Is It Normal for Motor Bearings to Make Noise?

Yes — a certain level of bearing noise is completely normal during motor operation.

What matters is whether the noise is stable and consistent, or a warning sign of failure.

TFL summarizes three key indicators of normal bearing sound:

- Stable and uniform tone – no sudden metallic clicks or squeaks.

- Sound changes with speed – noise increases proportionally with RPM.

- No irregular frequency spikes – no cyclic knocks or vibration bursts.

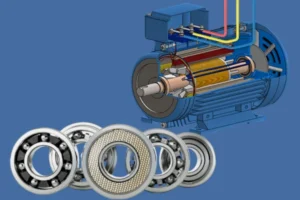

Do “Silent” Bearings Exist? Uncovering Inherent Bearing Sounds

Many engineers often ask, “How can bearing noise be completely eliminated?” The answer is: it’s impossible to eliminate entirely. Bearings will inevitably produce some inherent sounds during normal operation. These sounds are not indicators of malfunction but rather natural byproducts of their internal movements.

- Slight Collisions Between Rolling Elements and Raceways: In the unloaded zone, rolling elements, after leaving the loaded zone, still possess a certain linear velocity and centrifugal force, leading to slight radial or axial collisions with the raceways. This collision sound is particularly noticeable when residual clearance exists.

- Interaction Between Rolling Elements and Cage: The cage guides the rolling elements, and axial, radial, and even circumferential collisions can occur between them. For instance, rolling elements actively push the cage in the loaded zone, or the cage pushes the rolling elements in the unloaded zone, as well as radial collisions of rolling elements with the cage due to centrifugal force.

- Lubricant Churning Sound: The lubricant inside the bearing is churned as the rolling elements move, which also generates a continuous sound.

- Sliding Friction as Rolling Elements Enter and Exit the Loaded Zone: Rolling elements experience a certain degree of sliding friction with the raceway when entering and exiting the loaded zone.

- Other Internal Movements: Bearings with seals may also produce slight noise due to the friction of their lips against the bearing rings.

Therefore, all normally operating rolling bearings will inevitably produce these inherent “normal noises.”

Characteristics of Normal Motor Bearing Sound: Stable, Uniform, No Abnormalities

Based on the analysis above, the primary characteristic of normal noise produced by a qualified bearing is that it should be stable and uniform. This means the volume and frequency of the noise should not fluctuate drastically but remain at a relatively steady level.

When a motor operates at a constant speed, the various internal movements of the bearing (such as rolling element friction, collisions, grease churning, seal friction) should also be in a stable state. Consequently, the bearing noise produced should be stable and uniform. Of course, “stable and uniform” does not refer to a constant single tone but rather a stable composite of small-cycle collision sounds and some continuous friction sounds.

In practical assessment, in addition to stability and uniformity, we must also consider a crucial factor: no abnormal frequencies. This means there should be no sharp squealing, periodic knocking, or obvious cyclical variations, which are often signs of an impending or existing bearing failure. For example, some interference-induced noises might also be stable and uniform, but their perceived frequency would differ significantly from the expected normal frequency of a bearing.

| Sound Feature | Normal Bearing Sound (Inherent Noise) | Abnormal Bearing Sound (Fault Warning) | Potential Cause |

| Volume | Low, consistent, increases smoothly with speed. | Suddenly loud, sharp, or intermittent. | Early wear, poor lubrication, excessive preload. |

| Pitch/Frequency | Stable, proportional to speed, no specific “foreign frequency.” | Presence of a sharp squeal, a deep “rumbling” sound, or periodic “clacking” or “thumping” noises. | Raceway/roller spalling, loose fit, contaminated grease, cage damage. |

| Uniformity | Uniform, continuous, smooth “acoustic envelope.” | Intermittent, irregular, such as extra “squeaking” upon startup or shutdown. | Current corrosion (electrical erosion), foreign debris ingress, installation damage. |

Expert Reference: TFL’s bearing design adheres to ISO 15242 standards for vibration and noise measurement and evaluation. If the noise emitted by your equipment’s bearing frequency is no longer synchronous with the rotational speed, or a sharp, singular frequency tone appears, immediate inspection is required.

Through efficient, self-owned factory operations, we can offer prices more competitive than international giants (e.g., FAG/SKF) while guaranteeing P5 (ABEC-5) or even P4 (ABEC-7) precision. We also achieve a shorter lead time on custom orders (standard items are kept in stock, custom order cycles are reduced by 20%).

TFL Bearings: Your Expert in Customized High-Performance Bearings

Whether you require standard bearing models or customized solutions for specific operating conditions, TFL Bearings can meet your needs.

We are committed to providing high-quality, reliable bearing products and excellent service to B2B customers worldwide. Our professional technical team can offer expert selection advice and customized designs based on your specific application scenarios.

Contact our technical team now for a professional quote and customized proposal:

Click the pop-up window on the sidebar to communicate with our experts in real-time!

Send your inquiry to: info@sdtflbearing.com

Click to browse our catalog of various types and various sizes of bearings and review our success stories.