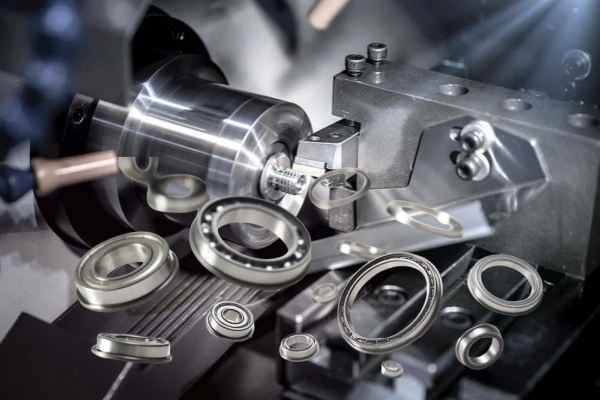

Are you grappling with high friction, frequent breakdowns, or the difficulty of sourcing non-standard bearing sizes in your equipment?

TFL Bearings, a leading Chinese bearing manufacturer, offers comprehensive and customizable high-precision bearing solutions. If your CNC machinery, robotics, or automation systems require tight tolerances and zero vibration, TFL Bearings are designed for you.

Key Advantages of TFL High Precision Bearings:

- Extensive Coverage: We supply a wide range of standard and non-standard size ball bearings, roller bearings, thrust bearings, and more, meeting diverse application needs.

- Superior Performance: Our bearings meet or exceed ISO standards for precision, guaranteeing low noise, minimal vibration, and extended service life.

- Customization Services: We provide personalized custom manufacturing for specific operating conditions and design requirements, perfectly matching your equipment.

- Cost-Effectiveness: While ensuring high quality, we offer competitive pricing and ample stock, optimizing your procurement efficiency.

- Expert Support: Our team of experienced engineers provides technical consultation and solutions, ensuring you select the most suitable bearings.

Why Your High-End Equipment Requires “High Precision” Bearings

The critical mistake many purchasers make is selecting standard tolerance bearings (such as ISO P0/P6 grade) for demanding applications like CNC machine tool spindles, precision instruments, or aerospace components. In these high-demand scenarios, minor errors are amplified into major issues by operating speed and load.

Key Difference: Precision Grade vs. Performance Impact

| Precision Grade | Radial Runout (TFL P4 Grade) | Typical Application Scenario | Resulting Pain Point Solved |

| ISO P4 (ABEC 7) | ≤0.005mm | High-speed spindles, precision gearboxes, aerospace equipment | Increases equipment operating speed by 30%, reduces vibration by 25% |

| ISO P6 (ABEC 3) | ≤0.010mm | General machinery, motors | Insufficient precision, leading to significant thermal drift and excessive spindle runout |

TFL’s High Precision Bearings

Specific Bearing Types and Specification Examples

We understand you need concrete products to solve real-world problems. Below are the high precision product lines TFL offers to B2B customers, and the pain points they address:

Ultra-Precision Angular Contact Ball Bearings (7000/7900 Series):

- Pain Point Solved: The need for high rigidity and speed in CNC machine tool spindles.

- TFL Advantage: We provide matched bearing sets with precise preload (Light/Medium/Heavy). For example, model 7018C P4 achieves a maximum rotational speed of 25,000 RPM and maintains a radial runout precision of 0.003mm even at an extreme operating temperature of 100℃.

Double Row Cylindrical Roller Bearings (NN30 Series):

- Pain Point Solved: High load capacity and stiffness requirements for industrial pumps and large gearboxes.

- TFL Advantage: Offers separable inner and outer rings for easier installation. Model NN3020K P4 has a basic dynamic load rating (C) of 120 kN, capable of stably enduring extreme radial loads.

Customization Services: From Design to Delivery in Just 4 Weeks

Customizing non-standard bearings often means lengthy lead times and high tooling costs. TFL’s independent website business is designed to solve this very problem.

We offer the following customization services, aimed at achieving fast, cost-effective production of non-standard parts:

- Non-Standard Dimensions and Tolerances: For old equipment upgrades or specific design needs, we can rapidly adjust bore, outer diameter, and width, with minimum tolerances controlled at 0.001mm.

- Special Materials: For corrosive or high-heat environments, we offer ceramic balls (Hybrid Bearings) or PEEK/Phenolic resin cages, extending bearing life in harsh conditions by 200%.

- Lubrication Solutions: Pre-fill with specific brands of precision grease, such as the Krytox series for high-speed operation, based on the customer’s operating conditions.

Equivalent Performance, Superior Pricing

While ensuring P4/P2 grade performance and stability, TFL’s optimized supply chain and manufacturing costs enable significant cost advantages for our customers:

- Cost Savings: Compared to procuring bearings of equivalent precision and performance in Europe or Japan, choosing TFL can help your project save 15% to 25% on procurement costs.

- Inventory and Lead Time: We maintain an ample inventory of semi-finished goods for common models, allowing lead times for non-customized items to be shortened to 1-2 weeks.

Quality Assurance Exceeding Industry Standards

As a professional Chinese factory, TFL’s quality management system goes beyond just documentation. We understand that B2B customers prioritize quality far above price.

- Benchmarking Leaders: We adhere to ISO 199/200 bearing tolerance standards and guarantee that TFL’s P4/P2 grade products meet or exceed the performance of comparable products from top-tier brands like FAG (Schaeffler) and SKF in the critical metric of “Bearing Vibration and Noise” (ISO 15242). Every batch of high precision bearings comes with a detailed Vibration Grade V3/V4 test report.

- Traceability: Every product batch has complete raw material reports and processing flow records, ensuring quality traceability.

Next Steps: Customize Your Exclusive High Precision Bearings

Don’t let lower-quality bearings limit the performance ceiling of your equipment. Choose TFL Bearings for a solution that delivers high performance, high reliability, and high-cost efficiency.

Act Now!

- Consultation Request: Immediately send your bearing model or technical drawings to our inquiry email at info@sdtflbearing.com. Our engineers will provide preliminary selection and quotation within 12 hours.

- Visit Our Independent Site: Browse the “Product Center” on the TFL Bearings independent website to view the detailed technical parameters of our P4/P2 grade Angular Contact Ball Bearings and Cylindrical Roller Bearings.

- +86 15806631151: Contact TFL Bearings today to request a free quotation or discuss your custom requirements.

- Get a quick quote? Submit your requirements or click the pop-up window on the sidebar to consult one-on-one with our engineering team, and we will provide a detailed quotation within 24 hours.

FAQ

What makes TFL’s high precision bearings different from standard bearings?

TFL’s high precision bearings are made to meet strict P5 and P4 standards. These bearings have tighter size limits and smoother surfaces. They work better in hard jobs. Customers see less shaking and the bearings last longer.

Can TFL bearings handle extreme environments?

Yes. TFL makes bearings for tough places. The company uses strong materials like ceramic and stainless steel. These bearings can handle heat, rust, and heavy weight. Many industries trust TFL to work well in hard conditions.

How does TFL ensure consistent quality?

TFL uses advanced machines and careful checks. Skilled workers look at each bearing during every step. The company follows world rules and has certifications like ISO9001-2015. Customers always get products that meet high standards.

Are custom bearing solutions available from TFL?

TFL gives custom solutions for special needs. The team helps customers pick the right materials, sizes, and features. Customers get bearings made just for their machines or industries.