common Bearing Materials

Now that we understand the demands, let’s see how engineers select the perfect materials for these roles.

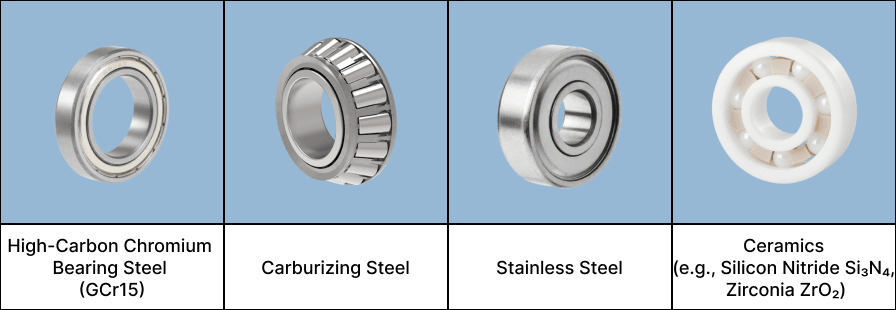

| Component | Common Materials | Characteristics & Advantages |

| Rings & Rolling Elements | High-Carbon Chromium Bearing Steel (GCr15) | This is the mainstream and classic choice. After heat treatment, it has very high hardness, excellent wear resistance, and great fatigue strength at a good cost. Most bearings you see are made of this. |

| Carburizing Steel | It has a hard surface but a tough core. This “hard on the outside, tough on the inside” structure makes it very resistant to shock loads. It’s used for heavy-duty or high-vibration applications, like in rolling mills. | |

| Stainless Steel | Its key advantage is rust prevention. It is widely used in wet or corrosive environments, such as in food processing machinery and medical equipment. Its hardness and load capacity are usually a bit lower than standard bearing steel. | |

| Ceramics (e.g., Silicon Nitride Si₃N₄, Zirconia ZrO₂) | This is a “material of the future.” It is harder, lighter, and more resistant to heat and corrosion than steel. It is also an electrical insulator. It’s the perfect choice for extreme conditions like high speeds, high temperatures, or strong corrosion, but it is more expensive. |

| Component | Common Materials | Characteristics & Advantages |

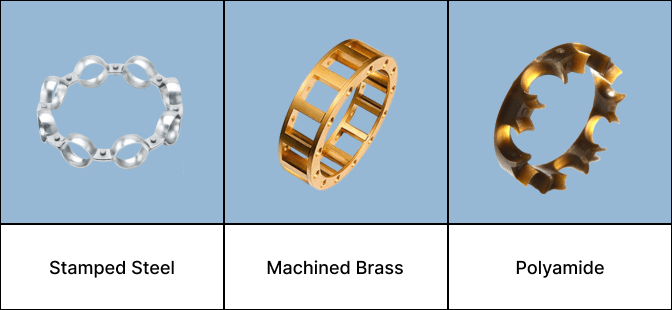

| Cage | Stamped Steel | The most common and cost-effective type of cage. It is lightweight and strong enough for most general-purpose applications. |

| Machined Brass/Bronze | It is strong, wear-resistant, and not affected by some lubricants. It is often used in medium to large bearings or in applications with higher speeds, accelerations, and vibrations. | |

| Polyamide/Nylon | It is lightweight, quiet, and has good elasticity and self-lubricating properties. It significantly reduces noise and friction during operation, making it ideal for high-speed, low-noise applications (like in premium electric motors). |

| Component | Common Materials | Characteristics & Advantages |

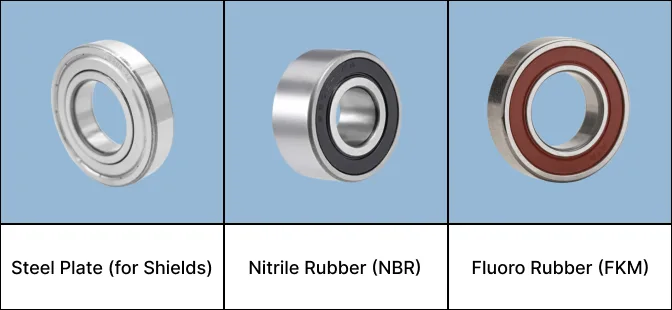

| Seals/Shields | Steel Plate (for Shields) | Used to make shields (Z/ZZ). It has a simple design and is effective at blocking large contaminant particles. Because it does not touch the inner ring, it has no effect on speed. |

| Nitrile Rubber (NBR) | This is the standard material for contact seals (RS/2RS). It has good oil resistance, wear resistance, and is cost-effective. It is suitable for most general working conditions. | |

| Fluoro Rubber (FKM) | This is an “upgraded version” of NBR. Its resistance to high temperatures and chemicals is far better than NBR’s. It’s used in more demanding environments like car engines and chemical equipment. |

No “One-Size-Fits-All” Material, Only Precise Choices

A bearing is reliable because it is a precision system built from a combination of high-performance materials. From the hard bearing steel, to the flexible nylon cage, to the oil-resistant rubber seal, each material plays a vital and irreplaceable role. Understanding these materials not only helps us appreciate bearings more, but also guides us to select the most durable and suitable product for any specific application.

Not finding what you need?

If you have enquiries about our product or solutionservice, please contact us via email.