Premium Industrial Bearings | Fast Delivery & Affordable | TFL Bearings

Chinese Bearing Suppliers, Serving Globally.

Delivered Over 28 Million Bearings

Eectrically Insulated Bearings

- Reduce Downtime

- Profit

- Interchangeable

- After-sales Service

- Ensure Authenticity

FEATURED PRODUCT CATEGORIES

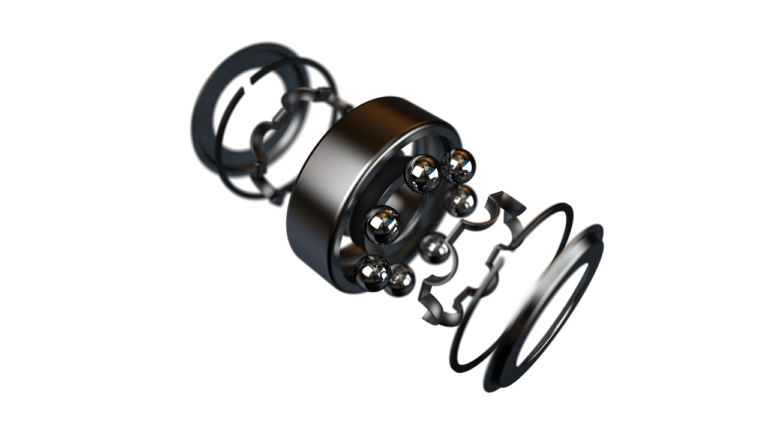

Precision-engineered for excellence, TFL BEARING’s ball bearings are one of the most versatile and efficient solutions on the market. We utilize premium-grade materials and advanced manufacturing processes to ensure every bearing delivers low friction, long service life, and reliable performance under both radial and axial loads. Critically, TFL ball bearings are manufactured to international standards, making them perfectly interchangeable with top-tier brands like SKF, FAG, and NSK, offering you a high-value, reliable alternative.

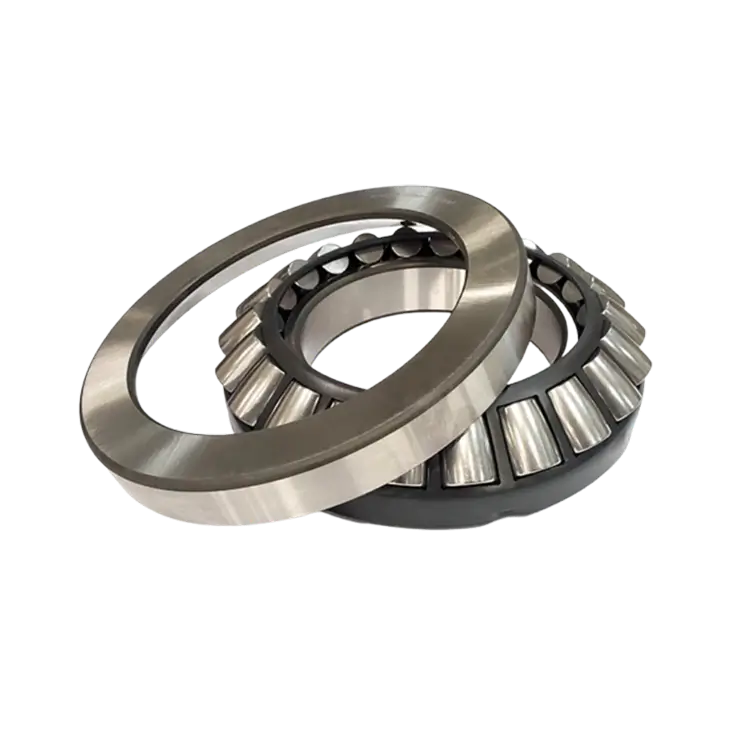

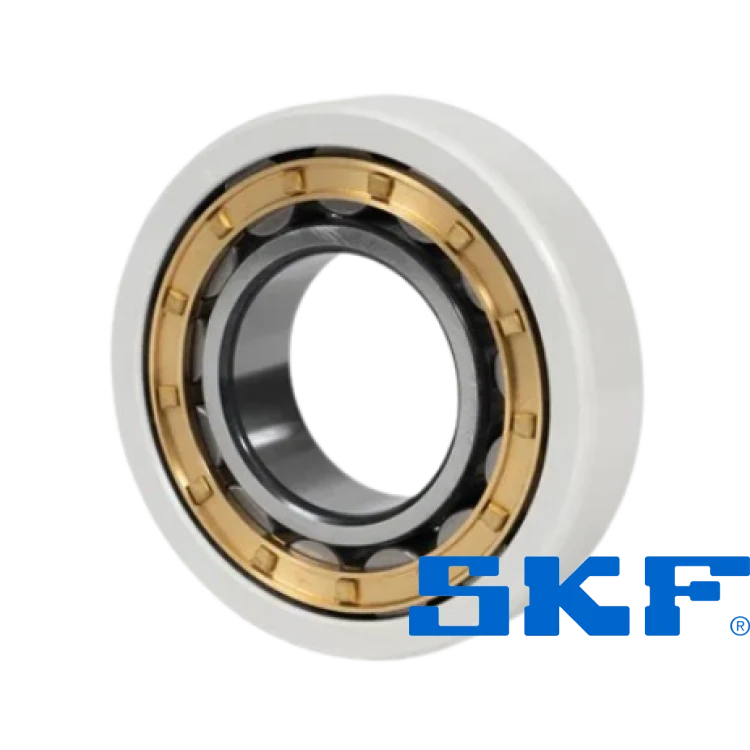

When your application demands extreme heavy-load capacity, TFL BEARING’s roller bearings are your most robust and reliable choice. Featuring an optimized line-contact design, our roller bearings deliver unmatched radial load capacity and superior rigidity, built to thrive in the toughest industrial environments. We guarantee that every TFL roller bearing undergoes rigorous quality control, ensuring its performance and dimensions can match or exceed industry benchmarks, providing you with worry-free operation under the harshest conditions.

In motor and generator applications, stray electrical currents are the “silent killer” leading to premature bearing failure. TFL BEARING’s electrically insulated bearings are the ultimate solution to this challenge. We utilize advanced plasma spray technology to apply a dense, uniform, and superiorly insulating aluminum oxide ceramic coating—a protective layer that far exceeds industry standards. This not only fundamentally eliminates electrical erosion damage but also significantly extends your equipment’s service life, maximizing operational efficiency and reducing maintenance costs.

OUR ADVANTAGES

ABOUT TFL

Company Capabilities

Product Advantages

Customized Solutions

Reliable Service Assurance

APPLICATION AREA

OPTIMIZE YOUR BEARING PROCUREMENT COSTS

WHY CHOOSE TFL

QUALITY

PRICE

FAST DELIVERY

CUSTOMER REVIEWS AND CASE STUDIES

FREQUENTLY ASKED QUESTIONS

Is there a Minimum Order Quantity (MOQ)?

Why can TFL bearings replace internationally renowned brands such as SKF and FAG?

TFL Bearings offers SKF/FAG-level quality, 15%–25% lower cost, 3–5 day delivery, 24-hour support, and certified innovation—making it the cost-effective replacement choice.

How do you handle international shipping and logistics? Do I need to arrange it myself?

What payment methods do you accept?

- Credit/Debit Cards: We accept Visa, Mastercard, and American Express.

- Online Payments: Alipay and WeChat Pay.

- Bank Transfer: Please contact your sales representative for our bank account details.

- Telegraphic Transfer (T/T) and Letter of Credit (L/C): We accept standard international payment methods such as Telegraphic Transfer (T/T). For specific orders, Letter of Credit (L/C) may also be accepted.

- Payment terms typically involve a percentage deposit upfront, with the balance paid before shipment. Specific terms can be discussed based on order details.

Return & Refund Policy

- All returned items must be in their original packaging, unused, undamaged, and in a condition suitable for resale.

- Proof of purchase must accompany all returns without exception.

What shipping methods do you offer?

NEWS

When to Replace a Bearing: Early Warning Signs and Maintenance Tips

This guide outlines the critical warning signs of bearing failure, such as noise, vibration, and heat. It explains the root causes of damage and provides actionable maintenance tips to help you determine exactly when to replace a bearing to ensure operational efficiency.

Why Proper Bearing Lubrication Matters: Types, Methods, and Maintenance Tips

This article explores the critical role of bearing lubrication in reducing friction and preventing failure. It covers the differences between grease and oil, proper application methods, common mistakes to avoid, and maintenance strategies to ensure industrial machinery operates efficiently.

Cylindrical Roller Bearings vs Needle Roller Bearings: A Detailed Comparison

This technical guide provides a side-by-side comparison of cylindrical vs needle roller bearings, analyzing their structural differences, load capacities, and speed limitations. It offers engineers and buyers practical advice on selecting the right bearing type to optimize machinery performance and space efficiency.

Angular Contact Ball Bearings: Features, Benefits, and Best Applications

This article explores the design, functionality, and benefits of angular contact ball bearings, highlighting their ability to handle combined loads in high-speed industrial applications like robotics and automotive systems.