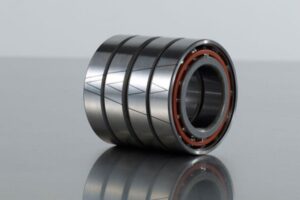

Precision angular contact bearings help high speed spindle bearings. They control contact points and stop fatigue failure. Engineers like these bearings because they keep spindle accuracy and reliability.

- Careful control of shape details, like rolling element size and raceway groove curve, lowers the chance of failure.

- Using stronger materials with better fatigue strength also lowers bearing mistakes.

Knowing these features helps technical workers get the best spindle performance.

Key Takeaways

- Precision angular contact bearings help spindles stay accurate and work well. They control where parts touch and help stop wear.

- Picking the right contact angle and preload makes bearings stiffer. This lowers shaking and helps spindles carry heavy things easily.

- High ABEC grades and strong materials make bearings faster and last longer. They also help bearings handle heat in fast, precise machines.

- Single row bearings are good for high speed and light loads. Double row bearings are stronger and steadier for heavy-duty jobs.

- Installing, oiling, and checking bearings often helps them last longer. This keeps spindles working smoothly and accurately.

Precision in Spindle Bearings

What Is Precision?

Precision in spindle ball bearings means making them very carefully. The size, smoothness, and shape inside the bearing must be exact. These things help the bearing match its design closely. Groups like ABMA set rules for how precise bearings should be. They use ABEC numbers to show how tight the rules are. A higher ABEC number means the bearing is made with more care. High precision spindle ball bearings keep the balls moving in the right path. They also keep the space inside even. This is very important for machine tool spindles. Even a tiny mistake can hurt how well the spindle works.

Note: Precision ball bearings must follow strict rules. This helps them guide parts accurately in fast machines.

Some important rules for spindle bearing precision are:

- ISO 281:2007 helps figure out how long a bearing will last.

- Preload and clearance make the bearing stiffer or let it handle heat changes.

- Good lubrication stops too much rubbing and damage.

- Knowing the right load and speed helps the bearing work well.

- Picking the right grade, contact angle, and fit stops early failure.

Fit types help keep bearings precise:

- Clearance fit is easy to put together but can shake and lose accuracy.

- Interference fit makes the bearing stiff but is harder to assemble.

- Transition fit is a mix of both and is easier to use.

- The material and how it grows with heat matter for keeping precision.

Why Precision Matters

Precision affects how well spindle ball bearings work in fast spindles. When makers use high precision bearings, they stop the spindle from moving the wrong way. This wrong movement is called runout. Even a little runout can make parts look bad or not fit right. It can also wear out tools faster or break them.

Bearings with ABEC 5 or higher usually have runout less than 0.00005 inches. This keeps the spindle spinning smoothly and makes good parts. Studies show that mistakes in bearings can make machines less accurate. If the spindle is not balanced or the bearing is not smooth, the part can have errors. High precision bearings help avoid these problems and make better parts.

If you use low-precision bearings in fast spindles, you get many problems. These bearings are not hard enough or made for tough jobs. They get damaged faster and do not last long. They can also have bad lubrication, dirt inside, and get tired on the surface. They may get too hot or break apart. But angular contact bearings made for high precision use special materials and better oil. They can handle fast speeds and high pressure.

Tip: Always pick spindle ball bearings with the best precision for your job. This helps the spindle stay accurate and last longer in fast machines.

Angular Contact Bearings Design

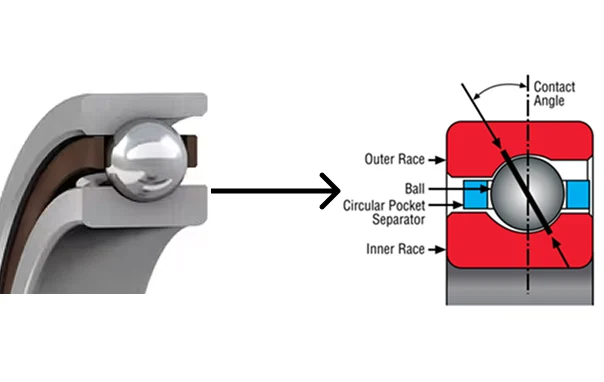

Contact Angles

Contact angle is very important for how these bearings work. The contact angle is the space between where the ball touches the raceways and a line that is straight up and down from the bearing. Engineers pick different contact angles to get the right mix of speed, strength, and how much weight the bearing can hold.

The table below shows how different contact angles change how much weight the bearing can carry and how stiff it is:

| Contact Angle | Bearing Type | Axial Load Capacity | Rigidity / Application Notes |

|---|---|---|---|

| 15° | Single-row angular contact | Lower axial load capacity | Good for high speed and accuracy |

| 25° | Single-row angular contact | Higher axial load capacity | Stiffer than 15° |

| 25° | Double-row angular contact | Medium axial load capacity | Makes the bearing setup more stiff |

| 30° | Double-row angular contact | Higher axial load capacity | Stiffer than 25° |

Bearings with a 15° contact angle are best for fast machines that need to be very accurate and have little friction. Bearings with 25° or 30° contact angles can hold more weight and are stiffer. These are better for tough jobs that need both speed and strength.

Note: Picking the right contact angle helps the spindle hold the right weight and stay accurate while working.

Materials and Grades

The kind of material and grade used changes how well the bearing works and how long it lasts. Makers often use strong steels like AISI 52100 or special ceramics for the balls. These materials help the bearing last longer and keep its shape, which is needed for fast spindles.

ABEC grades show how close the bearing is made to the right size. Higher ABEC grades, like ABEC 7 or 9, mean the bearing is made with more care. These grades make the bearing run smoother, with less rubbing and better balance. Bearings with higher ABEC grades can spin faster, make less heat, and last longer. But ABEC grades do not tell you about the material, oil, or where the bearing is used, so engineers must think about everything when picking a bearing.

- ABEC grades show how carefully the bearing is made; higher numbers (ABEC 7 or 9) mean tighter rules.

- Tighter rules make the bearing run smoother, with less rubbing and better balance, which is important for fast spindles.

- Higher ABEC grades let bearings spin faster, make less heat, and last longer.

- ABEC grades do not include things like material strength, how hard it is to break, oil, or where the bearing is used, but these things also matter.

- Picking the best bearing means thinking about ABEC grade, what the job needs, and how much it costs.

Bearings made from strong materials and with high ABEC grades give the accuracy and trust needed for fast spindles.

Preload and Tolerances

Preload is the force put inside the bearing when it is put together. This force takes away any extra space and makes the bearing stiffer. The right preload lowers shaking and noise, which is very important for fast spindles.

- Preload puts the shaft in the right spot, which lowers mistakes and makes spinning more accurate.

- It makes the bearing stiffer, so it does not bend or move out of place when loaded.

- Preload stops noise from shaking and echoing.

- It keeps the balls from sliding or spinning wrong, which can make noise and shaking.

- Bearings with preload are 2 to 3 times stiffer than those without, which helps stop shaking.

Tolerance classes, like ABEC 7 or 9, make the bearing work better by lowering extra space and making spinning more accurate. Tighter rules help spread weight better and lower mistakes, which is very important for these bearings in fast spindles. Studies show that how the bearing is put together and heat can change the space inside and the contact angle, which changes how stiff and steady the spindle is. Engineers must control preload and tolerances to keep the bearing working well and lasting longer.

Tip: Using systems that change preload can help spindles work better. They use more preload at slow speeds for strength and less at fast speeds to lower heat and make the bearing last longer.

Bearings with the right preload and tolerance class give the strength, accuracy, and long life needed for advanced spindles. These choices help the bearings hold more weight, lower shaking, and stay accurate even at very fast speeds.

Types and Arrangements

Single Row vs. Double Row

Engineers pick single row or double row spindle ball bearings based on what the machine needs. Single row angular contact bearings can only hold axial load from one side. They are simple and easy to put in. These bearings work well for fast spindles with light loads. Double row bearings have two rows of balls. They can hold both radial and high axial loads from both sides. This makes them stronger and more stable. Double row bearings are good for heavy machines like milling machines or lathes.

| Aspect | Single Row Angular Contact Bearings | Double Row Angular Contact Bearings |

|---|---|---|

| Load Capacity | Axial load in one direction; for light/medium loads | Axial load in both directions; higher load capacity |

| Rigidity | Good, but may deform under high loads | High rigidity and stability |

| Speed Suitability | Excellent for high-speed spindles | Better for heavy-duty, lower-speed spindles |

| Installation | Simple, less space needed | More complex, needs more space |

| Durability | Best for shorter cycles and lighter loads | Ideal for long life and high reliability |

Double row bearings split the load between both rows. This helps them last longer and shake less. Most high-speed spindle ball bearings start at about 12mm wide. Some can spin up to 80,000 rpm.

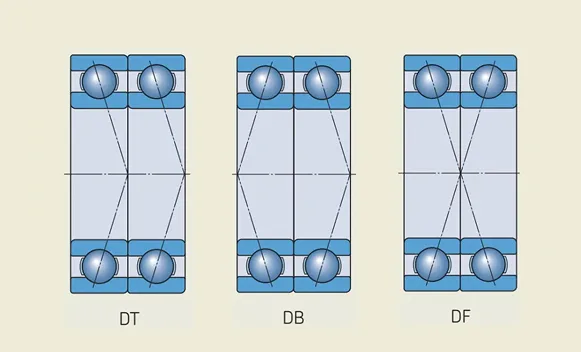

Matched Pairs

Matched pairs of angular contact bearings help spindles be more accurate and hold heavy axial loads. Engineers set up these pairs in three main ways:

- Back-to-back (DB): This setup holds radial and axial loads from both sides. It is very stiff and can handle twisting forces. It is best for spindles that get pushed hard.

- Face-to-face (DF): This setup also holds loads from both sides. It lets the spindle move a little if needed. It is good when the spindle might shift during use.

- Tandem (DT): Tandem pairs hold heavy axial load from one side. They share the load, which helps when force comes from just one direction.

| Arrangement | Load Support Direction | Stiffness and Rigidity | Moment Load Support | Misalignment Tolerance |

|---|---|---|---|---|

| Back-to-back (DB) | Both directions | Maximum rigidity | High | Low |

| Face-to-face (DF) | Both directions | Lower than DB | Lower | High |

| Tandem (DT) | One direction | Load sharing | None | N/A |

Sealed vs. Open

Spindle ball bearings can be sealed or open. Open bearings let the spindle spin fastest and have the least friction. They need oil often and work best where it is clean. Sealed bearings keep out dust and water. They keep grease inside and need less care. But seals make more friction, so speed is lower.

| Feature | Open Bearings | Sealed Bearings |

|---|---|---|

| Contaminant Protection | Low | High |

| Lubrication Retention | None | Excellent |

| Friction & Torque | Lowest | Slightly higher |

| Maintenance Needs | High | Minimal |

| Typical Applications | Clean, high-speed spindles | Dirty or hard-to-service environments |

Tip: Pick sealed bearings for spindles in dirty places or where it is hard to do repairs. Use open bearings for the fastest speed and easy oiling.

Benefits for High-Speed Spindles

Speed and Stability

Super precision angular contact ball bearings help spindles spin very fast. They keep the spindle steady while it moves quickly. These bearings use strong materials and special oil to lower heat and rubbing. Engineers pick them when machines need to go fast and run smoothly. The table below shows how fast each bearing series can go:

| Bearing Series | Shaft Max ID (mm) | Max Speed Steel (RPM) | Max Speed Ceramic (RPM) | Load Characteristics |

|---|---|---|---|---|

| KH Series | 70 | 135,000 | 168,750 | Fastest speeds, light loads |

| S Series | 120 | 195,000 | 243,750 | Standard series |

| SM Series | 120 | 230,000 | 287,500 | Faster speeds, medium loads |

Super precision angular contact ball bearings can hold weight from the side and from the end. This helps spindles move smoothly at high speed. For example, the NACHI BNH014TU/GLP4 can spin up to 19,000 RPM with oil. Small spindles can reach up to 180,000 RPM. These bearings keep shaking and noise low, which is important for steady work.

Rigidity and Accuracy

Rigidity is needed for spindles to stay accurate. Super precision angular contact ball bearings use a special angle and preload to make them stiffer. This stops the spindle from bending and keeps it cutting right. The table below shows how stiffness helps machines be more accurate:

| Factor/Aspect | Effect on Spindle Machining Accuracy |

|---|---|

| Bearing Stiffness (Rigidity) | Higher stiffness leads to better precision. |

| Preload on Spindle Bearing | Sets initial stiffness; wear reduces stiffness and accuracy. |

| Bearing Wear | Reduces preload and stiffness; restoring preload maintains accuracy. |

| Bearing Configuration | Optimal structure improves stiffness and accuracy. |

| Vibration and Dynamic Behavior | Stiffness influences vibration, affecting machining precision. |

Super precision angular contact ball bearings lower shaking and stop heat from changing their shape. Putting them back-to-back makes them even stiffer and lets them hold weight from both sides. Preload helps stop bending and keeps the spindle steady, even with heavy loads. This makes sure the machine cuts very accurately.

Note: Adjusting preload often and taking care of the bearings helps the spindle stay accurate for a long time.

Durability

Super precision angular contact ball bearings last a long time in tough jobs. They are strong because of good materials, careful making, and the right oil. The table below lists things that help bearings last longer:

| Factor | Impact on Durability and Performance |

|---|---|

| Lubrication | Reduces friction and heat, enabling higher speeds and longer life. |

| Heat Management | Prevents heat-related damage, maintaining bearing integrity at high speeds. |

| Precision & Alignment | Minimizes operational stress and vibration, enhancing lifespan and reliability. |

| Environmental Factors | Maintains stable operation and prevents premature wear or failure. |

| Material Choice | Improves wear resistance and thermal stability, extending service life. |

| Preload Settings | Enhances rigidity, reduces noise, and prevents skidding at high speeds. |

| Thermal Management | Preserves bearing geometry and function under thermal stress. |

| Load Conditions | Ensures bearings operate within design limits, preventing overload. |

| Bearing Design | Matches configuration to needs, optimizing durability and performance. |

If used right, these bearings in fast spindles can last 20,000 to 30,000 hours. Their strong build and careful setup help stop early problems, even in hard places.

Selection and Handling

Choosing the Right Bearing

Picking the right angular contact bearing helps the spindle work well and last longer. Engineers need to match the bearing to the spindle’s speed, how much weight it carries, and where it will be used. The table below shows what is important for spindle bearings:

| Criterion | Importance |

|---|---|

| Precision Class | Stops the spindle from moving wrong and keeps it steady at high speeds. |

| Contact Angle | Makes sure the weight is spread out evenly. |

| Cage Design | Lowers rubbing and damage, which helps at fast speeds. |

| Heat Dissipation | Stops heat from hurting the bearing and keeps it working right. |

| Load Capacity | Makes sure the bearing can hold the right amount of weight. |

| Speed Requirements | Lets the spindle spin fast without getting too hot. |

| Rigidity & Precision | Keeps the shaft in the right place and helps make good parts. |

| Environmental Conditions | Lets the bearing work even if there is dust, water, or chemicals. |

| Lubrication Type | Helps lower rubbing and keeps the bearing cool. |

| Preloading | Makes the bearing stiffer and takes away extra space. |

Engineers also think about what kind of weight the spindle will hold, how exact it needs to be, and how easy it is to put in. Bearings with high precision, like ABEC 7 or ISO P4, help stop shaking and make the spindle work better.

Installation Tips

Putting in the bearing the right way stops it from breaking early. Clean all parts with a cloth that does not leave fuzz and use cleaner before putting the bearing in. Always check if the shaft and housing are lined up so the weight is even. Use special tools that only push on the bearing rings, not the balls inside. Warm the bearing rings to 80–100°C to make them easier to put on, but do not get them too hot. Use a torque wrench to tighten bolts to the right amount, just like the maker says. Set the preload between 0.1% and 0.6% of the bearing’s load rating to make it stiff enough. Look at the bearings for any damage before you put them in. Be gentle with all parts so you do not make dents or scratches.

Tip: Do not open sealed bearing packages until you are ready to use them. This keeps dirt out.

Lubrication and Maintenance

Lubrication is very important for keeping bearings working well and lasting a long time. Oil-air systems give small drops of oil, which helps at fast speeds and keeps things cool. Grease works better for slower spindles and does not need as much care. Only fill the bearing with 30–50% grease so it has room to grow when it gets hot. Always use good oil or grease that the maker says is okay. Check the oil and how hot the bearing gets every three to six months. Keep the area clean so dust and water do not get inside. Good seals keep dirt out and help the oil or grease last longer. Check the bearings and listen for shaking to find problems early and fix them before they get worse.

Note: Taking care of bearings and using the right oil or grease helps them last longer and keeps the spindle working well.

Precision angular contact bearings help spindles work well and stay strong, even in tough places. Engineers get better results when they pick the right bearing, set it up the right way, and take care of it.

- Being careful at each step helps machines work better and last longer.

- If you need help or want good spindle parts, TFL Bearings can help you.

FAQ

What makes angular contact bearings suitable for high speed spindles?

Angular contact bearings can hold both side and end loads. Their shape helps them stay steady and precise when spinning fast. Engineers pick them for spindles because they lower shaking and keep things accurate, even when running quickly.

How does preload affect spindle ball bearings?

Preload makes spindle ball bearings stiffer. It takes away extra space inside the bearing. This helps stop shaking and makes the bearing more exact. The right preload lets the bearing hold heavy end loads and work well at high speeds.

Why do engineers select super precision angular contact ball bearings for machine tools?

Super precision angular contact ball bearings are very exact and have little rubbing. They can spin fast and hold heavy end loads. These bearings help machines make parts that fit well and work right, even in tough jobs.

What is the difference between single row and double row angular-contact ball bearings?

Single row angular-contact ball bearings hold end load from one side only. Double row bearings can hold end load from both sides and are stiffer. Double row types are used when machines need to be steady and carry more weight.

How often should precision ball bearings in spindles receive maintenance?

Precision ball bearings in spindles should be checked every three to six months. Good oil and regular checks help stop early problems. Keeping things clean and handling bearings right helps them last longer and stay accurate.