Knowledge Center

Home / Bearings Knowledge Center / Evidence of Improper Installation: A Forensic Analysis of Indentations, Cracks, and Cage Damage

Evidence of Improper Installation: A Forensic Analysis of Indentations, Cracks, and Cage Damage

A high-quality bearing is like a well-trained athlete, full of potential. But if it gets injured during a “bad warm-up” before the competition even starts, it will never perform at its best. For a bearing, installation is its warm-up. Incorrect mounting techniques can leave a bearing with permanent “internal injuries.” These scars—indentations, cracks, and cage deformation—are the hard evidence of its premature failure. This article will take you to the “crime scene” of bearing installation to learn how to identify this evidence and catch the culprits behind it.

Section Navigation

#1 Precision, Clearance and Preload

#2 Bearing Failure Analysis Atlas

#3 Cost & Efficiency Optimization & Reliability Upgrade

The Evidence Locker – Three Classic Types of Installation Damage

Before we analyze the causes, let’s learn to recognize the three most common pieces of evidence.Indentations (Brinelling) – The “Fatal Footprints”

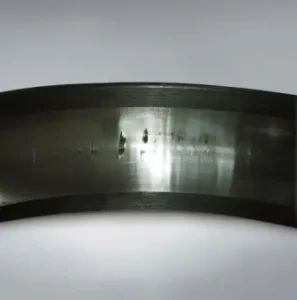

- Characteristics: A series of regular dents on the raceway that perfectly match the shape and spacing of the rolling elements (balls or rollers). These dents may be shiny or dull.

- The Damage: The material in these localized areas has been stressed beyond its elastic limit, creating a permanent plastic deformation, like pressing a marble into clay. This damage is irreversible.

- Consequences: As the bearing rotates, every time a rolling element passes over these dents, it generates vibration and noise. The dents also act as stress risers, which eventually lead to fatigue spalling.

Ring Cracking – The “Unhealable Fracture”

- Characteristics: A crack appears on the inner or outer ring. The most typical case is a straight, axial crack that runs across the entire width of the inner ring.

- The Damage: The bearing ring was subjected to stress that exceeded its material strength, causing a structural fracture.

- Consequences: The crack can propagate quickly, causing the ring to break apart, the bearing to seize, and potentially leading to catastrophic equipment failure, such as a broken shaft.

Cage Deformation – The “Twisted Skeleton”

- Characteristics: The cage is bent, fractured, or its rivets are loose or have fallen out.

- The Damage: The cage was subjected to abnormal squeezing, impact, or prying forces during installation.

- Consequences: A deformed cage will interfere with the rolling elements or rings, creating noise and heat. In severe cases, the cage can disintegrate, allowing the rolling elements to bunch up and causing the bearing to seize instantly.

Uncovering the “Methods” – Four Common Installation Errors

How is this evidence created? Here are the four most common incorrect mounting techniques.The Fatal Mistake: Striking the Wrong Ring

- The Error: Hitting the outer ring when mounting the inner ring onto a shaft, or hitting the inner ring when mounting the outer ring into a housing.

- Evidence Produced: Indentation (Brinelling).

- The Science: The mounting force is transmitted through the rolling elements from one ring to the other. At the tiny contact points, the instantaneous impact creates enormous pressure, directly pressing dents into the raceway that correspond to each rolling element. This is the single most common cause of brinelling.

Brute Force: Excessive Fits and Improper Heating

- The Error:

- Forcing a bearing onto an oversized shaft (the interference fit is too tight).

- Using a torch or open flame to heat a bearing unevenly, causing thermal stress.

- Evidence Produced: Ring Cracking.

- The Science: An excessive interference fit forces the inner ring to stretch beyond its limits, creating immense “hoop stress” that can crack it, like an overinflated balloon. Uneven heating creates massive internal thermal stresses that can also cause the ring to fracture.

Skewed Mounting: The Rushed Job

- The Error: Not keeping the bearing perfectly square to the shaft or housing during press-fitting, allowing it to go in at an angle.

- Evidence Produced: Cage Deformation, Raceway Scratching.

- The Science: A tilted bearing gets jammed. The mounting force becomes concentrated on the cage or a few rolling elements instead of being evenly distributed across the ring face. This can easily bend, scrape, or even crush the cage.

The Dirty Environment: The Unseen Enemy

- The Error: Working in a dusty environment, or failing to clean metal shavings, burrs, and dirt from the shaft, housing, and tools before mounting.

- Evidence Produced: Indentations (usually randomly spaced).

- The Science: These hard particles get trapped between the rolling elements and raceways. Like a pebble in your shoe, they get pressed into the raceway, creating random, irregular dents that become sources of early wear.

The Field Investigation: A Diagnostic Guide

| Observed Evidence | Inferred “Method” (Root Cause) | Practical Investigation Tips |

| Regularly spaced dents on the raceway, matching the rolling elements. | Mounting force transmitted through rolling elements (striking the wrong ring). | Review the company’s installation procedures and tools. Ask the operator if a hammer or an improper sleeve was used. This is a textbook mounting error. |

| Inner ring is cracked straight across its width. | Excessive interference fit or improper heating. | 1. Measure! Use micrometers and bore gauges to accurately measure the shaft and housing dimensions. Compare them to the drawing tolerances. 2. Ask about the heating method. Was an uncontrolled heating device used? |

| Cage is visibly bent, broken, or rivets are loose. | Skewed (tilted) mounting or prying on the cage during installation. | Check for a proper lead-in chamfer on the shaft and housing. Check if the mounting tool (e.g., a sleeve) has a flat face that makes even contact with the entire ring face. |

| Random, irregular dents on the raceway. | Contamination during installation. | Inspect the cleanliness of the work area. Check the residual grease for visible contaminants. |

The Prevention Playbook: Golden Rules of Professional Installation

Installation damage is 100% preventable. Follow these golden rules:Rule 1: Apply Force to the Correct Ring.

- When mounting a bearing onto a shaft, apply force only to the inner ring.

- When mounting a bearing into a housing, apply force only to the outer ring.

- The Core Principle: Never transmit mounting force through the rolling elements!

Rule 2: Use the Right Tools for the Job.

- Cold Mounting: Use a professional bearing fitting tool kit (with impact sleeves that fit the ring faces perfectly) and a press. Say goodbye to hammers!

- Hot Mounting: Use a temperature-controlled induction heater to heat the bearing evenly to around 110°C (230°F). Say goodbye to torches and oil baths!

- Dismounting: Use a professional bearing puller.

Rule 3: Cleanliness is Paramount.

- Ensure the bearing, shaft, housing, tools, and your hands are perfectly clean.

Rule 4: Alignment and Patience.

- Before applying force, make sure the bearing is perfectly square and aligned. Apply pressure slowly and steadily. If you feel unusual resistance, stop and investigate.

Reading the Past to Predict the Future

Indentations, cracks, and cage deformation in a bearing—these seemingly severe “internal injuries”—almost always originate from a moment’s carelessness or a misplaced hammer blow during installation. Unlike other failure modes that develop slowly over time, installation damage seals a bearing’s fate from the very first second it begins to rotate. Therefore, there is no “repair” for this type of damage; the only weapon is “prevention.” This involves more than just buying an expensive heater or puller. It’s about establishing a standardized and enforceable mounting procedure:- Before mounting, ensure everything is clean and all dimensions are verified.

- During mounting, use the right tool to apply force to the right ring.

- After mounting, perform an initial test run and listen for any abnormalities.

Not finding what you need?

Contact Sales

If you have enquiries about our product or solutionservice, please contact us via email.