Bearings are critical components in almost every type of machinery, from small electric motors to large industrial equipment. Their primary role is to reduce friction, support loads, and ensure smooth motion. However, bearings do not last forever. Over time, wear, contamination, misalignment, or inadequate lubrication can lead to failure. Recognizing signs of bearing replacement early is essential to prevent unexpected breakdowns, production losses, and expensive repairs.

Replacing a bearing at the right time not only protects surrounding components such as shafts and housings but also improves machine reliability and operational safety. This guide explains the most common warning signs of bearing failure, why they occur, and how proper maintenance can significantly extend bearing service life.

Why Timely Bearing Replacement Matters

Delaying bearing replacement can have serious consequences. A failing bearing often causes increased vibration, excessive heat, and abnormal noise, which can quickly escalate into complete machine failure. In industrial settings, this may result in unplanned downtime, damaged equipment, and safety risks for operators.

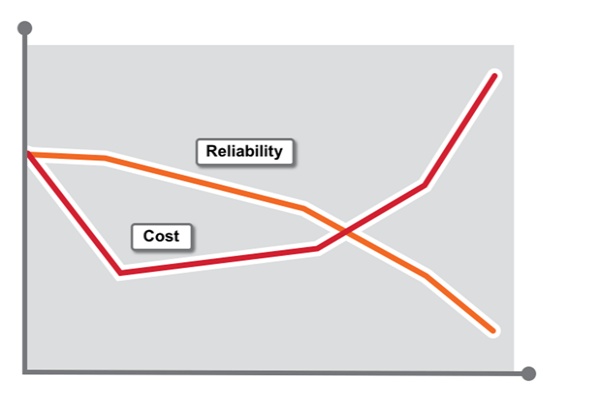

Timely bearing replacement reduces long-term maintenance costs by preventing secondary damage. It also helps maintain consistent machine performance and efficiency, especially in continuous or high-load applications. Understanding early bearing replacement signs allows maintenance teams to take corrective action before failure occurs.

SDTFL Note: Don’t risk your production line with substandard components. As a direct factory manufacturer, SDTFL Bearings provides high-durability solutions designed to withstand heavy loads and reduce replacement frequency. Contact our engineering team for a reliability assessment today.

Common Early Bearing Replacement Signs

One of the most noticeable bearing replacement signs is unusual noise. Grinding, squealing, clicking, or rumbling sounds often indicate internal wear, surface damage, or lubrication failure. These noises usually worsen as the bearing condition deteriorates.

Excessive vibration is another critical indicator. Bearings that are worn, misaligned, or damaged tend to produce irregular vibration patterns. Monitoring vibration levels can help detect problems early, even before audible noise becomes apparent.

Abnormal temperature rise is also a warning sign. Bearings generate heat during normal operation, but excessive heat often signals lubrication issues, excessive load, or internal damage. Overheating accelerates wear and significantly shortens bearing life.

Need a Quieter Operation? Low-noise and low-vibration bearings are our specialty. Browse our Deep Groove Ball Bearings Catalog to find precision components that run smoother and longer.

Visual and Physical Indicators of Bearing Failure

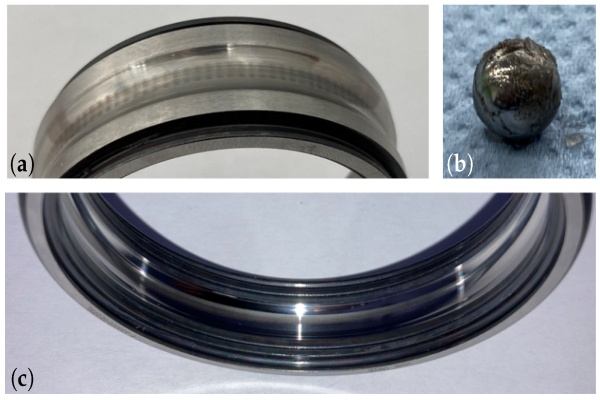

In some cases, bearing replacement signs can be identified through visual inspection. Discoloration of bearing components, especially blue or darkened areas, often indicates overheating. Cracks, pitting, or flaking on raceways and rolling elements are clear signs of fatigue damage.

Lubricant condition can also reveal bearing health. Grease that appears discolored, hardened, or contaminated with metal particles suggests internal wear or contamination. Leakage of lubricant may indicate seal failure, which can lead to rapid bearing deterioration.

Performance-Related Warning Signs

Changes in machine performance often point to bearing issues. Reduced rotational accuracy, increased friction, or decreased efficiency may be caused by bearing wear. In precision equipment, even small bearing defects can lead to noticeable performance degradation.

In severe cases, shaft movement or looseness may occur due to bearing clearance increase or cage failure. These symptoms typically indicate advanced damage and require immediate bearing replacement to avoid catastrophic failure.

Main Causes Behind Bearing Failure

Understanding the root causes of bearing failure helps identify bearing replacement signs more accurately. Inadequate or improper lubrication is one of the most common causes. Without sufficient lubrication, metal-to-metal contact occurs, leading to rapid wear and overheating.

Contamination from dust, moisture, or chemicals can also damage bearings by causing abrasive wear and corrosion. Misalignment and improper mounting introduce uneven load distribution, accelerating fatigue. Excessive loads or operating beyond speed limits further reduce bearing life.

Bearing Replacement Signs Summary Table

Key Bearing Replacement Signs and Their Likely Causes

| Warning Sign | Likely Cause |

| Unusual noise | Surface damage, poor lubrication |

| Excessive vibration | Wear, misalignment, imbalance |

| Overheating | Lubrication failure, overload |

| Discolored components | Excessive heat or friction |

| Metal particles in grease | Internal wear or fatigue |

| Reduced machine performance | Increased friction or clearance |

| Shaft looseness | Advanced bearing damage |

Recommended Replacement Bearings by Application

If you have identified any of the signs above, choosing the right replacement is crucial. Based on common machinery needs, we recommend the following SDTFL product series:

- For Electric Motors & Fans (Low Noise/High Speed):

- Deep Groove Ball Bearings (6000, 6200, 6300 Series) – Sealed and shielded options available for maintenance-free operation.

- For Conveyor Systems & Heavy Loads:

- Spherical Roller Bearings (22200, 22300 Series) – Self-aligning capabilities to handle shaft deflection and heavy vibration.

- For Automotive & Gearboxes:

- Tapered Roller Bearings – Designed to manage combined radial and axial loads efficiently.

- For Agricultural & Industrial Mounting:

- Pillow Block & Insert Bearings (UCP, UCF Series) – Easy-to-install units perfect for quick replacements in dirty environments.

Maintenance Tips to Extend Bearing Life

Preventive maintenance is the most effective way to delay bearing replacement. Proper lubrication is essential. Using the correct lubricant type and maintaining appropriate lubrication intervals significantly reduces wear and heat generation.

Keeping bearings clean and protected from contaminants is equally important. Seals and shields should be inspected regularly, and damaged seals should be replaced promptly. Proper storage and handling of bearings before installation also prevent contamination-related failures.

Correct installation practices are critical. Bearings should be mounted using appropriate tools and methods to avoid damage to raceways or rolling elements. Alignment should always be verified to ensure even load distribution during operation.

Condition Monitoring and Predictive Maintenance

Modern maintenance strategies rely on condition monitoring to detect signs of bearing replacement early. Vibration analysis, temperature monitoring, and acoustic measurements provide valuable data on bearing health. These techniques help identify issues before they lead to failure.

Predictive maintenance allows maintenance teams to schedule bearing replacement during planned downtime rather than reacting to unexpected breakdowns. This approach improves equipment availability and reduces overall maintenance costs.

When Immediate Bearing Replacement Is Necessary

Some bearing replacement signs indicate that immediate action is required. Severe noise, rapid temperature increase, visible cracking, or complete lubrication loss are strong indicators that the bearing is near failure. Continuing operation under these conditions can cause extensive damage to the machine.

In such cases, the bearing should be replaced as soon as possible, and the root cause of failure should be addressed to prevent recurrence. Simply replacing the bearing without correcting the underlying issues may result in repeated failures.

Recognizing bearing replacement signs early is essential for maintaining reliable and efficient machinery. Noise, vibration, heat, visual damage, and performance changes all provide valuable clues about bearing condition. Timely replacement, combined with proper maintenance practices, helps prevent costly downtime, extend equipment life, and improve operational safety.

By understanding warning signs and implementing proactive maintenance strategies, organizations can significantly reduce bearing-related failures and ensure smooth, uninterrupted operation.

Urgent Replacement Needs? We keep a vast stock of standard sizes ready for immediate shipment to minimize your downtime. Click here to chat with us or email us for express dispatch options.

Secure Your Machinery’s Future with SDTFL Bearings

At SDTFL Bearings, we understand that identifying bearing replacement signs is only the first step; choosing a reliable replacement is the solution. We are more than just a supplier; we are a dedicated factory manufacturer committed to producing high-performance bearings that withstand the toughest industrial demands. Whether you need standard replacements or custom solutions, our team ensures you get factory-direct quality at competitive prices.

Don’t wait for a catastrophic failure to halt your operations. Take action today to secure your inventory and protect your equipment.

- Start Your Order: Click here to visit our Product Catalog

- Get a Fast Quote: Email us at info@sdtflbearing.com

- Talk to an Expert: Call us directly at +86 15806631151

Let SDTFL Bearings be the power behind your smooth operations. Contact Us now!

Frequently Asked Questions (FAQ)

How often should bearings be replaced?

There is no fixed replacement interval for bearings. Replacement depends on operating conditions, load, speed, lubrication, and environment. Bearings should be replaced when clear bearing replacement signs appear or when condition monitoring indicates deterioration.

Can a noisy bearing still be used?

A noisy bearing usually indicates internal damage or lubrication problems. Continued operation can lead to rapid failure and damage to other components. It is recommended to inspect and replace noisy bearings promptly.

What is the most common cause of bearing failure?

Inadequate lubrication is the most common cause of bearing failure, followed by contamination and misalignment. Proper lubrication and sealing significantly extend bearing life.

Does overheating always mean the bearing is damaged?

Not always, but persistent overheating is a serious warning sign. It may indicate lubrication issues, excessive load, or misalignment. If overheating continues, bearing replacement is often necessary.

Can condition monitoring prevent bearing failure?

Yes, condition monitoring techniques, such as vibration and temperature analysis, help detect early signs of bearing replacement and enable planned maintenance before failure occurs.